Cartridge for the preparation of beverages and method of manufacturing the same

A storage box and beverage technology, applied in beverage preparation devices, applications, household appliances, etc., can solve problems such as the difficulty of forming small holes, and achieve the effect of optimized manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

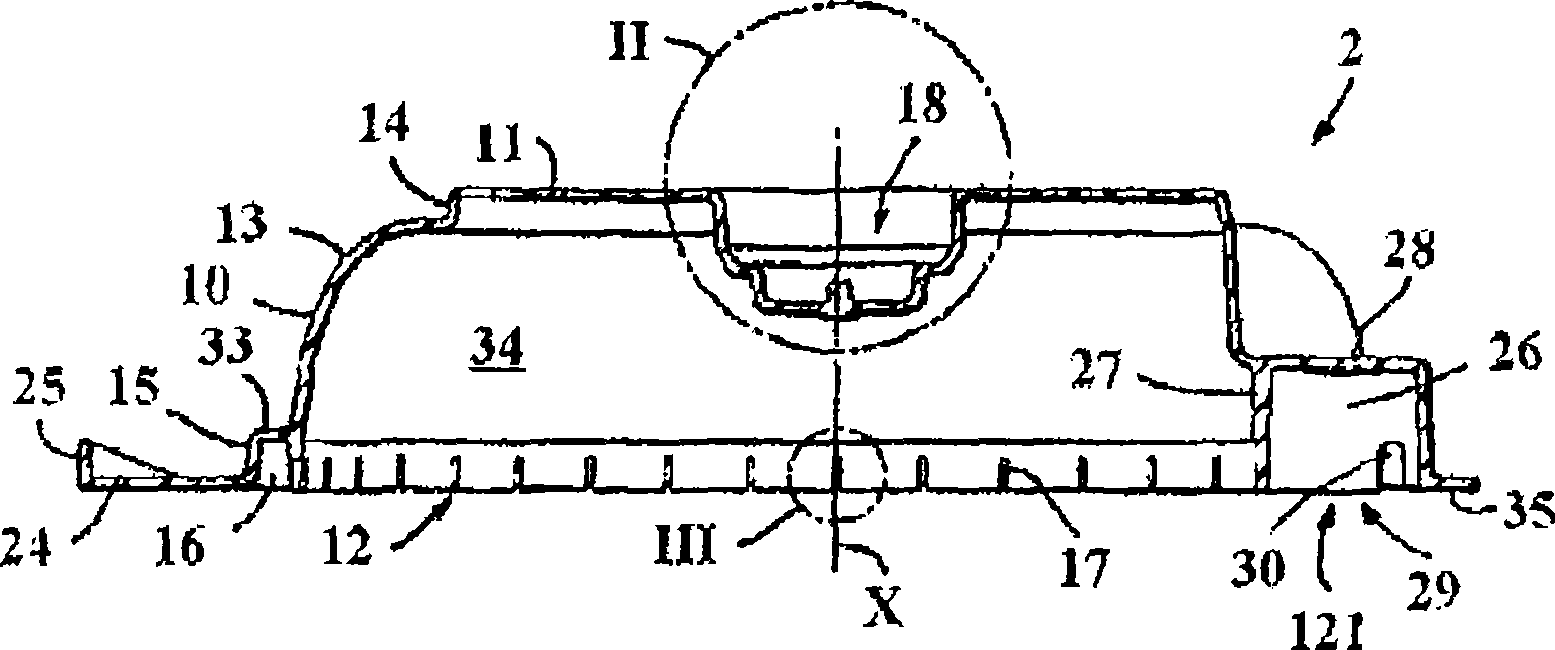

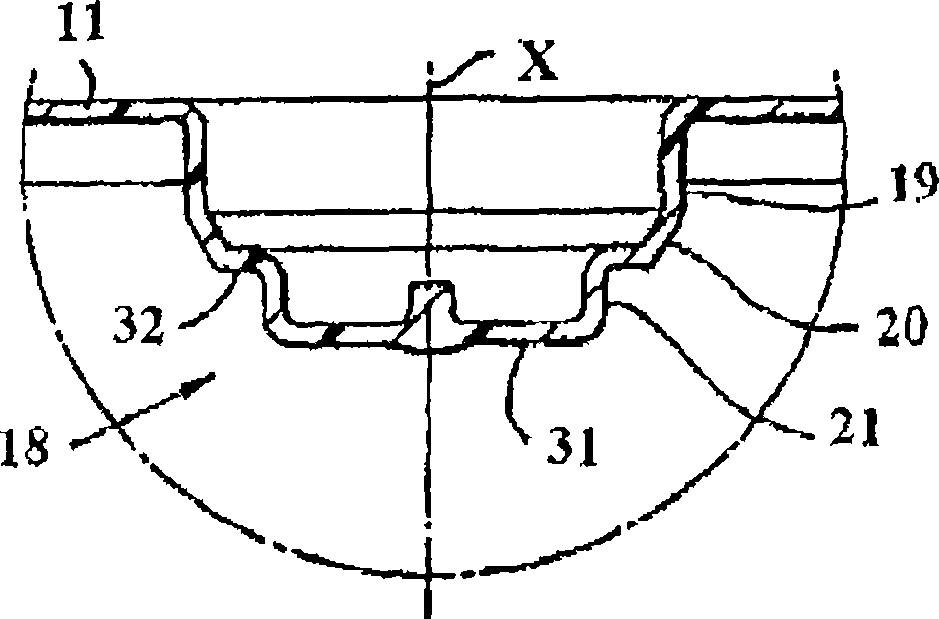

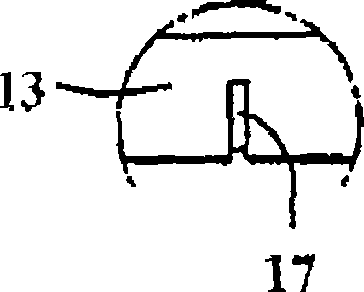

[0123] like Figure 11 As shown, the cartridge 1 of the present invention generally comprises an outer part 2 , an inner part 3 and a laminate 5 . The outer part 2, the inner part 3 and the laminate 5 are assembled together to form a cartridge 1 having an interior 120 for containing one or more beverage ingredients, an inlet 121, an outlet 122, and connecting the inlet 121 to the outlet 122 And through the beverage flow path of the interior 120 . The inlet 121 and outlet 122 are initially sealed by the laminate 5 and are opened by piercing or cutting the laminate 5 in use. The beverage flow path is defined by the spatial interrelationship between the outer part 2, the inner part 3 and the laminate 5, as described below. Other components may optionally be included in the cartridge 1, such as a filter 4, as described further below.

[0124] exist Figures 1 to 11 Shown is a first version of the cartridge 1 that will introduce the use described for the background art. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com