Polishing pad and glass substrate manufacturing method using said polishing pad

A technology for a glass substrate and a manufacturing method, applied in the field of polishing pads, can solve the problems of decreased processing rate in the mirror polishing process, insufficient cleaning of the bottom, and inability to polish the glass substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

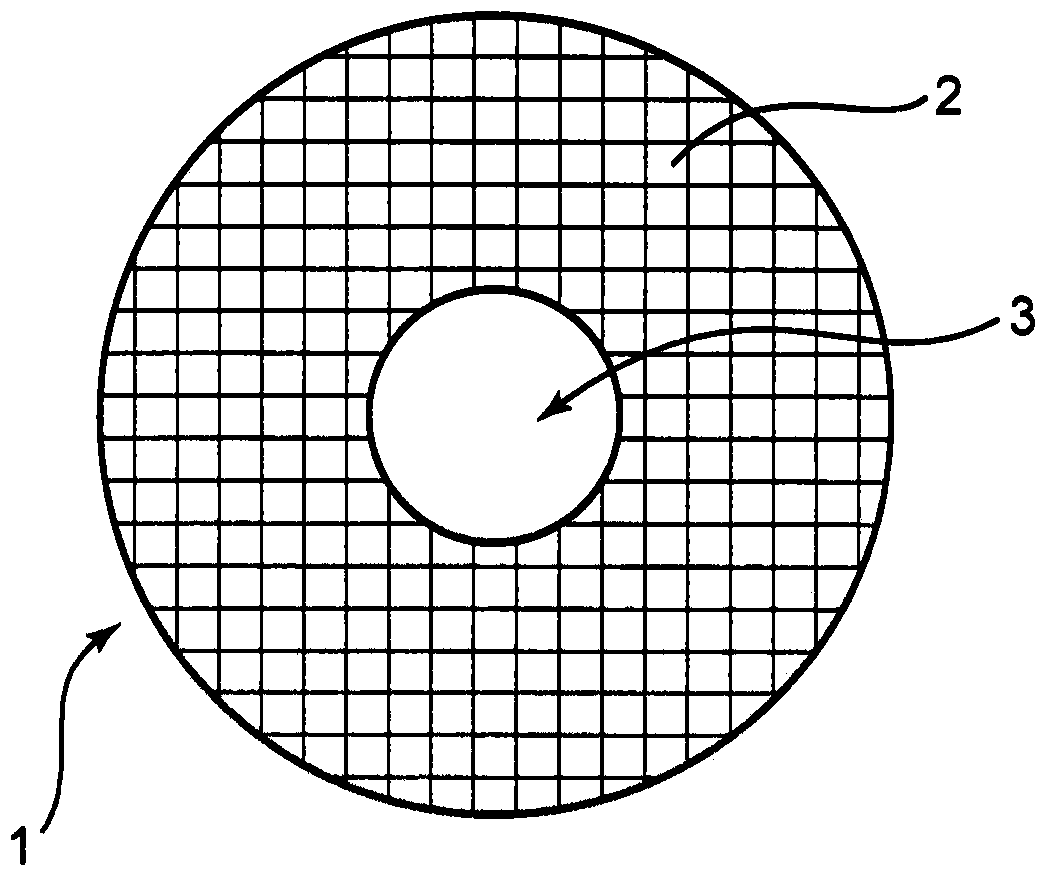

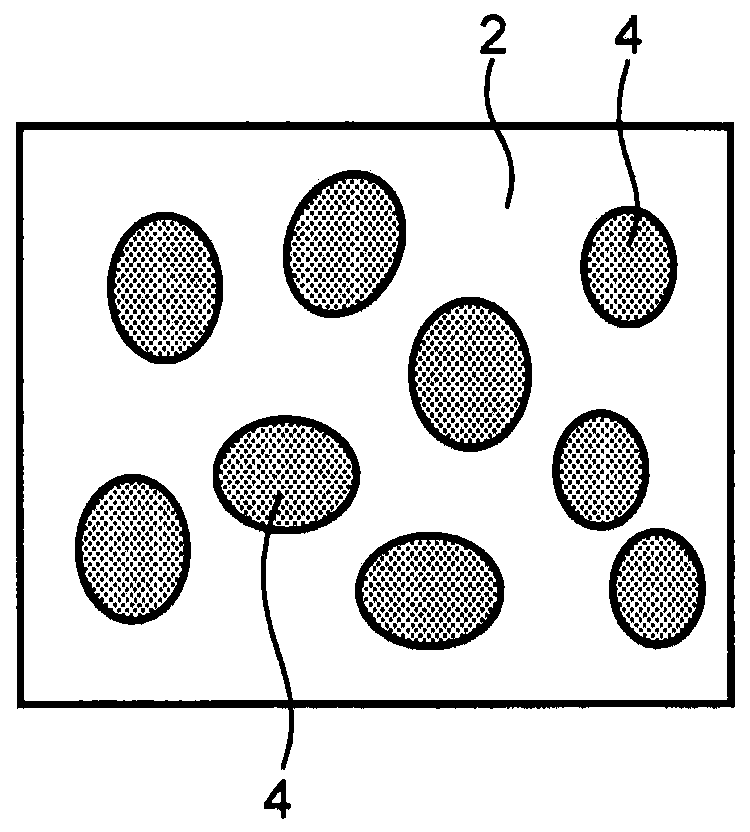

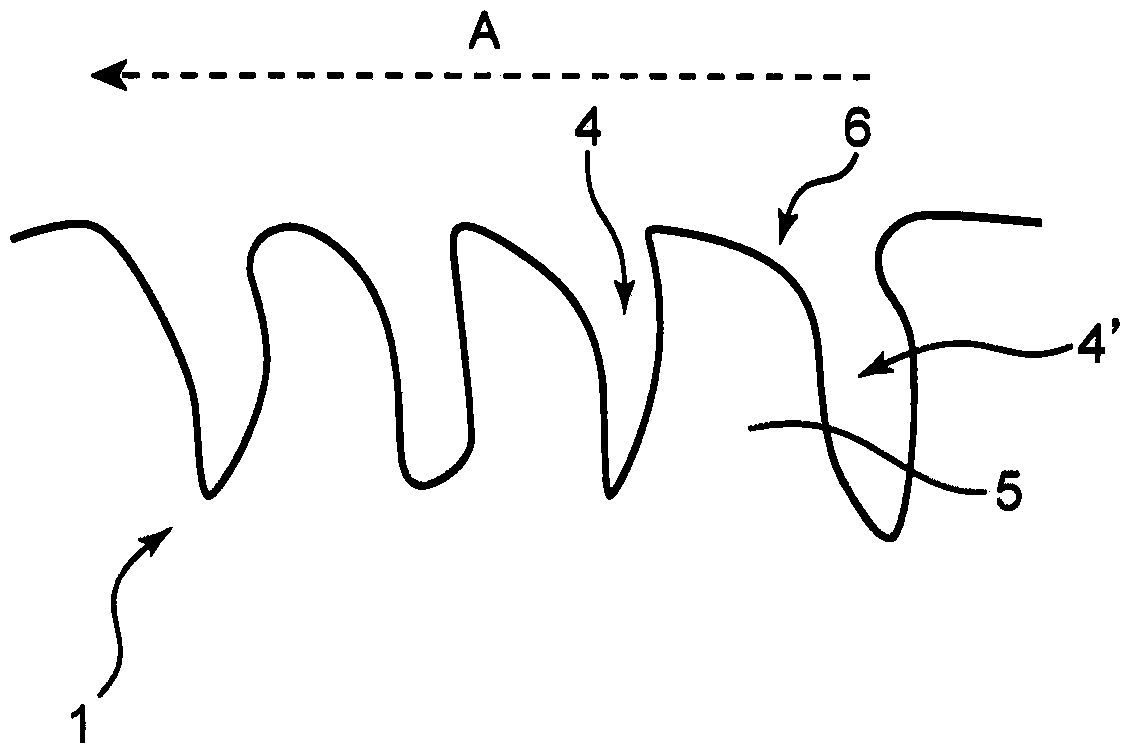

[0079] For polishing flat plates (outer diameter approx. Inner diameter approx. A suede pad (manufactured by Filwel, NP225) was pasted on a doughnut-shaped donut shape, and a dummy workpiece was processed for 10 hours. In the processing of the dummy workpiece, the load value was decreased from 12 kPa to 5 kPa over time. The rotation speed of the carrier relative to the polishing plate was about 2 rpm, and the revolution speed of the carrier relative to the flat plate was about 10 rpm.

[0080] After the processing of the dummy workpiece is completed, the polishing pad is peeled off from the double-sided polishing machine, and the polishing pads at the positions corresponding to the radius of 240mm, 400mm, and 540mm of the polishing plate are respectively intercepted, and the confocal microscope (Keyence ( A laser microscope, VK-9700 manufactured by KEYENCE) was used for three-dimensional measurement of a 300 μm square. Figure 8 The above intercept positions are shown in ...

Embodiment 2

[0099] Except having set the processing time of a dummy workpiece into 5 hours, the buff pad was produced by the method similar to Example 1, and the glass substrate was produced using the produced buff pad.

Embodiment 3

[0101] The arrangement of the dummy workpiece was changed, and the center part of the flat plate was set as the target of dummy workpiece processing, and the polishing pad was produced by the method similar to Example 2, and the glass substrate was produced using the produced polishing pad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com