All-steel radial tire with zero degree undertread structure

A radial tire and belt technology, applied in the field of all-steel radial tire 0-degree belt structure adjustment, can solve the problems of reduced tire wear performance and sacrifice of tire service life, so as to reduce strain energy and reduce tire shoulder cavity disease. The effect of improving tire durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

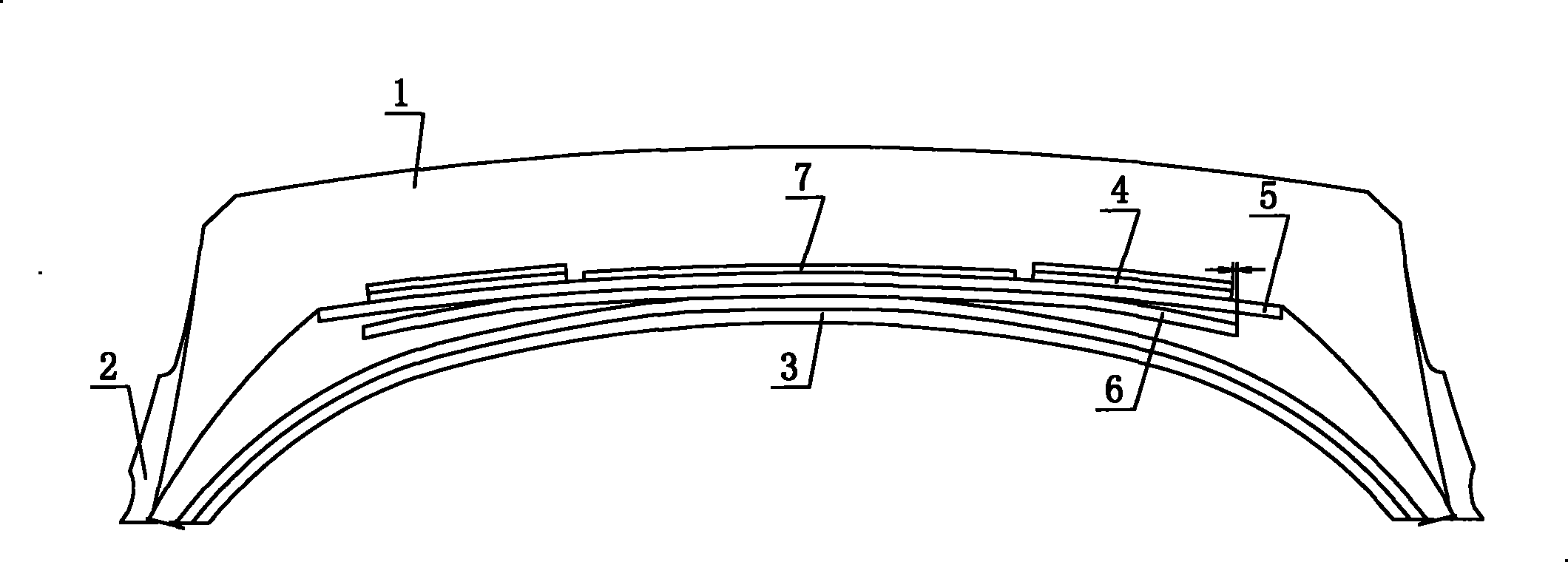

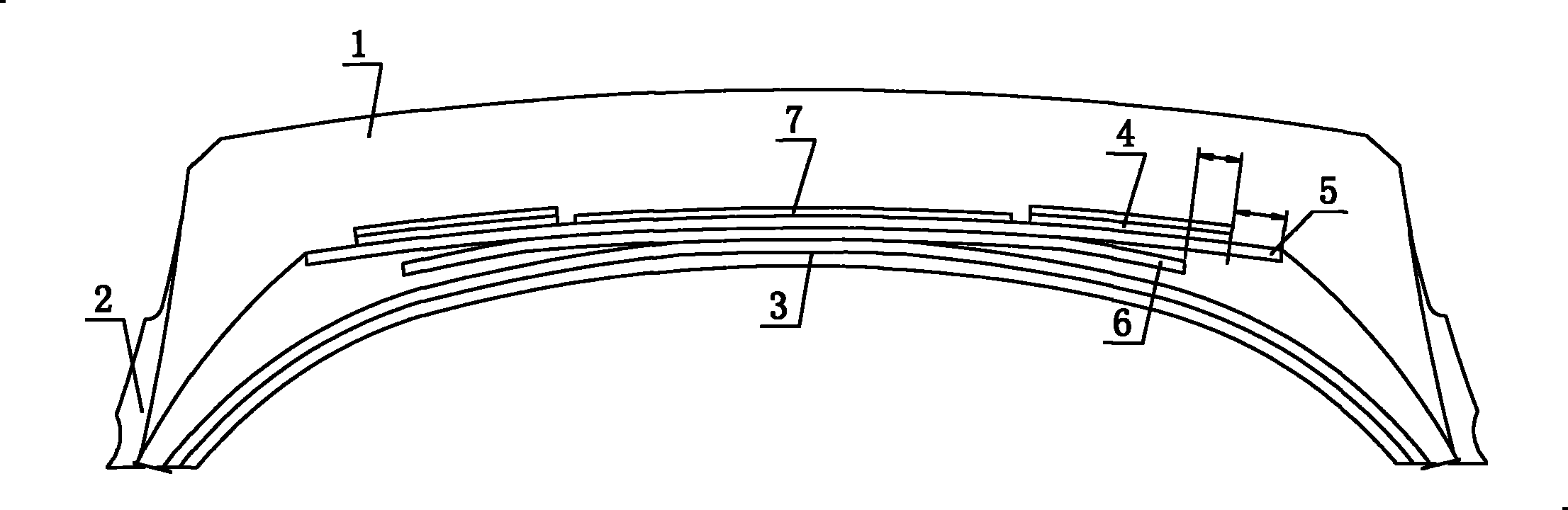

[0016] Such as figure 2 The all-steel radial tire with 0-degree belt layer 4 structure shown, the tire includes a table portion 1, a sidewall portion 2, a bead portion and a carcass layer 3, and the outer side of the carcass layer 3 is 1# belt layer 6 in sequence , 2# belt layer 5 and 0 degree belt layer 4, the middle part of 0 degree belt layer 4 is 3# belt layer 7.

[0017] Belt cutting width adjustment: 1# belt layer 6 width is 165mm, 1# belt layer 6 edge wrapping film is adjusted to 30mm*1.0mm; 2# belt layer 5 width is 200mm, edge wrapping rubber width is adjusted to 240mm, The isolation film is adjusted to 30mm*1.5mm; the width of 3# belt layer 7 is 100mm.

[0018] The 0 degree belt layer 4 is wider than the 1# belt layer 6, and the level difference between the 1# belt layer 6 and the 0 degree belt layer 4 is 7.5 mm. 2# belt layer 5 is wider than 0 degree belt layer 4, and the difference between 2# belt layer 5 and 0 degree belt layer 4 is 10mm.

[0019] The rest will...

Embodiment 2

[0021] Such as figure 2 The all-steel radial tire shown has a 0-degree belt 4 structure. The tire includes a table portion, a sidewall portion, a bead portion, and a carcass layer. The outer sides of the carcass layer are 1# belt layer 6 and 2# belt Belt layer 5 and 0 degree belt layer 4, wherein: 0 degree belt layer 4 is wider than 1# belt layer 6, and the level difference between 1# belt layer 6 and 0 degree belt layer 4 is 6.5mm. 2# belt layer 5 is wider than 0 degree belt layer 4, and the difference between 2# belt layer 5 and 0 degree belt layer 4 is 11mm. Other technical characteristics are as shown in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com