Microwave hot vapor de-icing apparatus and de-icing method

A superheated steam and microwave technology, used in overhead installation, cable installation, electrical components, etc., can solve problems such as low deicing efficiency and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

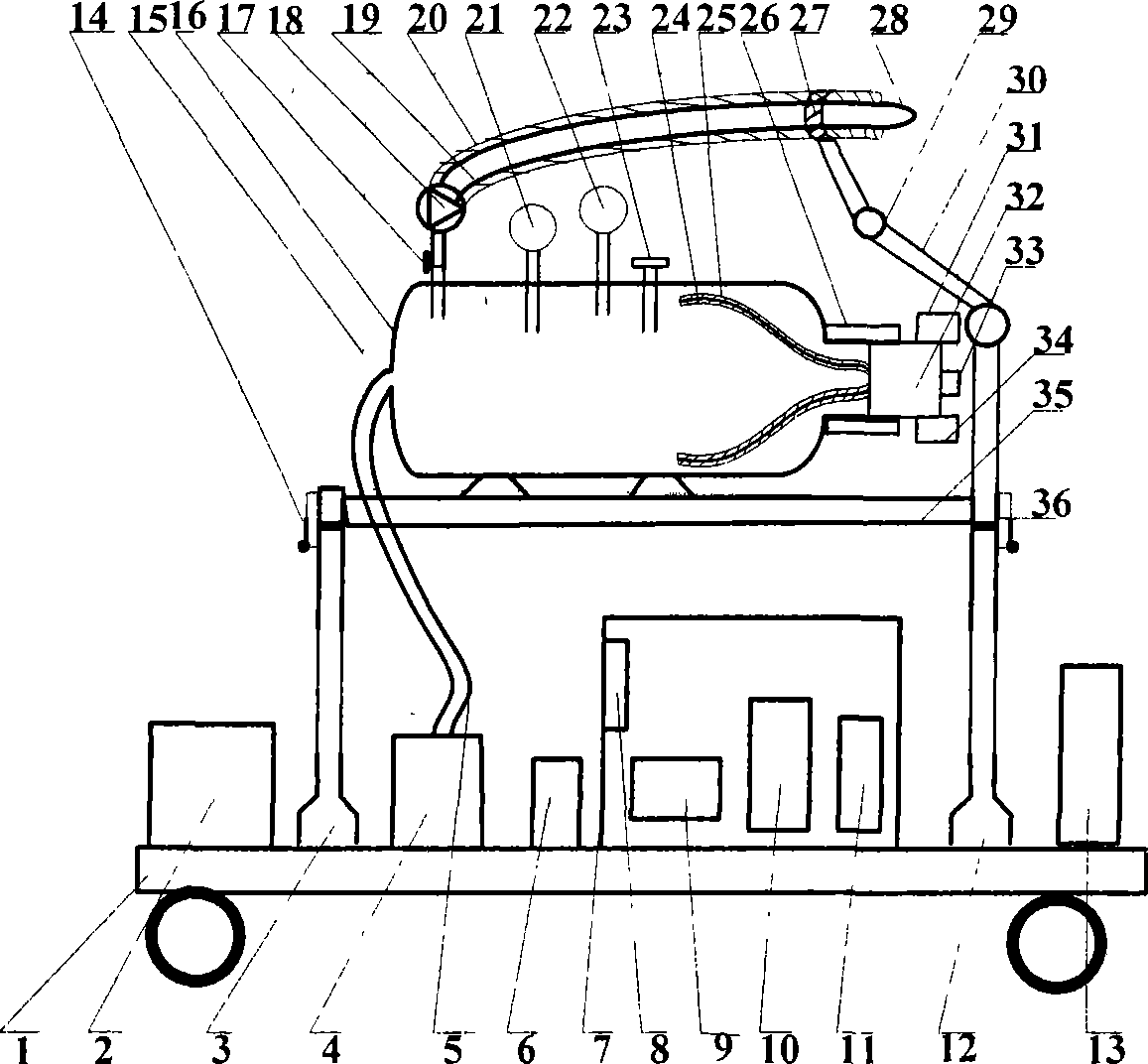

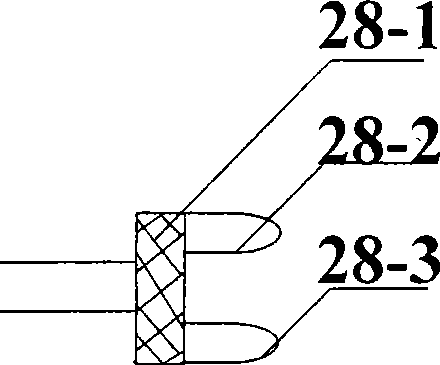

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the device of the present invention is mainly composed of a mobile device 1, a microwave power supply 7, a microwave superheated steam box 15 and a mobile injection device. The microwave superheated steam box 15 is mainly composed of a heating kettle 16, a magnetron 32, a microwave antenna 24, an injection pipe 20, and a nozzle 28. The mobile spraying device includes a mechanical pole arm 30 , an electric rotating shaft 29 , a first telescopic control system 14 , a fixed bracket 27 , a fixed plate 35 , and a second telescopic control system 36 .

[0014] In consideration of improving irradiation efficiency, convenient operation, and minimizing energy transmission loss, the device of the present invention adopts an excitation reflection output mode to directly connect the magnetron 32 and the microwave antenna ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com