Sealing and guiding device for a piston of a piston pump

A technology for guiding devices and piston pumps, which is applied in the direction of pumps, multi-cylinder pumps, liquid variable displacement machines, etc., can solve the problems that the sealing performance of piston pumps cannot be guaranteed, and achieve automatic calibration, prevent radial frequency, and high use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

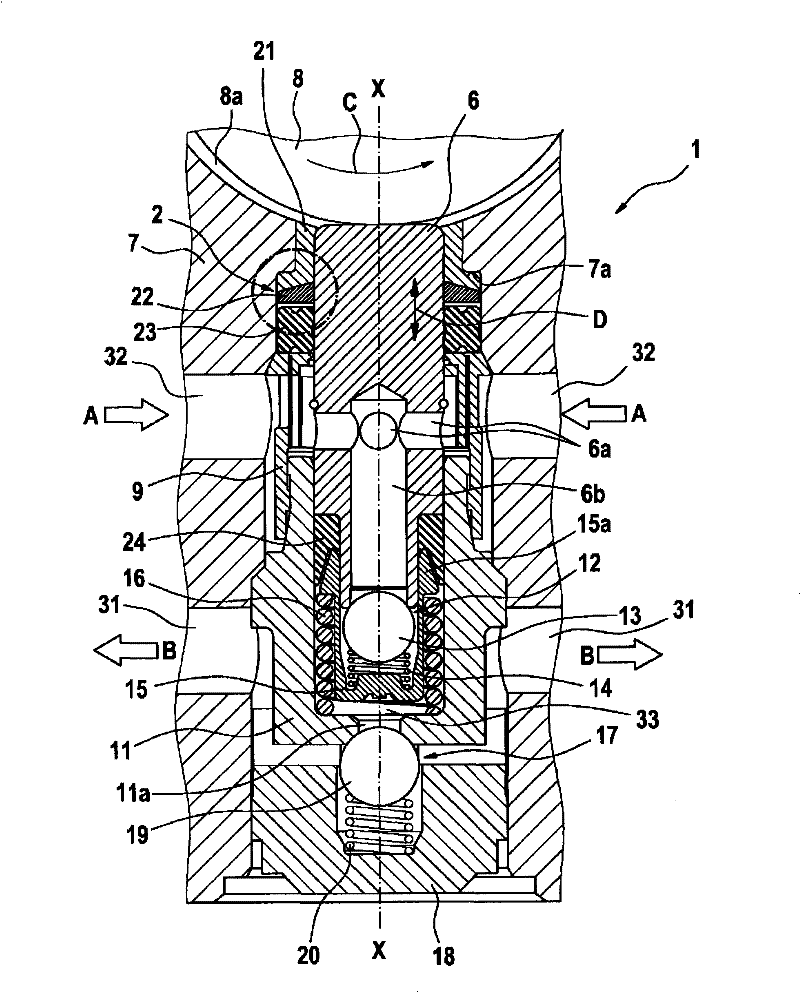

[0021] Such as figure 1 As shown, the piston pump 1 comprises a piston 6 which is driven via an eccentric 8 . The eccentric 8 rotates in the direction of the arrow C and is in contact with the end of the piston 6 . This causes the piston 6 to reciprocate in the direction of the double arrow D along the axial direction X-X of the piston pump 1 . Four (or two) transverse bores 6a are provided in the piston 6, through which the fluid from the supply line 32 flows through the filter 9 into the longitudinal bores 9b. This is indicated by arrow A.

[0022] The piston pump 1 also comprises an inlet valve 12 , an outlet valve 17 and a pressure chamber 33 arranged between the inlet valve 12 and the outlet valve 17 . The pressure chamber 33 is arranged inside the cylinder part 11 , which has a substantially bowl-shaped shape. A filter 9 is attached to the end of the cylinder part 11 directed toward the eccentric 8 . An inlet valve 12 is arranged on the end of the piston 6 on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com