Recording apparatus

一种记录装置、驱动力的技术,应用在记录装置领域,能够解决成本增高等问题,达到减少配设件数、实现装置的简化和小型化、降低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

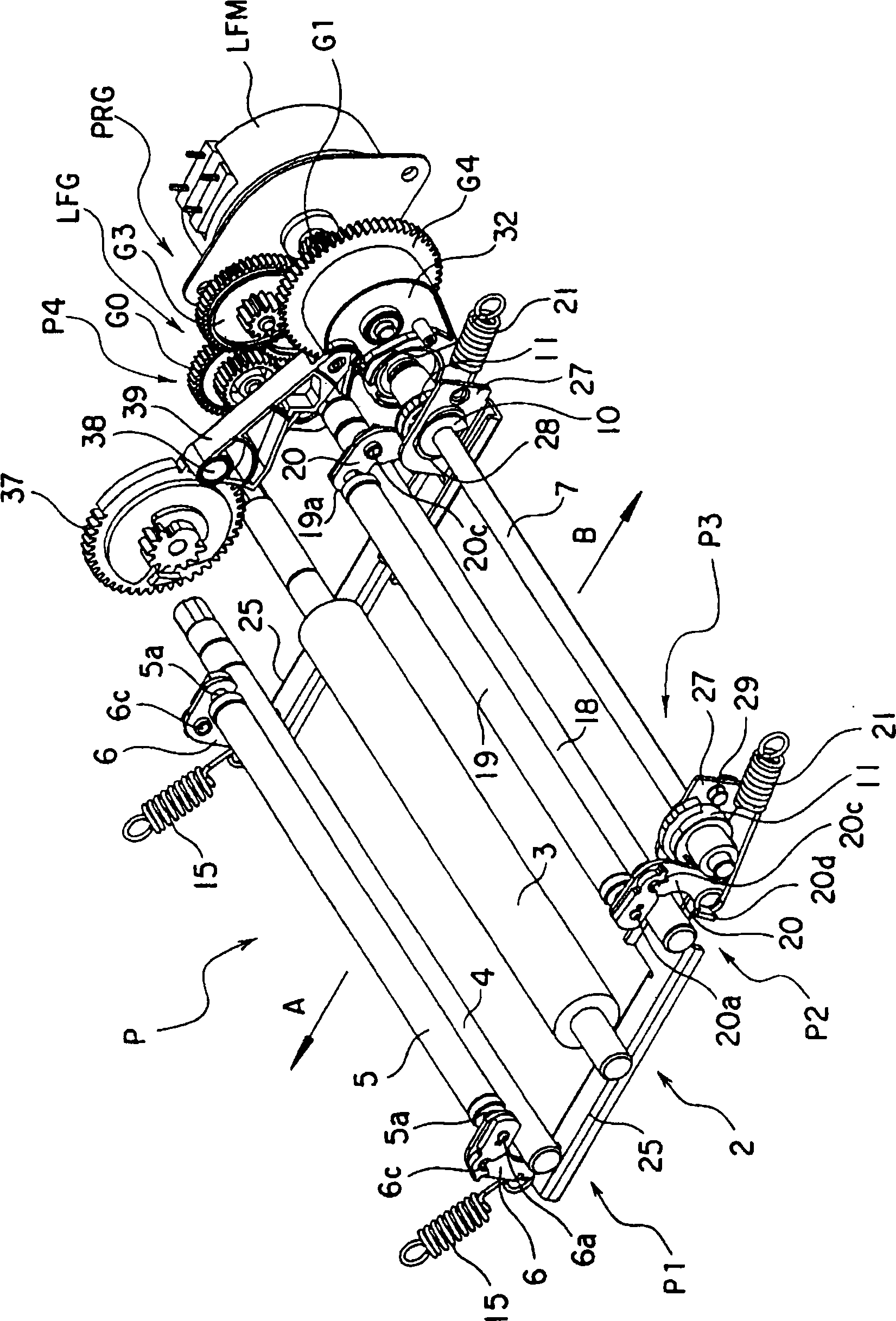

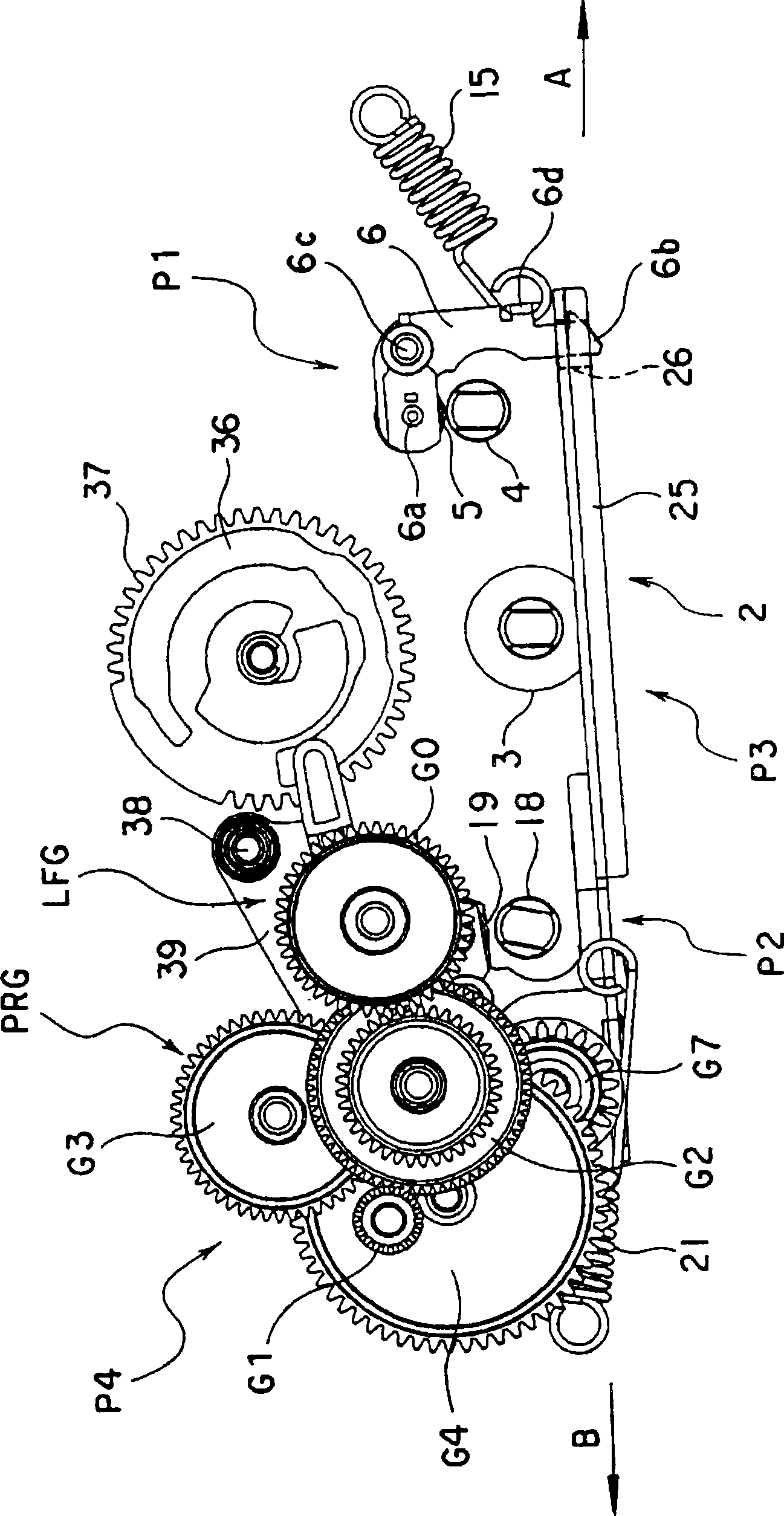

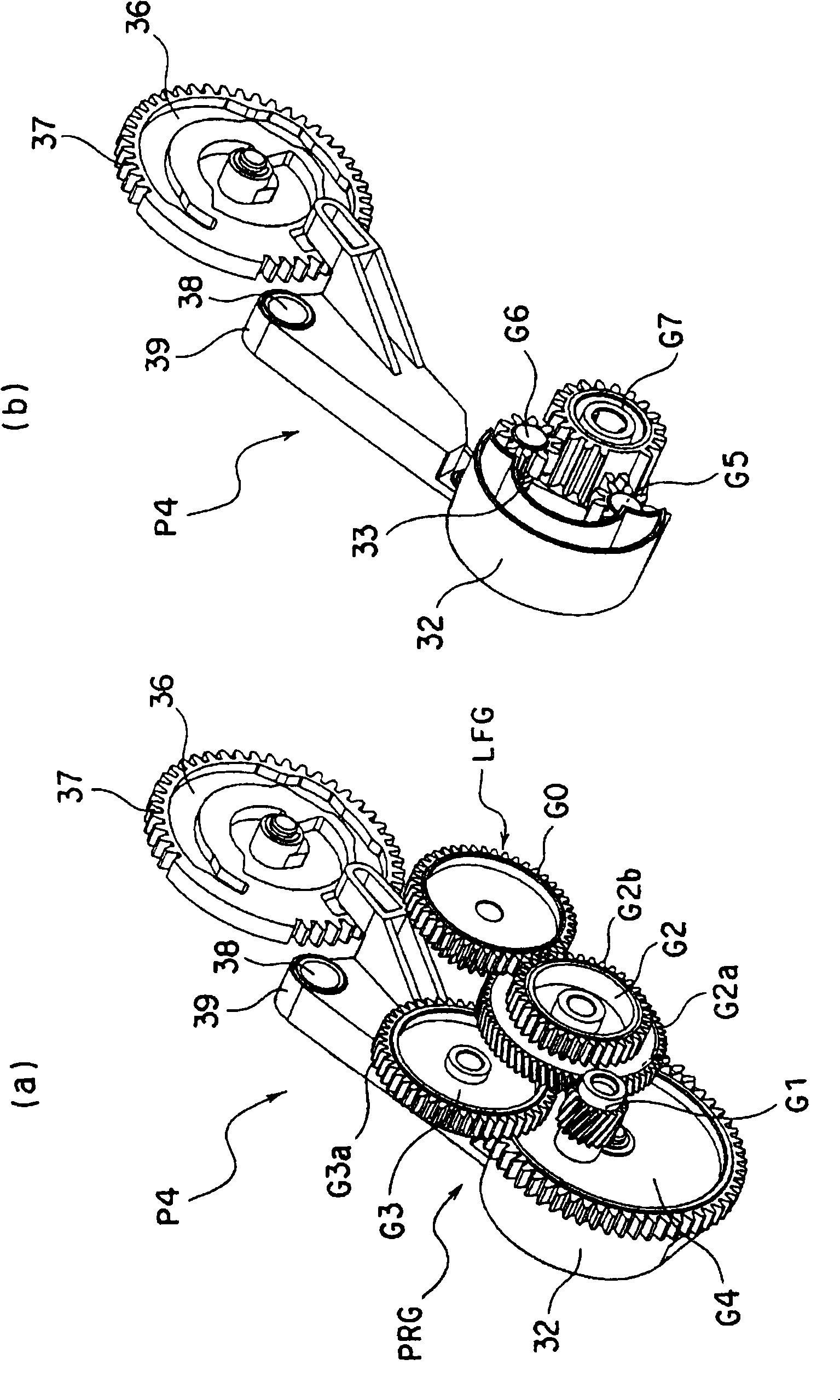

[0030] The following will be based on Figure 1 to Figure 16 Embodiments of the recording device of the present invention will be described.

[0031] Such as figure 1 As shown, the recording device P of this embodiment is equipped with a printing mechanism 2 on the middle part of the recording paper transport path. 2 The desired image can be printed on recording paper (not shown in the drawing) such as photographic paper.

[0032] The above-mentioned printing mechanism 2 includes a cylindrical platen roller 3 and a thermal head (not shown in the drawings). Between the frames, the platen roller 3 is rotatable by the driving force for conveying the paper transmitted by the LF motor LFM, and the thermal head can contact and separate from the platen roller 3 by the driving force of the UD motor (not shown).

[0033] Moreover, the first paper feeding mechanism P1 is arranged on the downstream side of the left side of the platen roller 3 in the drawing in the direction of the arrow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com