Test method for anti-permeability performance of fluid sealant and concrete bonding sample interface

A technology of bonding samples and testing methods, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as bad social impact, foundation subsidence, and damage to concrete structures, and achieve easy promotion, convenient use, and operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

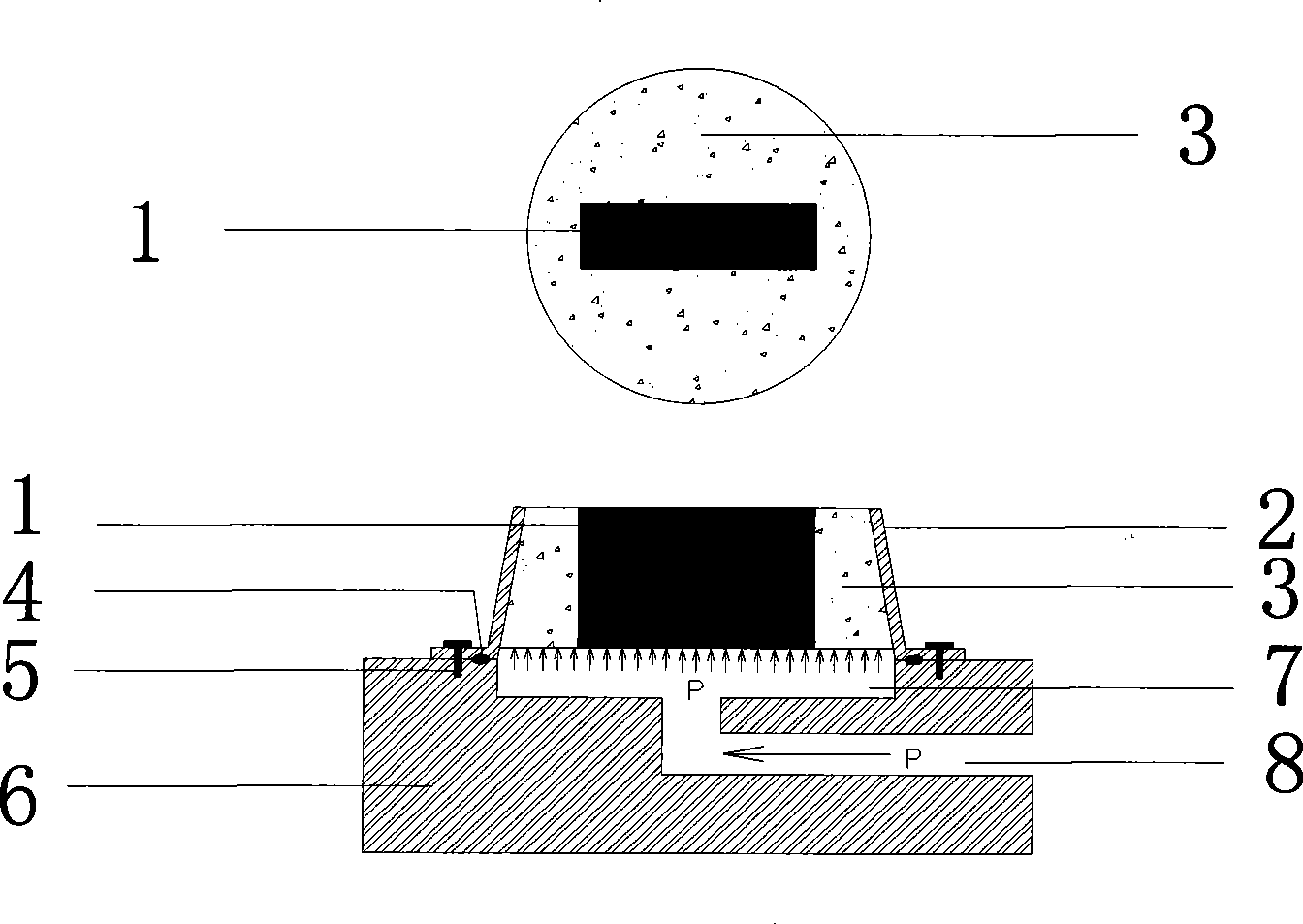

[0013] see figure 1 According to the technical scheme of the present invention, the test method of the interface impermeability of the sealant and the concrete bonding sample comprises the following steps:

[0014] 1. First, prepare a bonded anti-seepage sample. The concrete anti-seepage sample is in the shape of a truncated cone, with a large bottom and a small top as a whole. It is made of concrete 3 and sealant 1. Sealant 1 is located in the middle of concrete 3, and It is completely covered by the concrete 3 and forms a whole with the concrete 3, and the anti-seepage layer is applied around the bottom and outside of the concrete part of the impermeable sample;

[0015] 2. Place the bonded anti-seepage sample in the outer steel mold 2, and fix it on the water pressure chamber 7 of the anti-seepage instrument 6 through the rubber washer 4 with fastening bolts 5, so that the bonded anti-seepage sample and the anti-seepage instrument The water pressure chamber 7 of 6 is imper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com