Turning spherical support

A technology of spherical bearings and swivels, which is applied to bridge parts, bridges, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

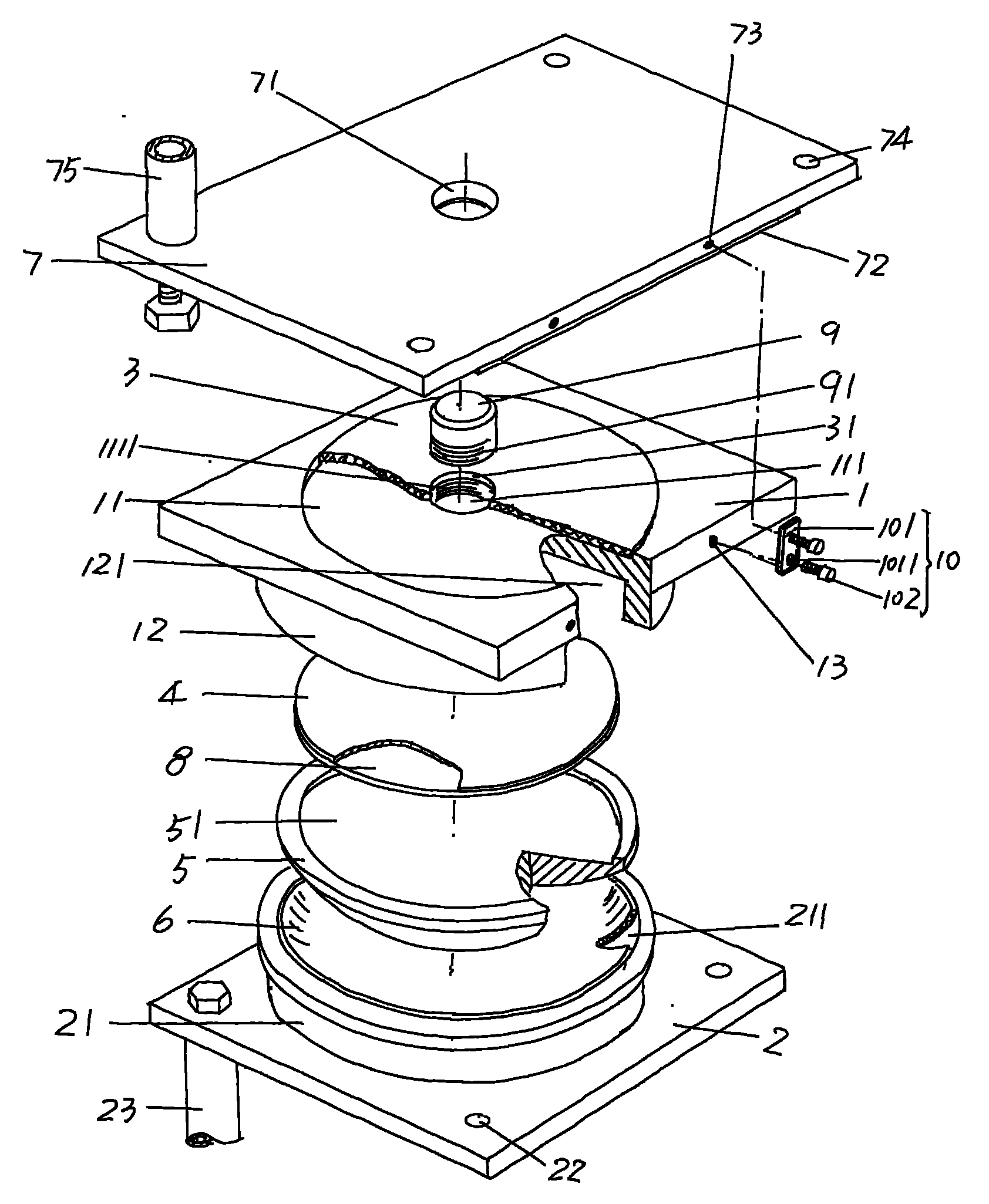

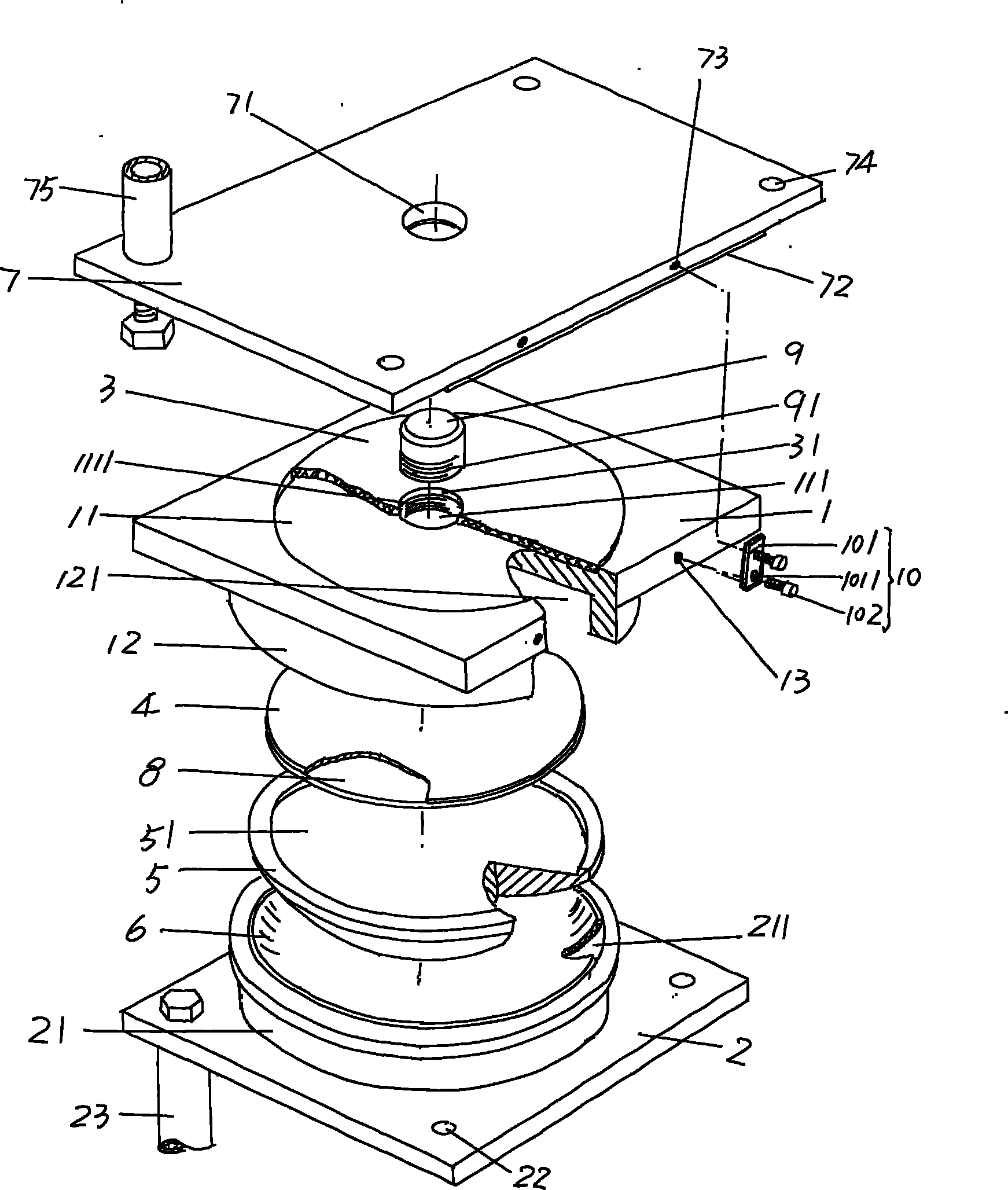

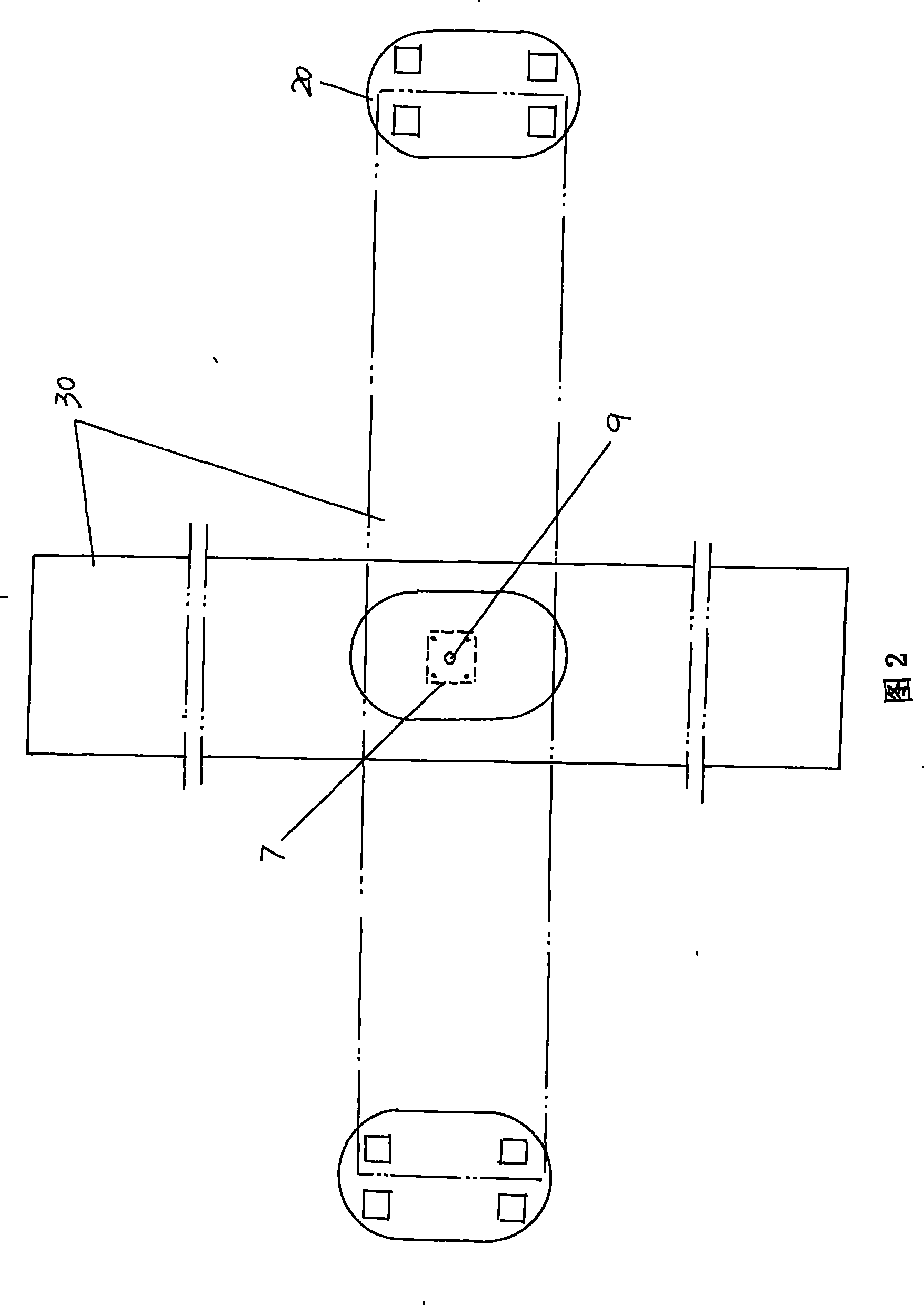

[0022] Please refer to Fig. 1, according to the known common sense, the lower support plate 2 is fixed with the pier 20 (shown in Fig. 2) of the bridge, specifically: the number of the lower support plate 2 is not limited by the first The fixing member hole 122 is inserted into the first fixing member hole 22 by a group of first fixing members 23 and fixed with the embedded parts on the pier 20 . The specific shape of the lower support plate 2 is not limited by the illustration, and the central area of the side of the lower support plate 2 facing the upper support plate 1, that is, the upper side of the lower support plate 2 in the state shown in the present illustration The central region forms a ring-shaped first edge 21, and a spherical concave cavity 211 is formed in the first edge 21, and the spherical concave cavity 211 is arranged, that is, the paving shape is basin-shaped and is preferably made of polytetrafluoroethylene material. The third anti-friction plate 6 form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com