Plate-frame type containers, and open top wagon carriage and flat car equipped therewith

A container and plate-frame technology, applied in trucks, packaging, transporting passenger cars, etc., can solve the problem of the absence of heavy cylindrical goods, and achieve the effect of reducing the use of reinforcement materials, reducing the number of production, and widening the diameter range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. The same components are denoted by the same reference numerals in the drawings.

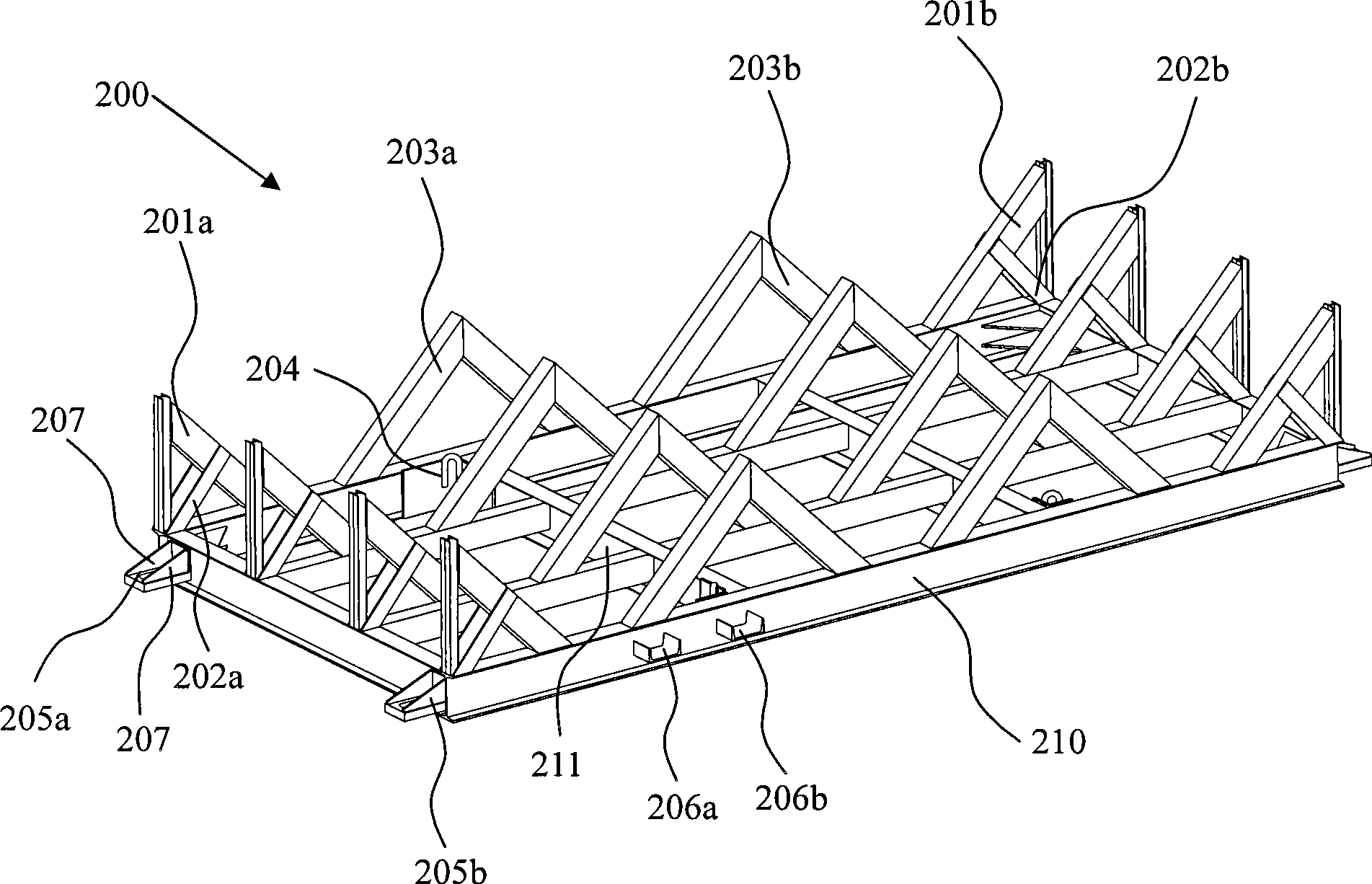

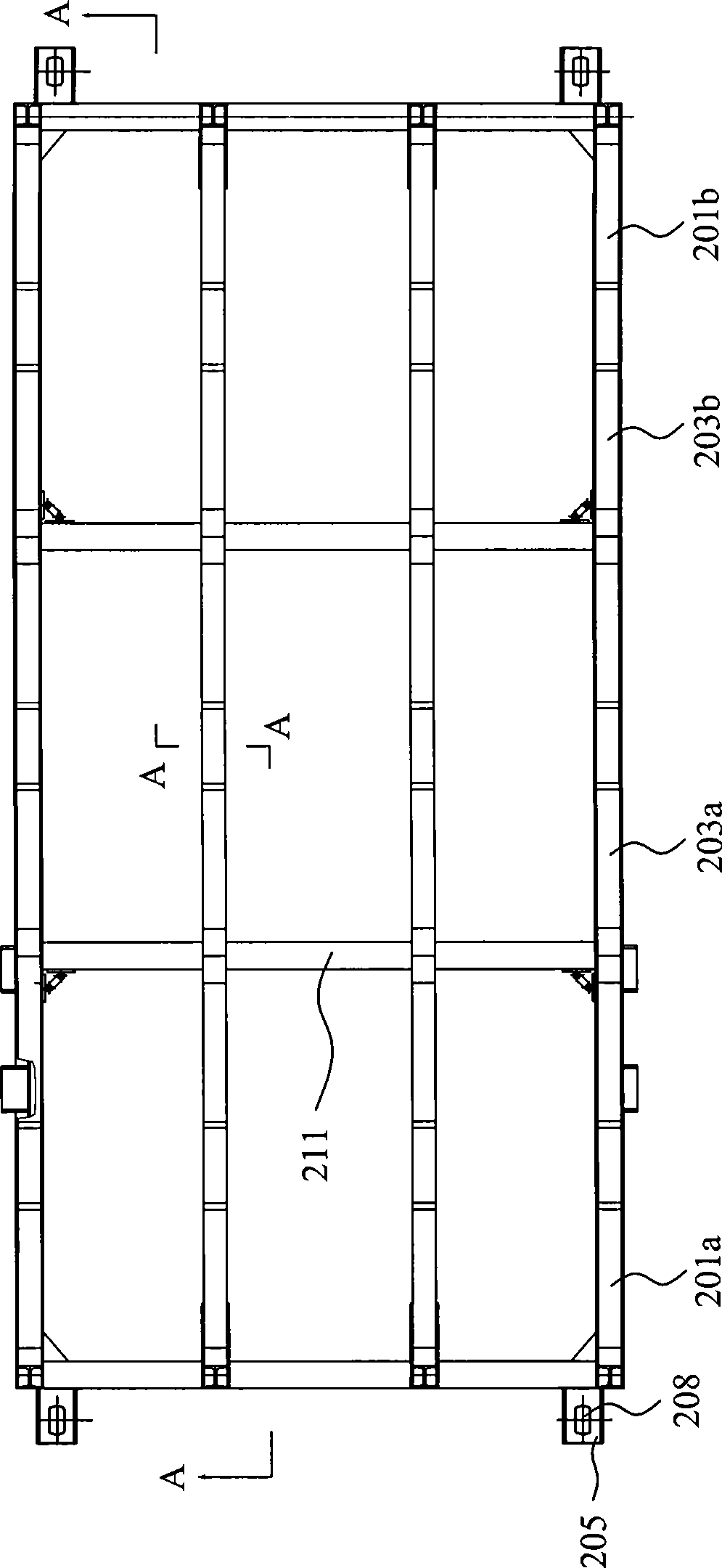

[0035] Such as Figure 2-Figure 4 As shown, the pallet container 200 according to the embodiment of the present invention includes an underframe 210, multiple rows of blocking members 201a, 201b, 203a, 203b, first connecting members 205a, 205b, lifting ring 204, and second connecting members 206a, 206b.

[0036] The chassis 210 is preferably welded from profiles. On the one hand, the base frame 210 serves as a base frame for arranging multiple rows of blocking pieces 201 a , 201 b , 203 a , 203 b , second connecting pieces 206 a , 206 b , first connecting pieces 205 a , 205 b , and suspension rings 204 . On the other hand, the underframe 210 can evenly transmit the loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com