Method for cleaning and treating lamp glass tubes comprises washing the glass tubes with an aqueous washing medium at a specified ph and temperature

A technology of glass lamp tubes and fluorescent lamps, which is applied in the field of fluorescent lamps for background lighting, and can solve the problems that the lamp tubes cannot meet the purpose of use and the glass has poor chemical corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] SiO 2 66

[0126] Al 2 o 3 2.5

[0127] B 2 o3 18

[0128] Li 2 O 0.5

[0129] Na 2 O 0.5

[0130] K 2 O 7.5

[0131] MgO

[0132] CaO

[0133] SrO

[0134] BaO

[0135] ZnO 0.5

[0136] ZrO 2

[0137] As 2 o 3

[0138] Sb 2 o 3 0.5

[0139] Fe 2 o 3

[0140] TiO 2 4

[0141] Total 100

[0142] The geometric dimensions of the glass tube are as follows:

[0143] Outer diameter: 3.4mm

[0144] Inner diameter: 2.4mm

[0145] Wall Thickness: 0.5mm and

[0146] Glass tube length: 500mm.

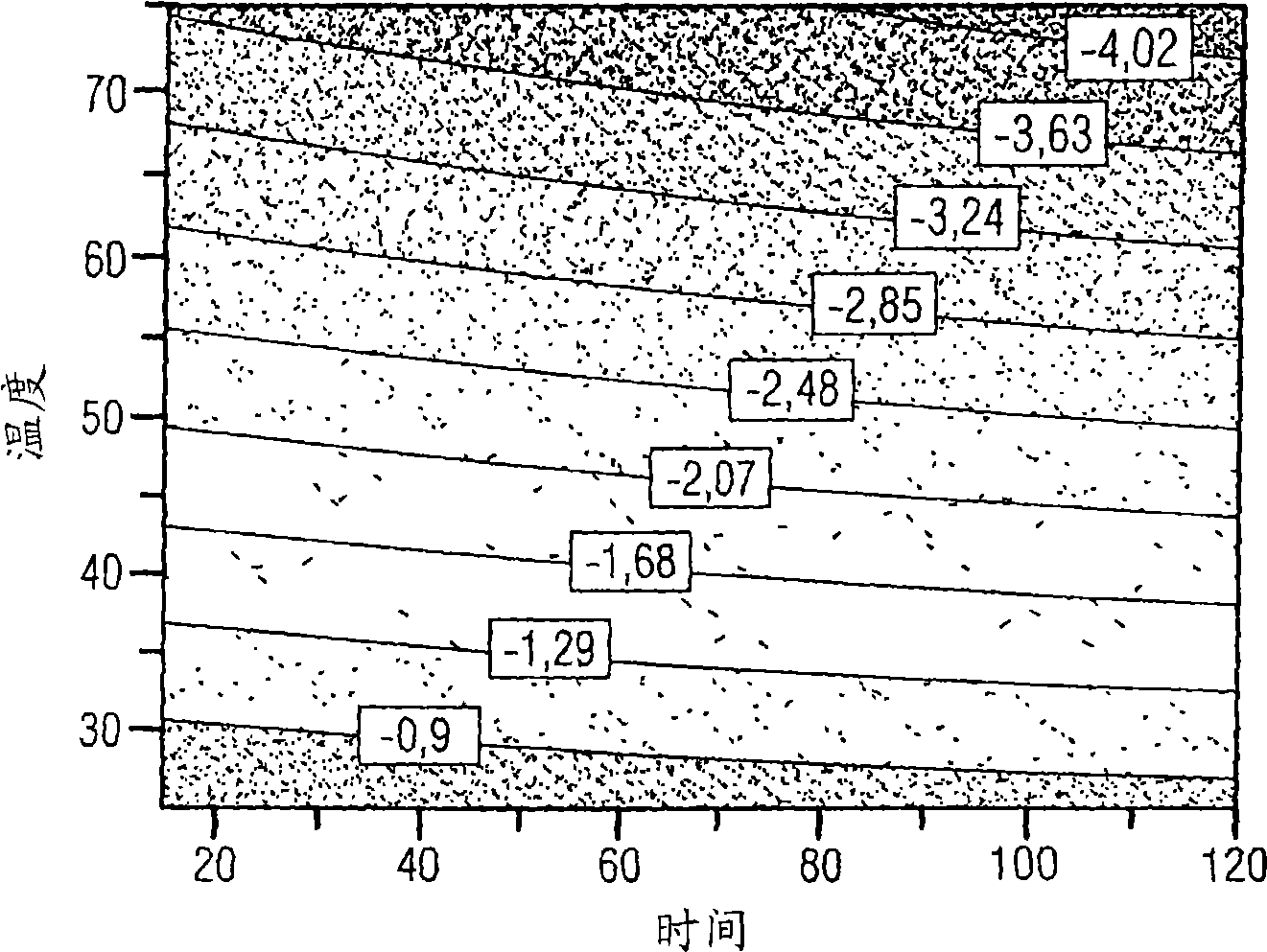

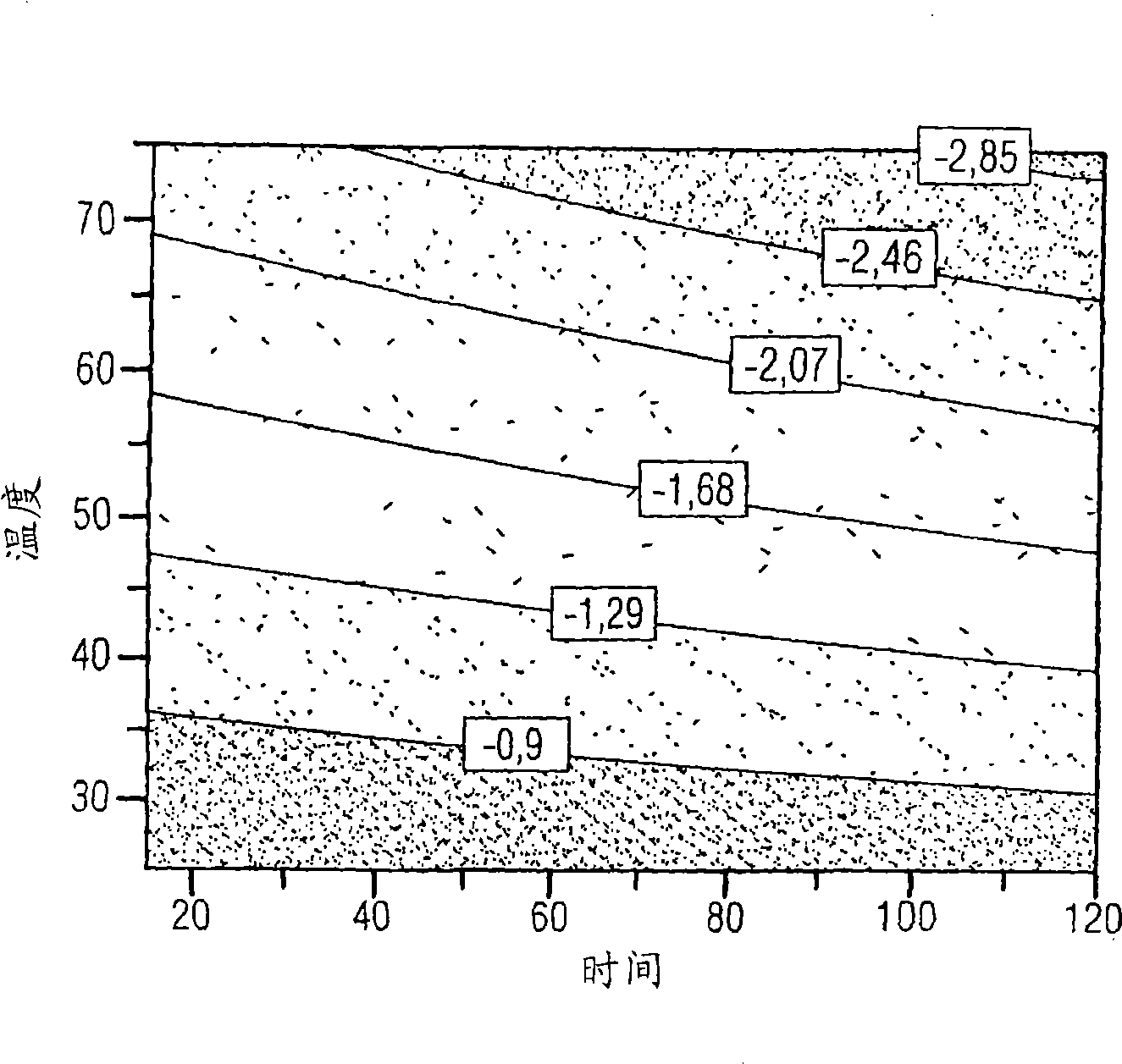

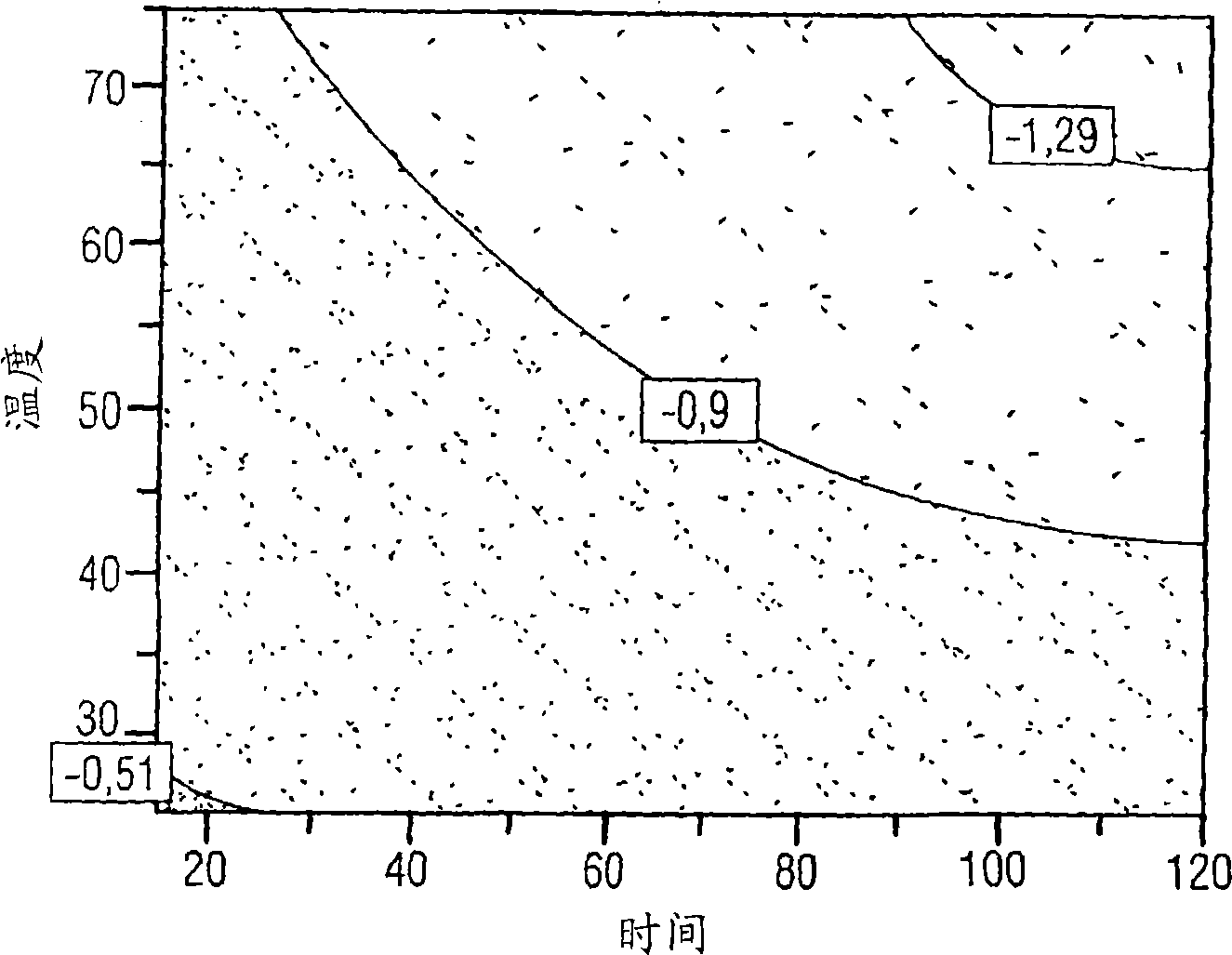

[0147] The cleaning method of the present invention is carried out on glass tubes having the above composition and dimensions. In this case, the shrinkage (“shrinkage”) of the individual glass tubes in mm at different pH values as a function of the different cleaning times and cleaning temperatures was determined.

Description of drawings

[0148] The results are sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap