Optical information recording medium and its manufacture method

A technology for recording media and optical information, applied in temperature recording method, optical recording carrier, recording/reproducing by optical method, etc., which can solve the problems of high cost and reduced corrosion resistance of light reflection layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] On the surface of a substrate made of injection-molded polycarbonate resin having a spiral groove (groove depth: 30nm, groove width: 150nm, track pitch: 340nm) with a thickness of 1.1mm, an outer diameter of 120mm, and an inner diameter of 15mm , in an Ar atmosphere, a light reflection layer made of aluminum (Al: purity 99.9% by mass or more) was formed by DC sputtering. The detailed conditions of sputtering are described in Table 1.

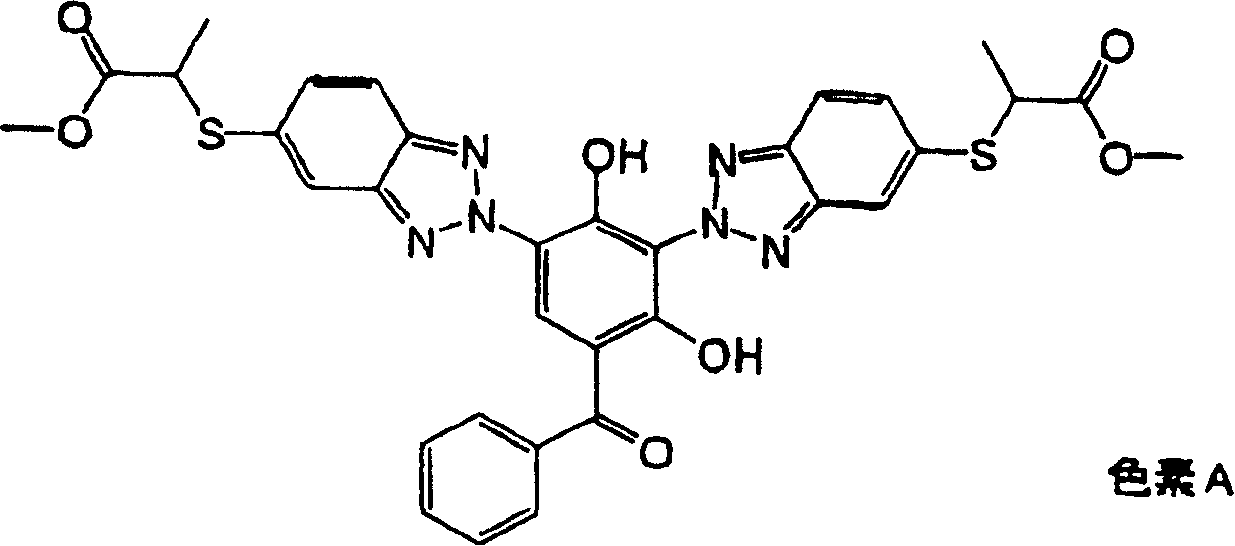

[0070] Then, 2 g of a dye represented by the following chemical formula was added to 100 ml of 2,2,3,3-tetrafluoropropanol and dissolved to prepare a dye coating solution. The pigment coating liquid was coated on the light reflection layer under the conditions of 23° C. and 50% RH by the spin coating method while changing the rotation speed from 300 rpm to 4000 rpm. Then, it was stored at 23° C. and 50% RH for 1 hour to form a recording layer (ingroove thickness: 100 nm, on groove thickness: 70 nm).

[0071] 【Chemical 1】

[0072]

...

Embodiment 2 to 5

[0086] Optical information recording media of Examples 2 to 5 were produced in the same manner as in Example 1 except that the conditions for forming the light reflection layer in Example 1 were changed as shown in Table 1.

[0087] The same test as in Example 1 was performed on the obtained optical information recording medium to evaluate recording characteristics. The results are shown in Table 1.

Embodiment 6 to 19

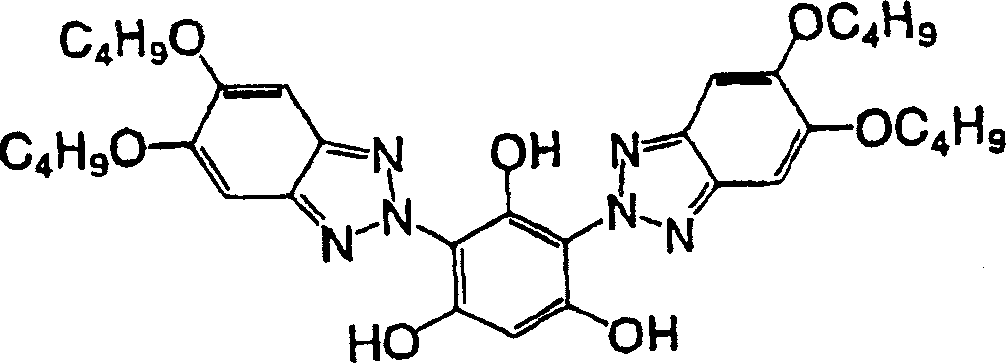

[0089] Under the conditions shown in Table 1 and an Ar atmosphere, DC sputtering was performed on a substrate made of an injection-molded polycarbonate resin (polycarbonate manufactured by Teijin Corporation; trade name panlaido AD5503) having a thickness of 1.1 mm. A light reflection layer made of aluminum or an aluminum alloy is formed on the surface of a spiral groove (groove depth: 40nm, groove width: 150nm, track pitch: 320nm) with an outer diameter of 120mm and an inner diameter of 15mm. In addition, in Example 7, the Ti content in the aluminum alloy (Al—Ti) was 2 at%.

[0090] Then, 2 g of an organic substance represented by the following chemical formula was mixed with 100 ml of methyl lactate, and dissolved by ultrasonic treatment for 2 hours to prepare a pigment coating liquid. The pigment coating solution was coated on the light reflection layer under the conditions of 23° C. and 50% RH by the spin coating method while changing the rotation speed from 300 to 4000 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com