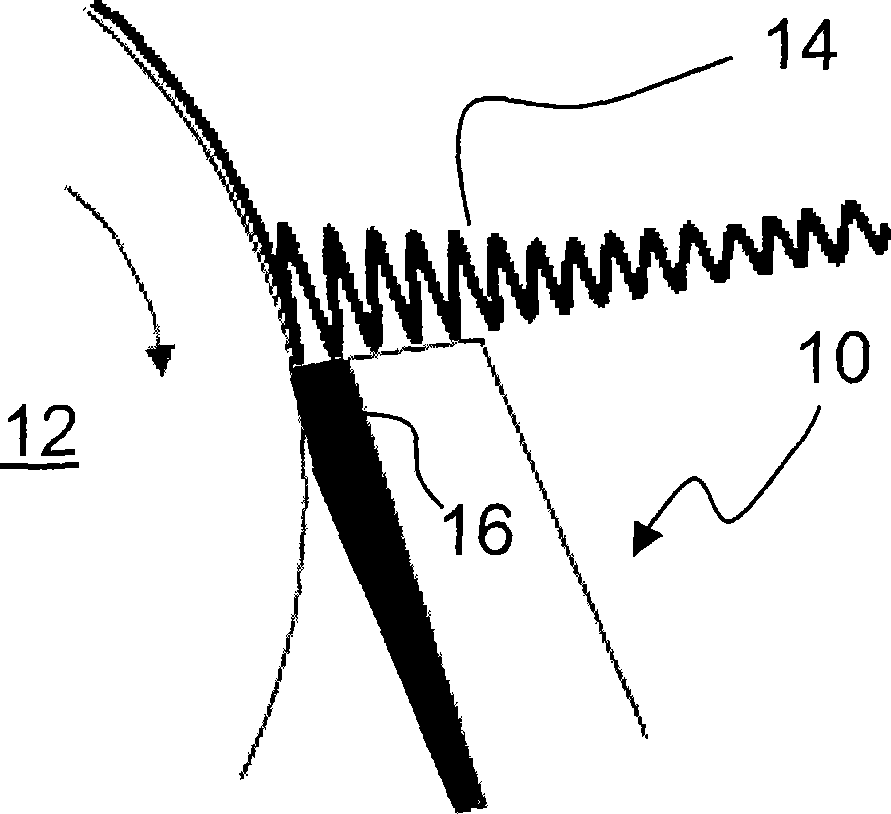

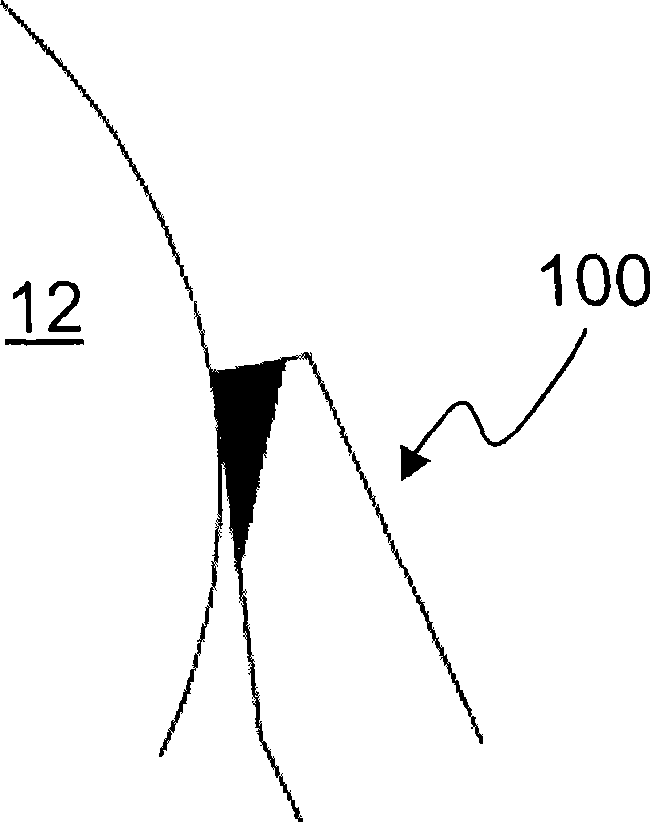

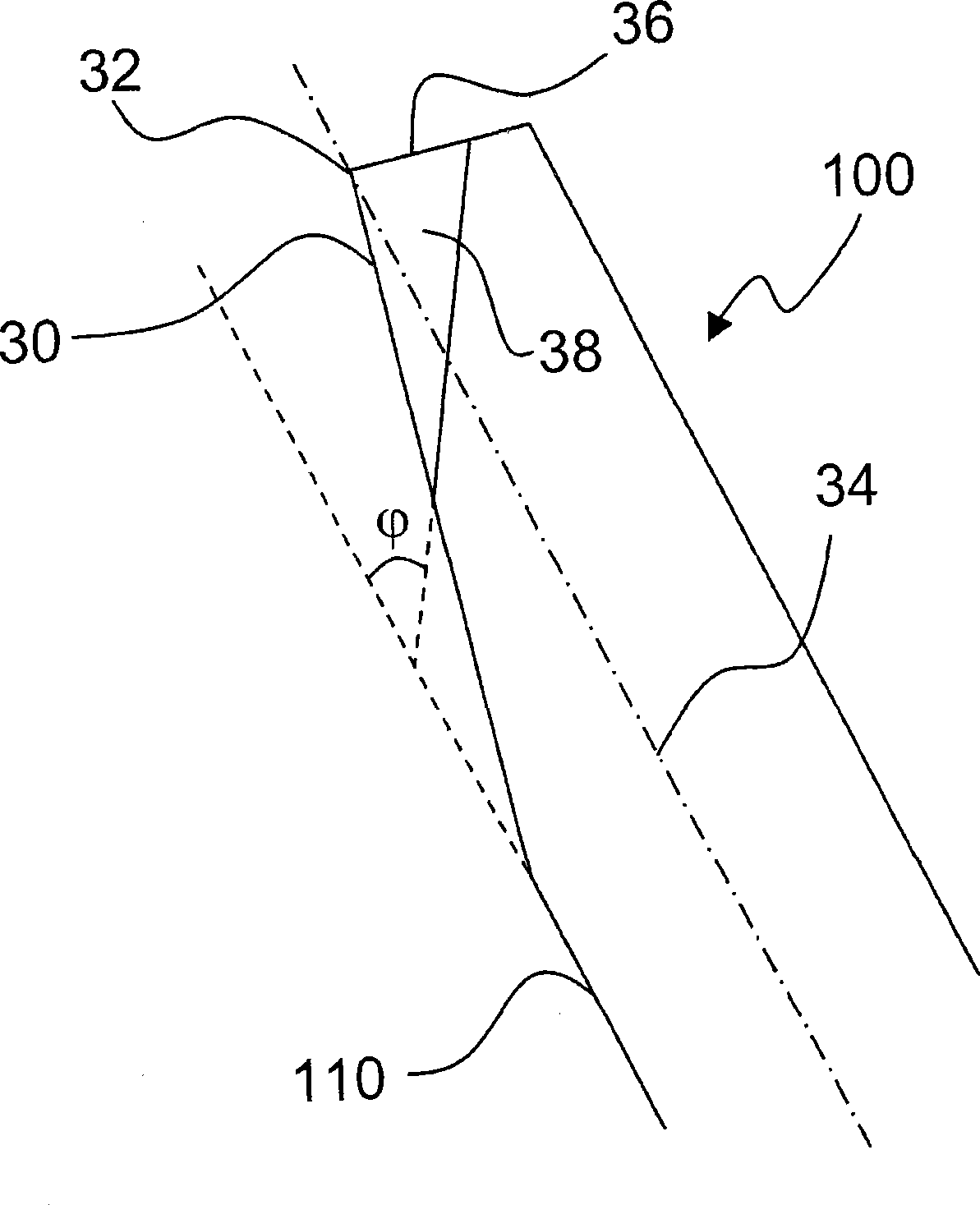

Creping blade

A scraper, apex technology, used in scrapers, textiles and paper, paper machines, etc., can solve problems such as productivity loss, tissue breakage and holes, and achieve the effect of excellent tissue quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] In a paper towel factory, experiments were carried out using three different types of scrapers. The first type (referred to as Type A) is a standard steel spatula, used as a reference. The second type (referred to as Type B) is Applicant's own prior art doctor blade (test blade designated "Proto-173") with a thermally sprayed anti-abrasion material applied to the working tip of the blade for Protect. A third type (referred to as Type C) is an improved coated blade according to the invention using similar wear resistant materials as the type B blades.

[0039] The following operating conditions were used in this test:

[0040] - Paper web made from 100% recycled fibers

[0041] -The final product is industrial toweling tissue (toilet paper)

[0042] - Weight: 27.5g / m 2 (without wet strength agent)

[0043] - Yankee speed: 750-850m / min

[0044] -Reel speed: 655-684m / min (i.e. 15-19.5% wrinkle rate)

[0045] - Yankee surface: cast iron

[0046] - Humidity: 7.0-6.7...

example 2

[0061] On another tissue machine, a comparative test was carried out using two different types of scrapers. The first type (referred to as Type D, with the test blade designated "Proto-C2PGA") was a prior art ceramic blade based on a standard geometry. The second type of doctor blade, referred to as type E, is a ceramic doctor blade according to the invention. Basically, the blade tip geometries of the two test blades were different from each other, but the protective material (ie the anti-abrasion material at the blade tip) was the same for both blades and applied under the same conditions.

[0062] The following operating conditions were used in this test:

[0063] - Paper web made from 100% recycled fibers

[0064] -The final product is industrial toweling tissue (toilet paper)

[0065] - Weight: 17.2g / m 2 (without wet strength agent)

[0066] - Yankee speed: 1470m / min

[0067] - Yankee surface: Voith Endura

[0068] - Humidity: 4.0%

[0069] - Size of crepe scraper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Protrusion length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com