Perpendicular magnetic recording head and method of manufacturing the same

A technology for perpendicular magnetic recording and manufacturing method, which is applied in the directions of magnetic recording heads, magnetic recordings, housings/shields of recording heads, etc., and can solve the problems of increased dispersion field, inability to increase track density, and inability to achieve high-density recording, etc. Achieving good recording characteristics and reducing the effect of scattered fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, preferred embodiments of the present invention will be explained with reference to the drawings.

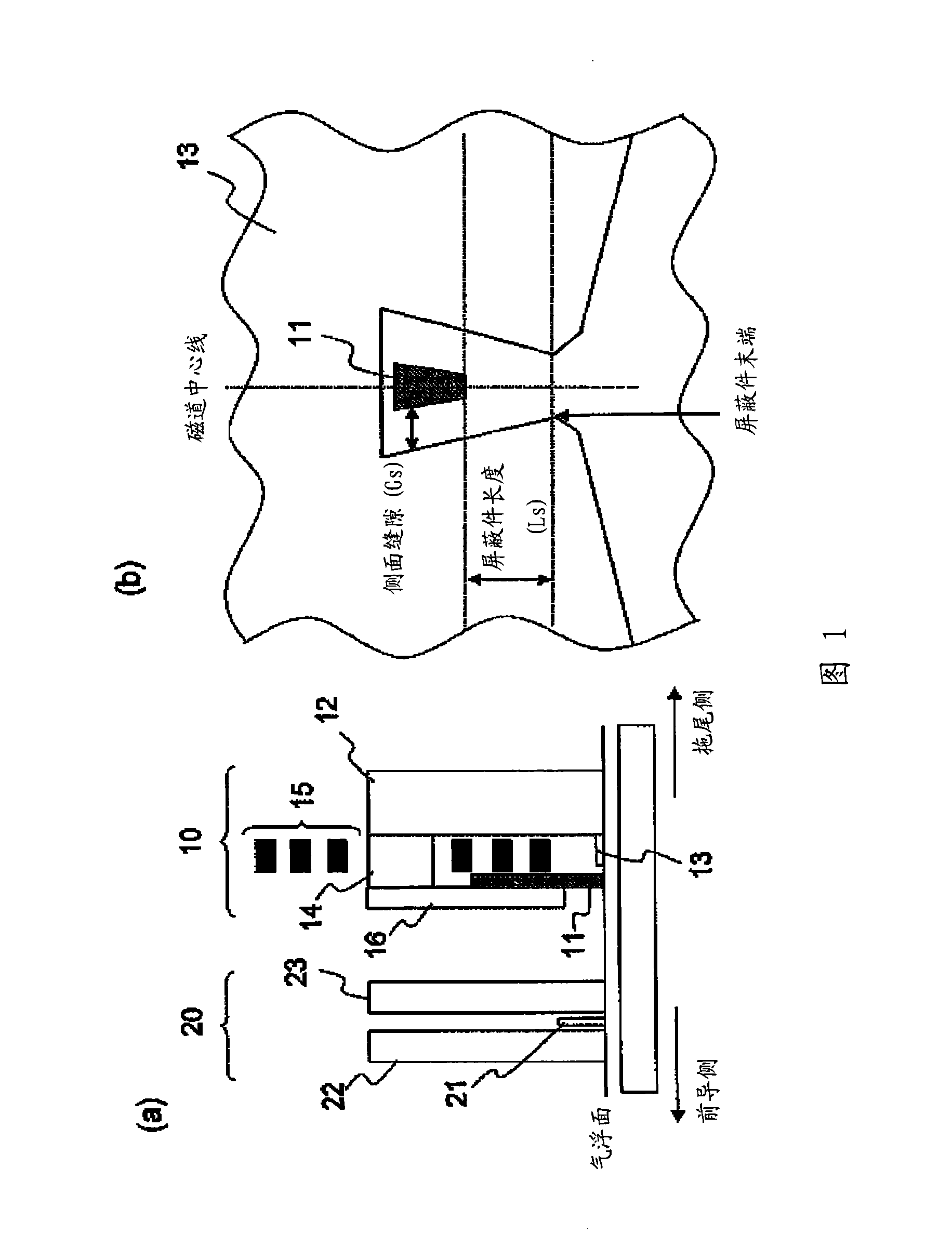

[0049] FIG. 1(a) shows a schematic cross-sectional view at the center line of the track, which illustrates an example of the magnetic head according to the present invention. The magnetic head is a recording / reproducing composite head that has a recording head 10 including a main pole 11 and an auxiliary pole 12, and a reproduction head 20 including a read element 21. For the reproduction head 20, a CIP-GMR element, a TMR element, or a CPP-GMR element, etc. is used, which is provided on a pair of magnetic components including a lower shield 22 on the leading side and an upper shield 23 on the trailing side. Between shields. The writing function part has a basic structure that includes a main pole 11 that performs writing to the disk, a position on the trailing side of the main pole, and a side of each side of the main pole in the cross-track direction. The shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com