Hydraulic time-delay double-stage braking hoister hydraulic station

A secondary brake and hoist technology, applied in hoisting devices and other directions, can solve the problems of primary brake pressure instability, poor pressure holding performance, short delay time, etc., and achieve reliable secondary brake performance and easy debugging Simple, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

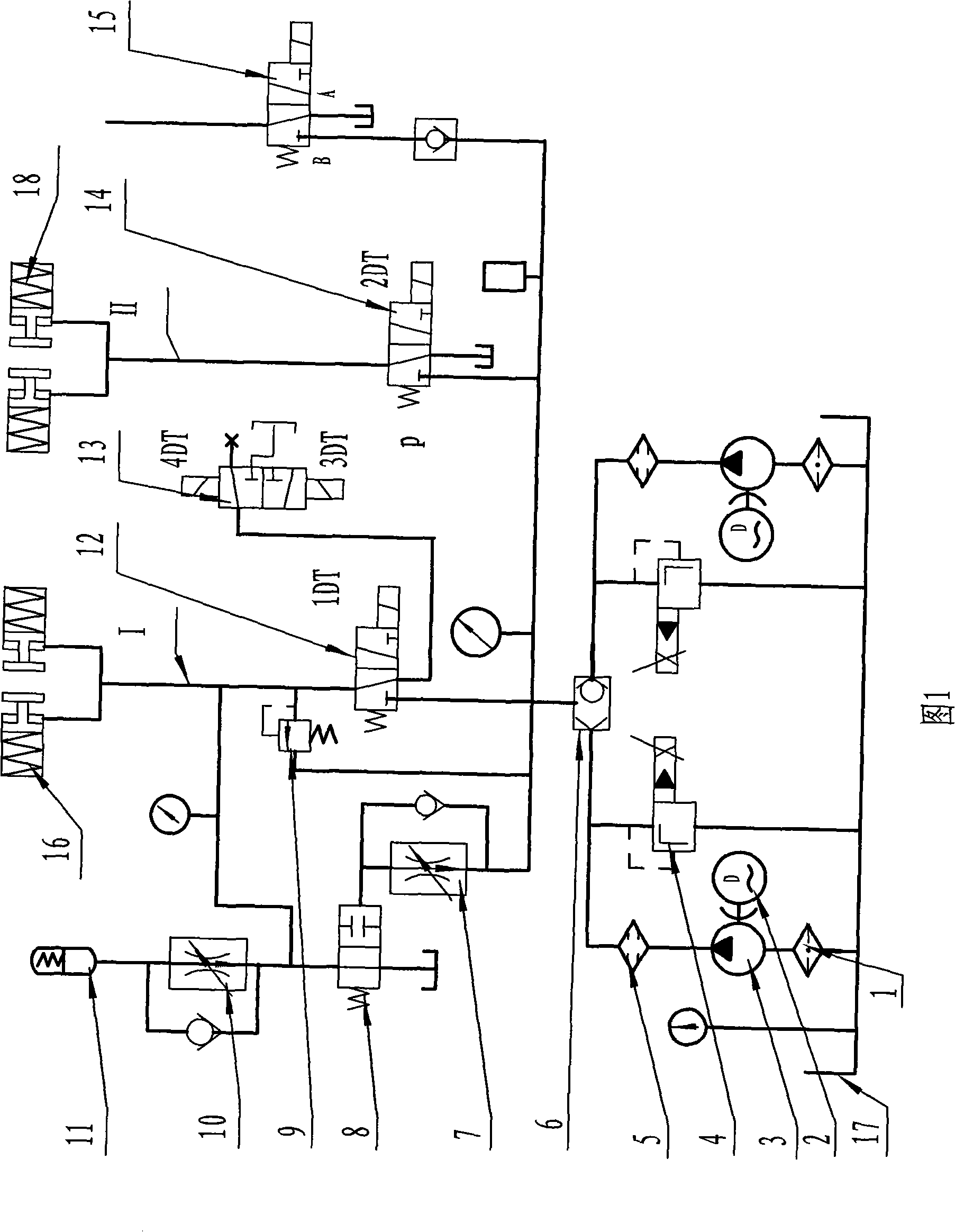

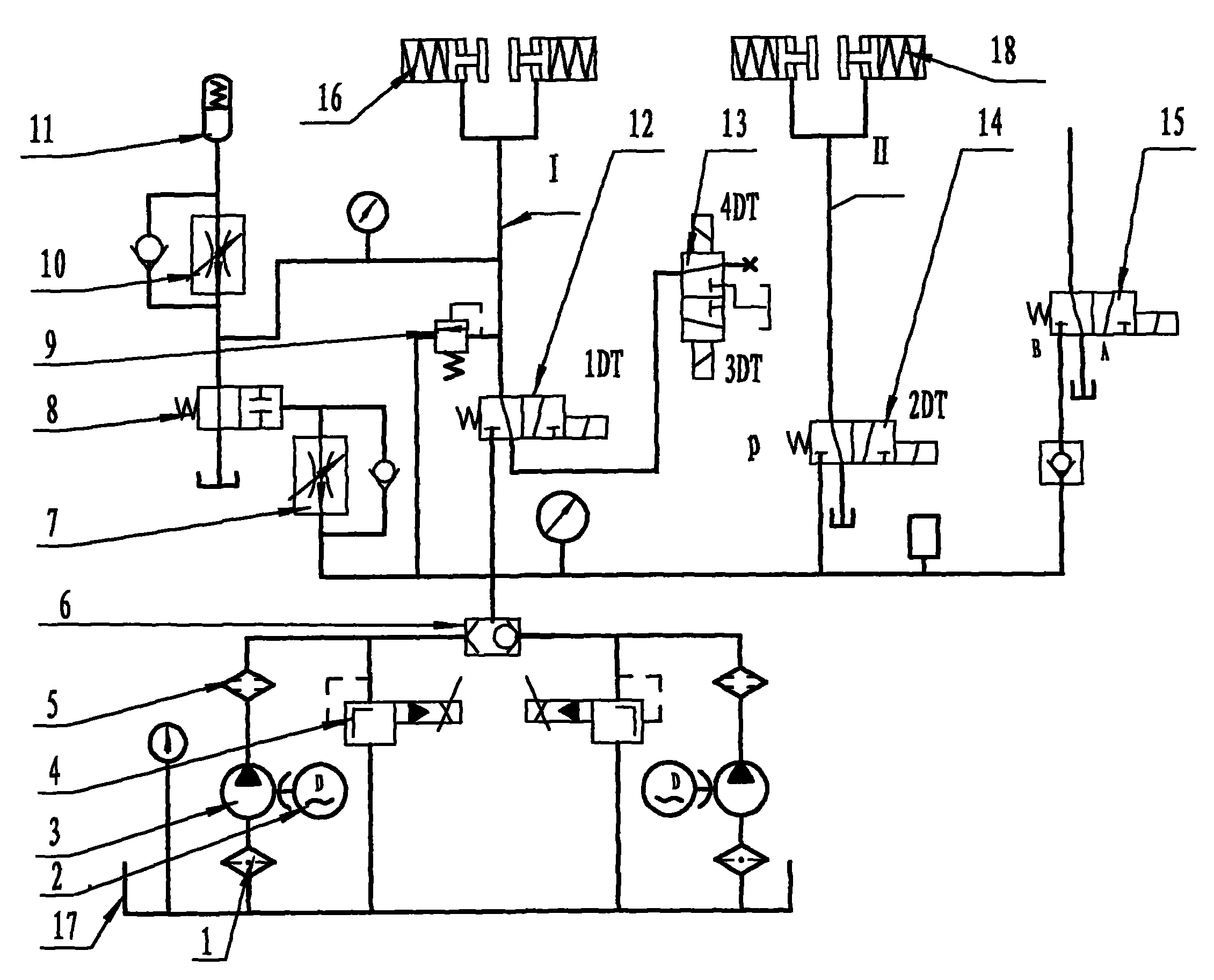

[0012] see figure 1 In the hydraulic station of the hydraulic time-delay secondary brake hoist of the present invention, the motor 2 is electrically connected to the oil pump for driving the oil pump 3, and the oil inlet end of the oil pump is connected to the oil coarse filter 1 for filtering hydraulic oil. The oil outlet end of the oil pump is connected with a fine filter 5 to further filter the hydraulic oil to ensure the cleanliness of the hydraulic oil entering the entire hydraulic station. The oil outlet of the oil pump is connected with a proportional relief valve 4 on the oil circuit. According to the above settings, the hydraulic station consists of 2 motors, oil pumps, coarse and fine filters, proportional relief valves, and a shuttle valve 6 connected between the 2 proportional relief valves and the common oil circuit at the oil pump outlet to form a dual power source Dual control system. The shuttle valve is connected with the first brake 16 through the first ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com