Thin-film magnetic head and method of manufacturing same, head gimbal assembly, and hard disk drive

A technology of a thin film magnetic head and a manufacturing method, which is applied to a magnetic head using a thin film, a magnetic recording head, a magnetic flux sensitive magnetic head, etc., can solve the problem that it is difficult to reduce the deviation of the magnetic pole width, and it is difficult to form a photoresist with high precision. borders etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

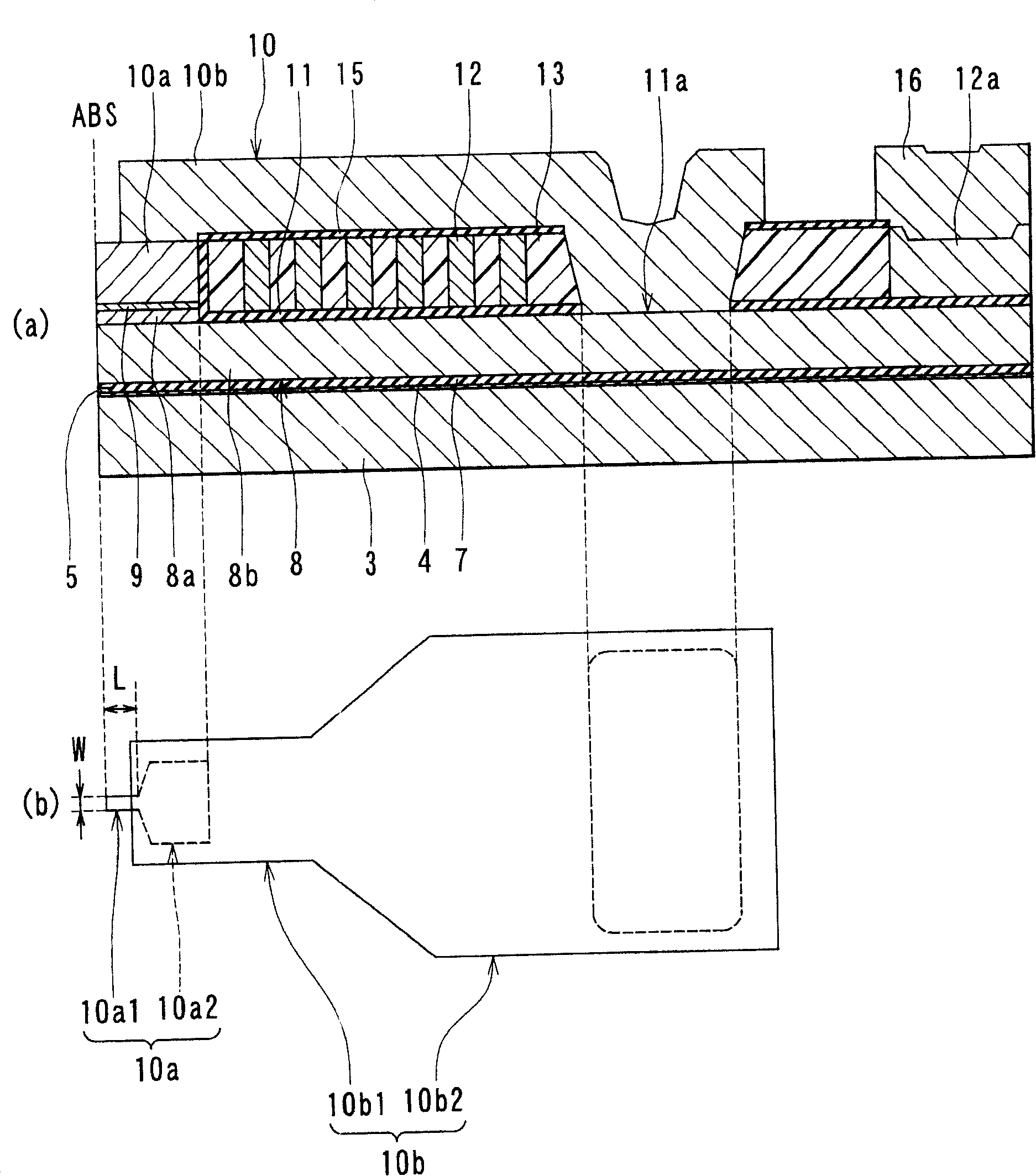

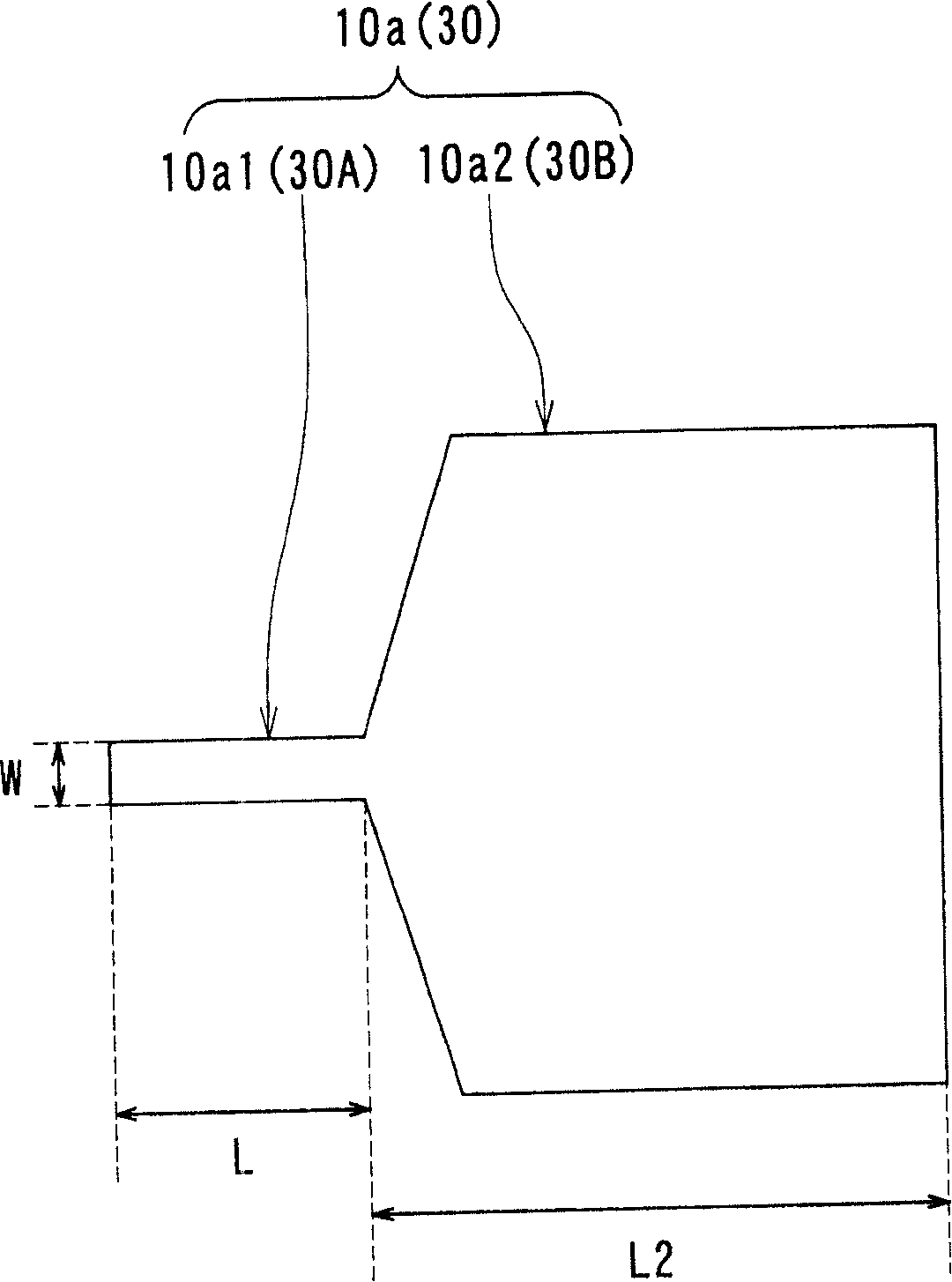

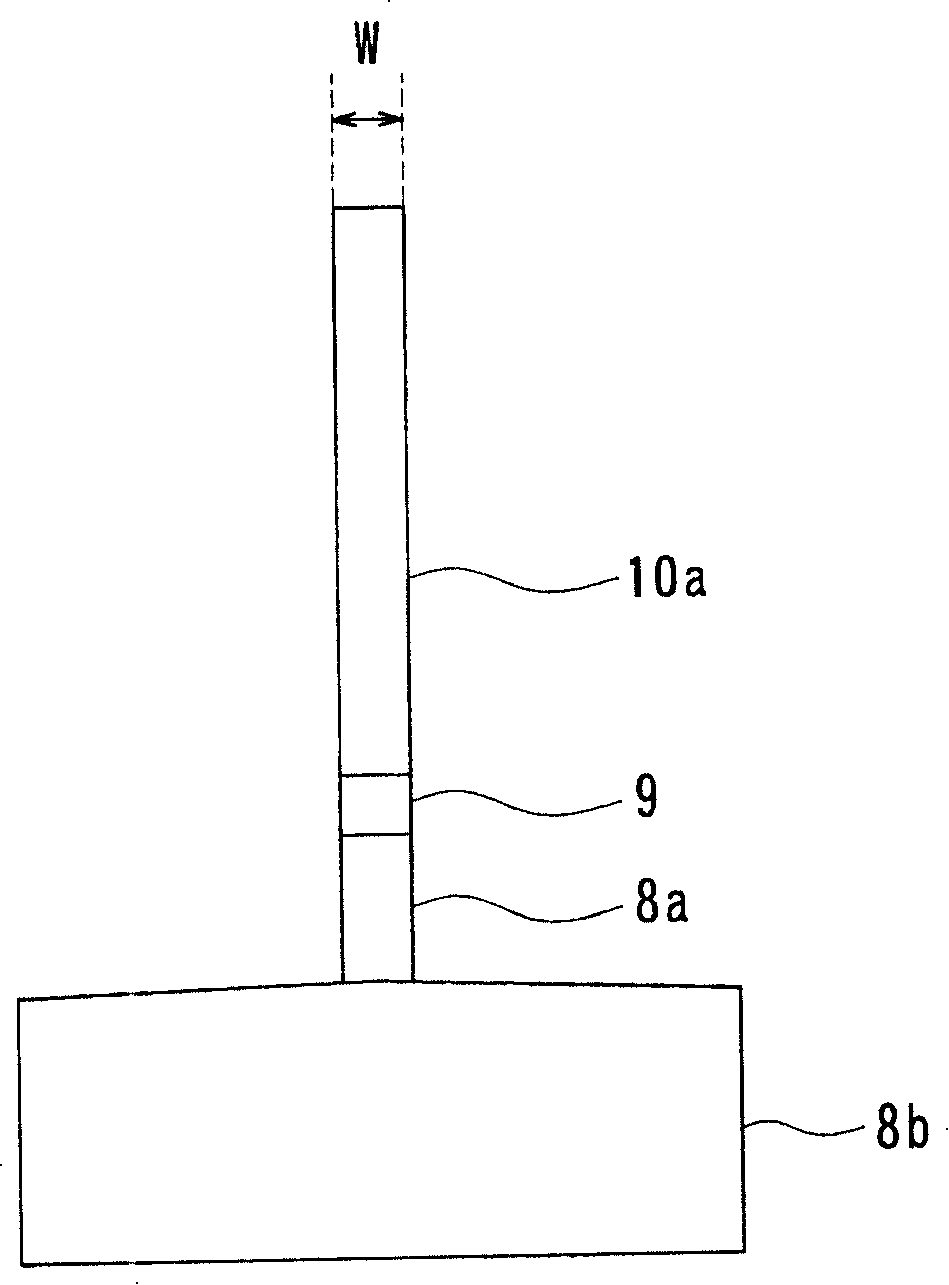

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. First, refer to figure 1 and Figure 12 The structure of a thin film magnetic head according to an embodiment of the present invention will be described. figure 1 It is an explanatory diagram showing main parts of a thin-film magnetic head according to an embodiment of the present invention. exist figure 1 Among them, (a) shows a cross section perpendicular to the medium-facing surface and the substrate surface of the main part of the thin-film magnetic head. In addition, (b) shows the planar shape of the upper magnetic pole layer of the thin-film magnetic head. Figure 12 A cross section perpendicular to the medium-facing surface and the substrate surface of the thin-film magnetic head is shown.

[0041] The thin-film magnetic head of this embodiment is equipped with aluminum oxide·titanium carbide (Al 2 o 3 A substrate 1 made of a ceramic material such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com