Vibration reduction and explosion reduction split type imported energy dissipation device

An energy-dissipating, split-type technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as vibration of the middle partition wall, high water flow velocity, and the impact of surrounding residents, so as to improve safety and operational safety. performance, weakening the risk factor of cavitation damage, and avoiding the effect of cavitation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

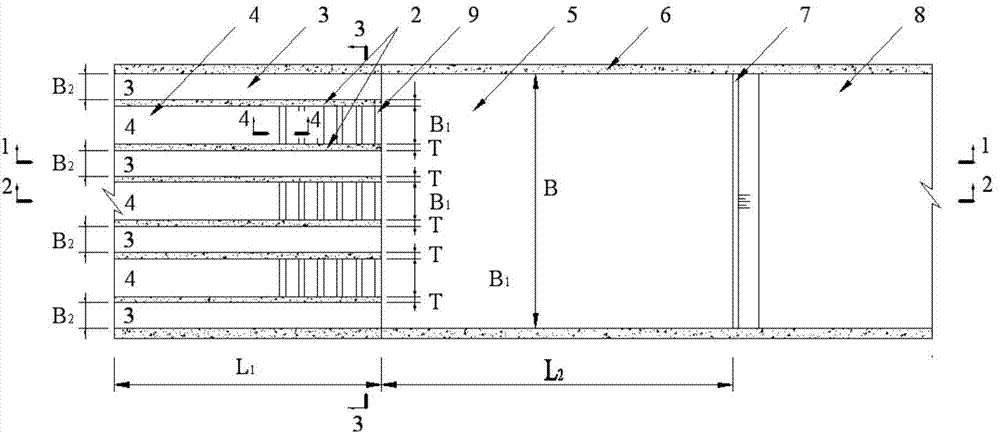

[0036] The split-type imported energy dissipator for vibration reduction and explosion reduction in this embodiment is a differential split-type imported energy dissipator, and its structure is as follows figure 1 , Figure 10 , Figure 11 with Figure 15 As shown, it includes a water flow chute section, a stilling basin 5 connected to the water flow chute section, and an apron 7 connected to the stilling basin. Hole drain 3 and middle hole drain 4, a connecting beam 9 is arranged between the two groove walls of each middle hole drain, and the two ends of the connecting beam are respectively fixed on the two groove walls of the middle hole drain 4 , connect the partition walls. There are 5 surface hole drains, the width of which is B 2 =4m, there are 4 middle-hole chute, and its width B 1 =6m, middle partition wall thickness T=3m, stilling basin width B=52m, depth H from the outlet of surface hole chute to stilling basin bottom plate 3 =16m, the depth H from the outlet o...

Embodiment 2

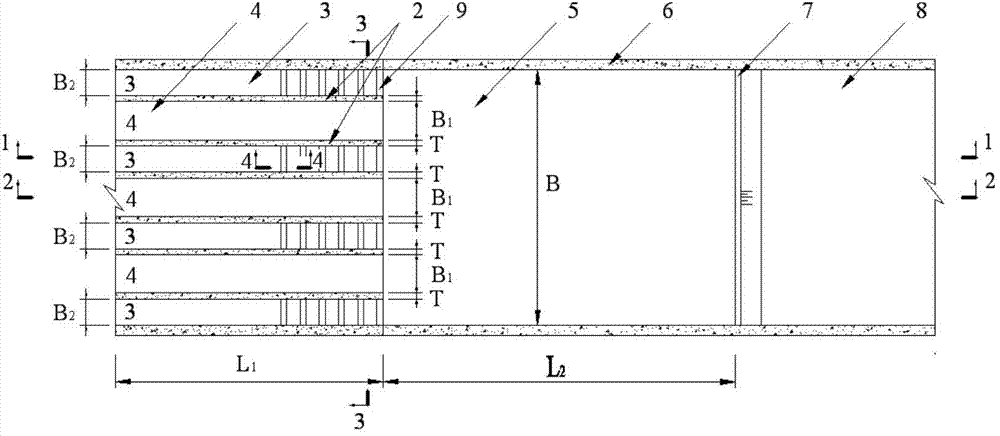

[0039] The split-type imported energy dissipator for vibration reduction and explosion reduction in this embodiment is a differential split-type imported energy dissipator, and its structure is as follows figure 2 , Figure 9 , Figure 12 with Figure 15 As shown, it includes a water flow chute section, a stilling basin 5 connected to the water flow chute section, and an apron 7 connected to the stilling basin. Hole drain 3 and middle hole drain 4, a connecting beam 9 is arranged between the two groove walls of each surface hole drain, and the two ends of the connecting beam are respectively fixed on the two groove walls of the surface hole drain 3 , connect the partition walls. There are 5 surface hole drains, the width of which is B 2 =4m, there are 4 middle-hole chute, and its width B 1 =6m, middle partition wall thickness T=3m, stilling basin width B=52m, depth H from the outlet of surface hole chute to stilling basin bottom plate 3 =16m, the depth H from the outlet...

Embodiment 3

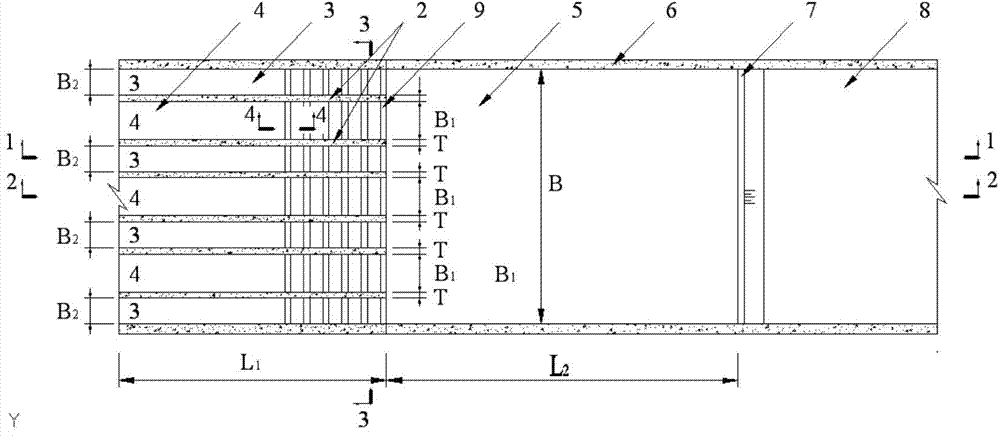

[0042] The split-type imported energy dissipator for vibration reduction and explosion reduction in this embodiment is a non-differential split-type imported energy dissipator, with a structure such as image 3 , Figure 4 , Figure 5 , Figure 8 with Figure 14 As shown, it includes a water flow chute section, a stilling basin 5 connected to the water flow chute section, and an apron 7 connected to the stilling basin. Hole discharge groove 3 and middle hole discharge groove 4, connecting beam 9 is arranged between the two groove walls of each surface hole discharge groove 3 and the middle hole discharge groove, and the two ends of the connection beam are respectively fixed on the surface hole discharge groove 3 and the two groove walls of the middle hole discharge groove 4, the middle partition wall is connected. There are 5 surface hole drains, the width of which is B 2 =4m, there are 4 middle-hole chute, and its width B 1 =6m, middle partition wall thickness T=3m, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com