Inorganic phosphor

A technology of inorganic fluorescence and main body, applied in the field of inorganic phosphors, which can solve the problems of low absolute light quantity, small light-emitting area, and limited use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] For every 100g ZnS, weigh Ir 2 (SO 4 ) 3 And mix with ZnS so that the amount of Ir element relative to the amount of Zn element is as follows. After mixing in a mortar for 20 minutes or more, it was calcined at 1100° C. for 3 hours in a vacuum. After calcination, the product was pulverized, washed with water and dried to obtain an Ir-containing ZnS phosphor.

[0071] The wavelength and intensity of light emitted by photoluminescence (PL) when the obtained phosphor was excited with ultraviolet rays of 330 nm are shown in Table 1 below.

[0072] Table 1

[0073] Ir 2 (SO 4 ) 3 doping amount PL emission wavelength PL luminous intensity Remark Sample A 0 Not illuminated Not illuminated comparative example Sample B 1E-7mol / molZn 445nm 100 this invention Sample C 1E-6mol / molZn 445nm 800 this invention Sample D 1E-5mol / molZn 445nm 3200 this invention Sample E 1E-4mol / molZn 445nm 1800 this in...

Embodiment 2

[0077] To sample D in Example 1 above, Group XIII-XV compounds were added and mixed in the addition amounts shown below, followed by calcination at 700° C. for 6 hours in vacuum. The results are shown in Table 2 below.

[0078] Table 2

[0079] Ir 2 (SO 4 ) 3 doping amount Doping amount of Group XIII-XV compounds Sample I 1E-5mol / molZn InP; 2E-4mol / molZn Sample J 1E-5mol / molZn InSb; 2E-4mol / molZn Sample K 1E-5mol / molZn GaN; 2E-4mol / molZn

[0080] It can be seen that the luminescence caused by Ir doping is further enhanced by adding a Group XIII-XV compound (including elements of Group 13 and Group 15 of the periodic table). Especially in the case of adding InSb, the PL luminous intensity is the highest.

Embodiment 3

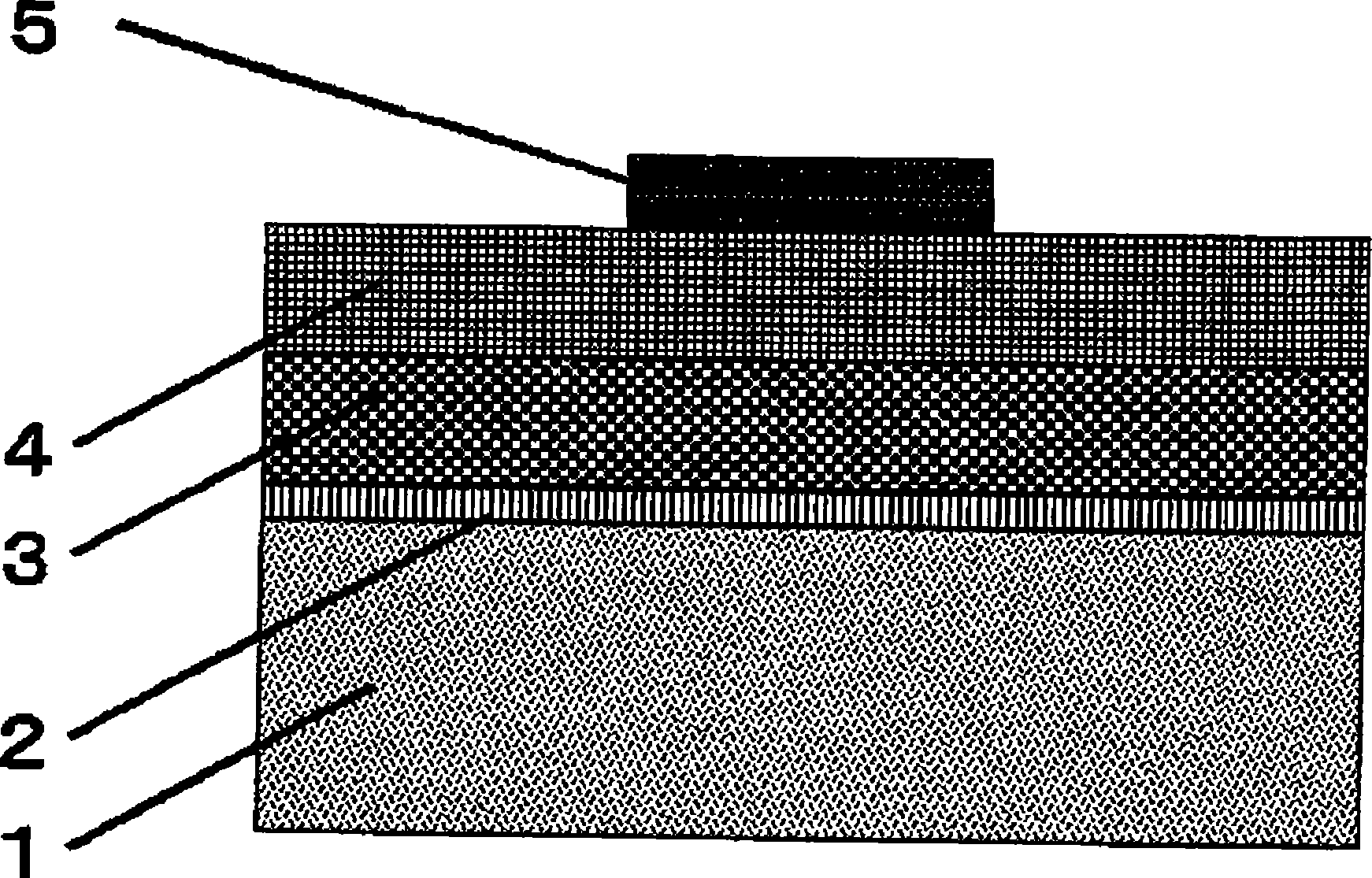

[0082] A DC-driven inorganic EL element was prepared using the inorganic phosphors of Sample D and H to K obtained in Examples 1 and 2 as inorganic fluorescent materials. A schematic structure of a DC-driven inorganic EL element is shown in figure 1 shown.

[0083] Using a transparent glass substrate 1 on which a 200nm-thick ITO as the first electrode 2 was formed by sputtering as a substrate, the inorganic phosphors of samples D and H to K were vacuum-coated by EB vacuum deposition equipment. deposited to form a film on the substrate. More specifically, the inorganic phosphor is set as the first vacuum deposition source, and metal selenium is set as the second vacuum deposition source. Vacuum deposition is performed at a constant film formation rate from the first vacuum deposition source, and for vacuum deposition from the second vacuum deposition source, the first luminescence is formed by making the weight ratio of selenium 0.5% or less in the first half of film formatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com