Roller die squeezing type granulator

An extrusion and granulator technology, applied in the direction of die extrusion granulation, etc., can solve the problem of undetermined cooling temperature range, shortening the service life of gears, and increasing frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

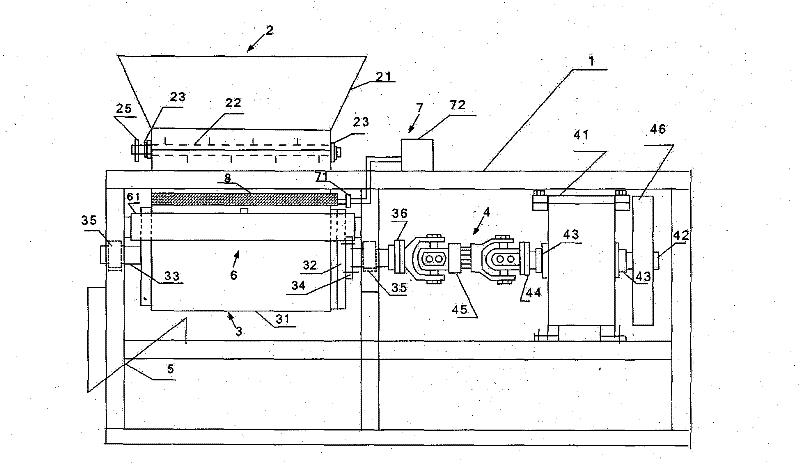

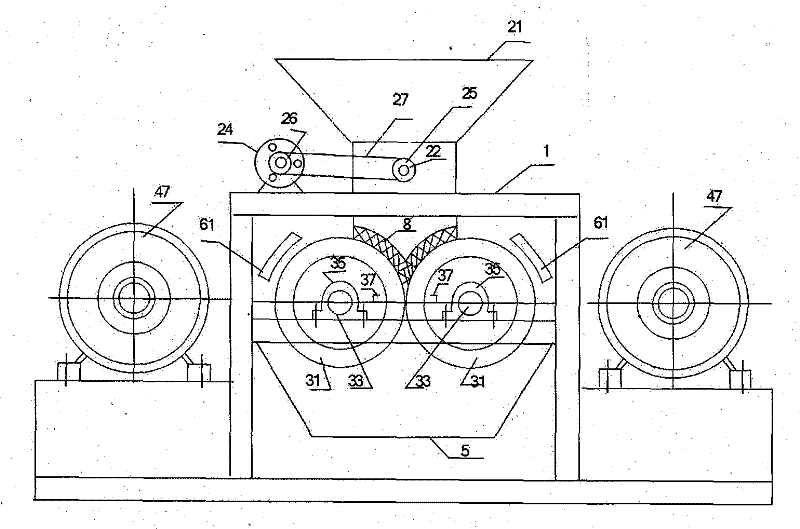

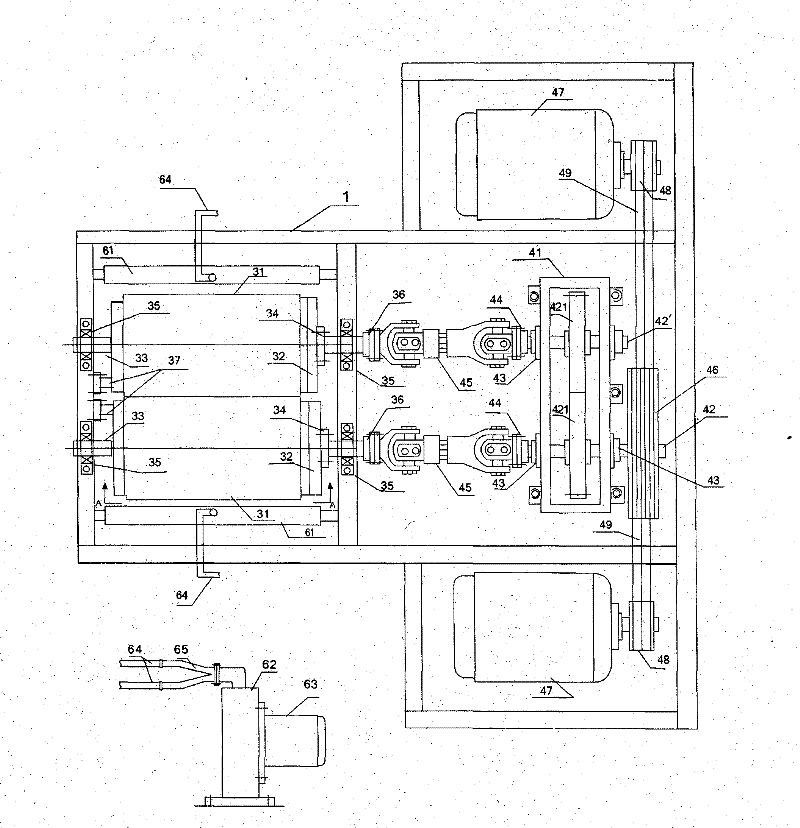

[0012] Figure 1 to Figure 3 with Figure 5The roller die extrusion granulator shown includes a frame 1, a feeding device 2, a granulation device 3, and a power drive device 4, placed under the discharge end of the granulation device 3 and connected and fixed on the frame 1 The discharge hopper 5, the air-cooled cooling device 6, the temperature control device 7, the sealing lining 8, 8'; the feeding device 2, it includes the feeding hopper 21, the wing blade shaft 22, two sets of bearing shell boxes 23, 23, speed-regulating motor 24, No. 1 and No. 2 belt pulleys 25, 26, a group of belts 27; the wing blade shaft 22 is placed in the feed hopper 21, and two sets of bearing tile boxes 23, 23 are connected to the two ends of the wing blade shaft 22 respectively. The neck and the feeding hopper 21 are connected and fixed at the outer center of the lower part of the corresponding two plug side walls. The speed regulating motor 24 is placed on the side of the feeding hopper 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com