Thermal-insulation electric heating kettle

An electric kettle, heating and heat preservation technology, applied in the direction of electric heating devices, electrical components, heating devices, etc., can solve the problems of large volume, increased production cost, complex structure, etc., and achieve high heat utilization rate, low cost, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

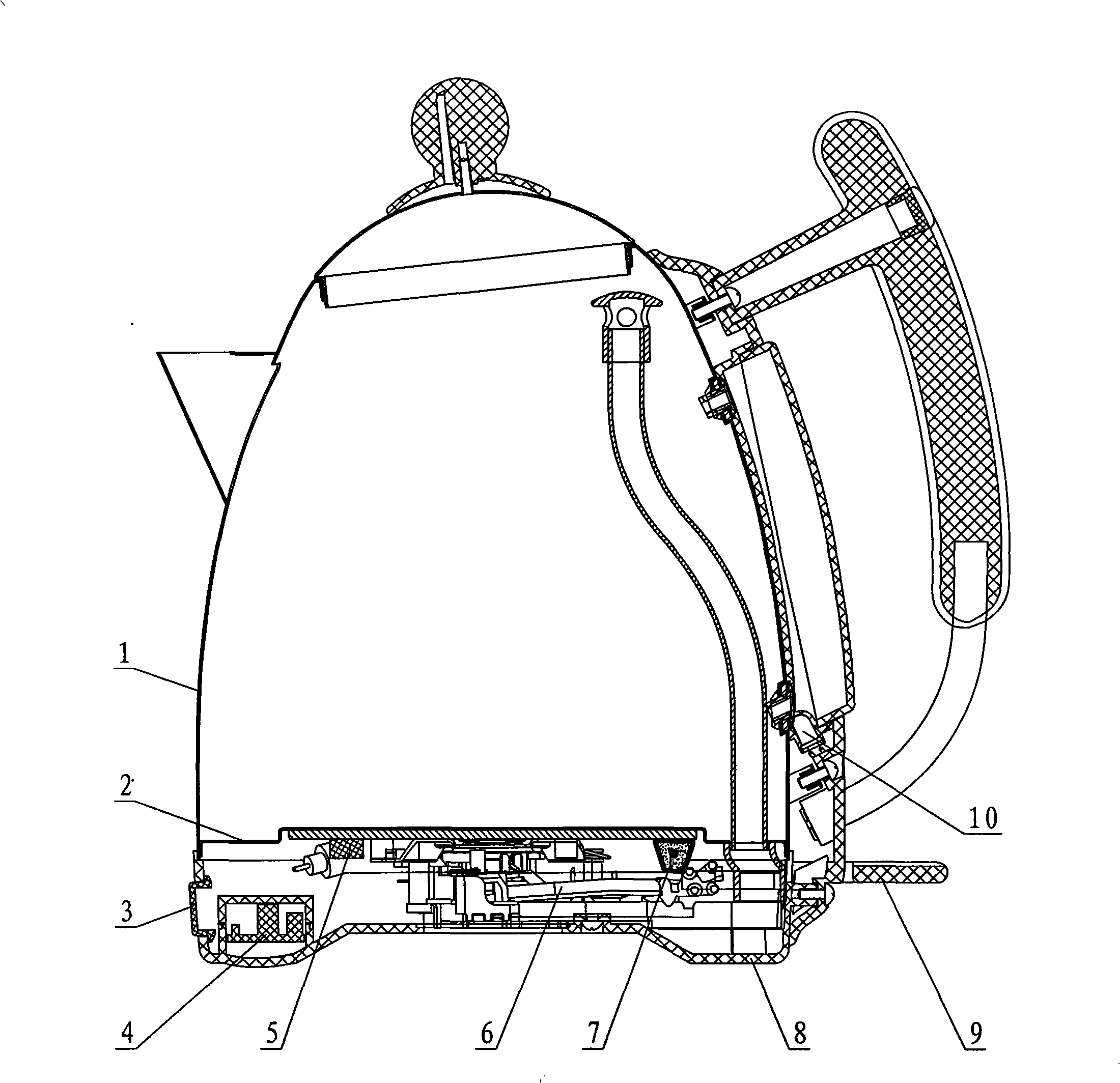

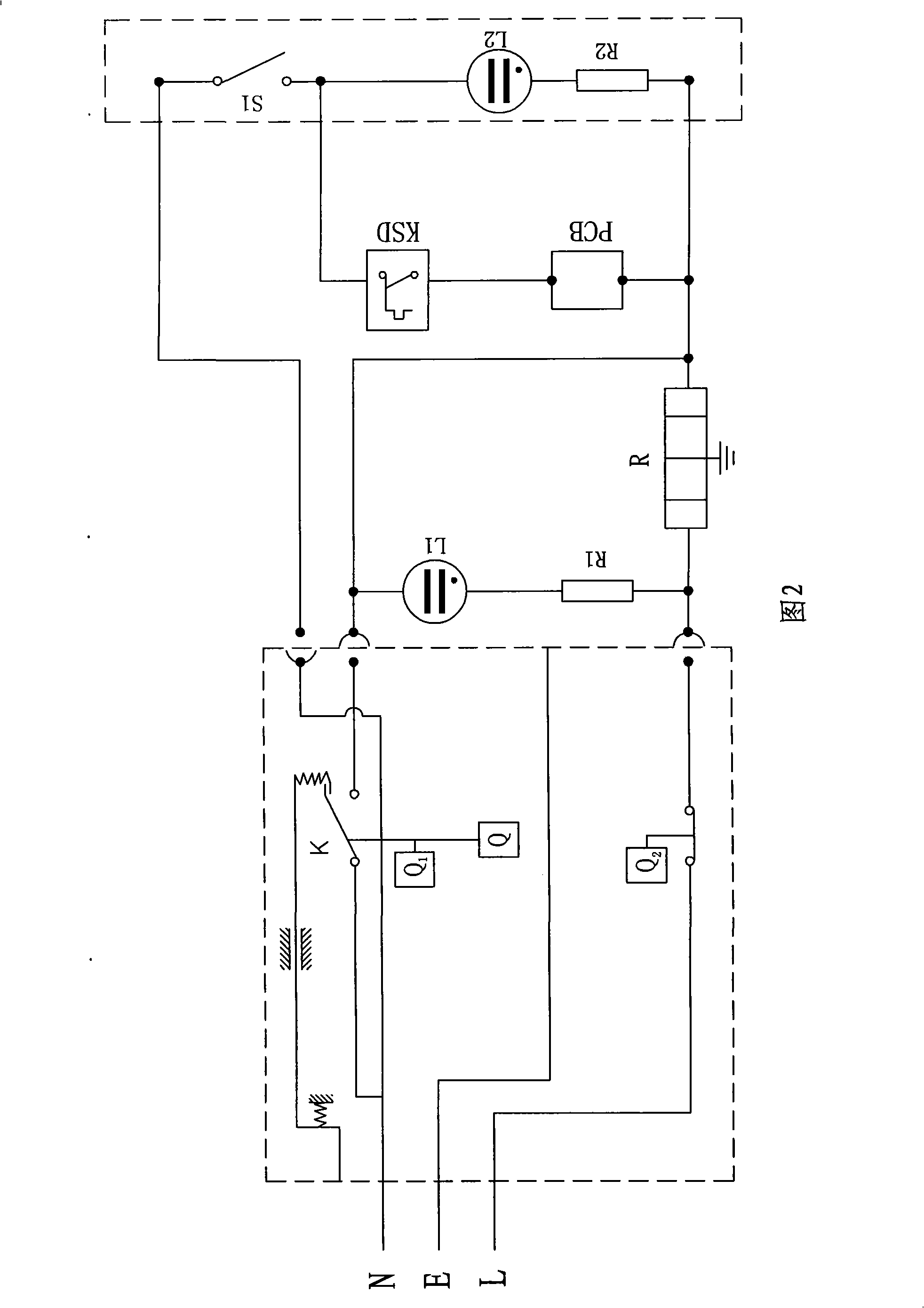

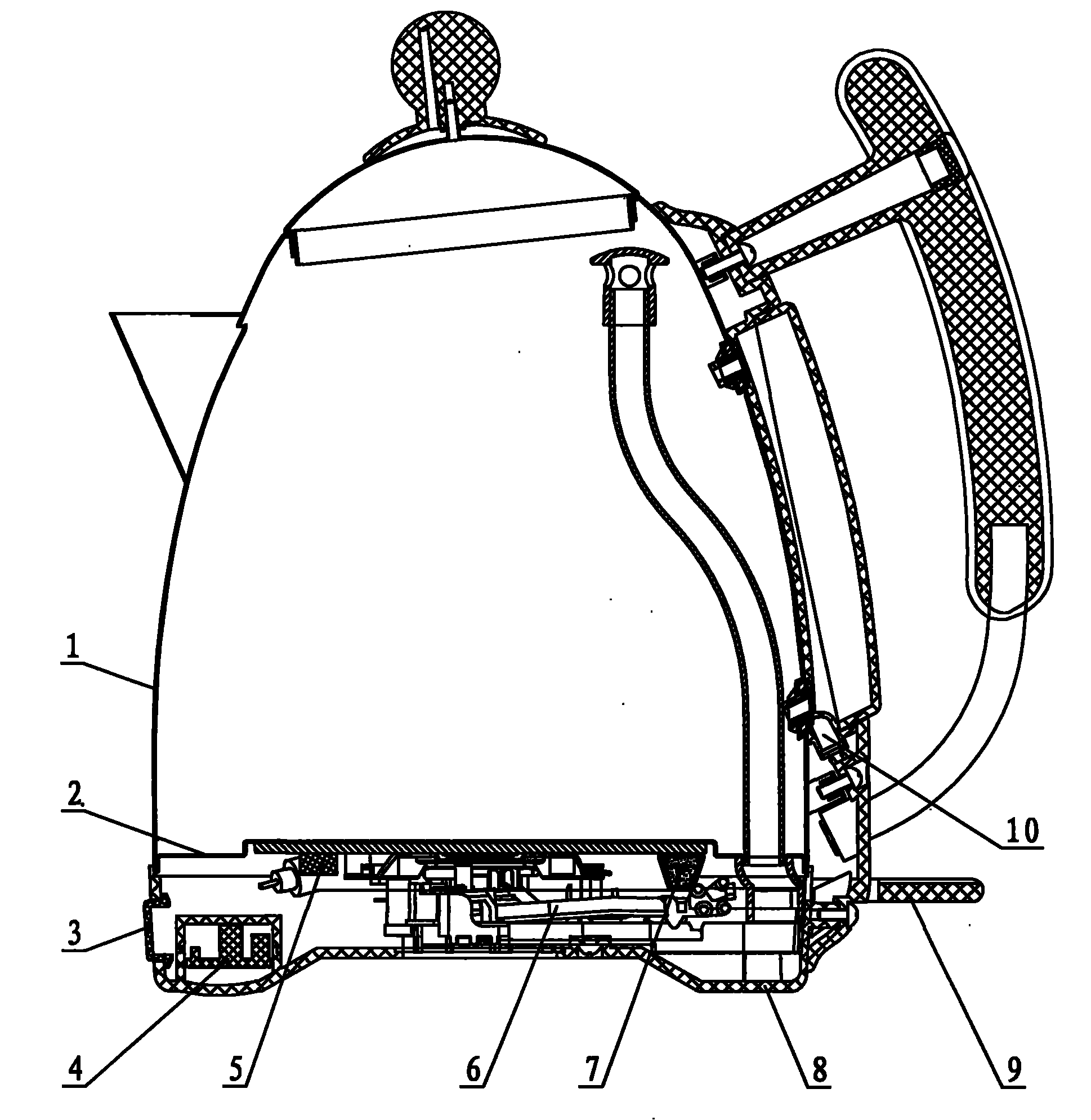

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] see figure 1 , this thermal insulation electric kettle includes a kettle body 1, a heating tube 7, a heating and boiling water circuit and a heating and insulation circuit, and the heating tube is connected in series in the heating and boiling water circuit and the heating and insulation circuit simultaneously. Heating insulation circuit, heating tube 7 and heating and boiling water circuit are packaged in the bottom of kettle body 1 by pot bottom cover 8, heating tube top surface is provided with heating disc 2, and heating disc is sealed with the bottom of kettle body. The heating and heat preservation circuit includes a jump-type thermostat 5 connected in series and a PCB board 4 for controlling the power of the heating tube, and the jump-type temperature controller is closely arranged on the heating plate. The heat preservation switch button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com