Electromagnetic needle selector for jacquard

A technology of jacquard machine and needle selection, applied in the direction of jacquard machine, textile, textile and paper making, etc., can solve the problems of large remanence, poor reliability, coil lead breakage, etc., so as to omit the reset coil, solve the problem of easy breakage, and overcome the residual magnetism. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

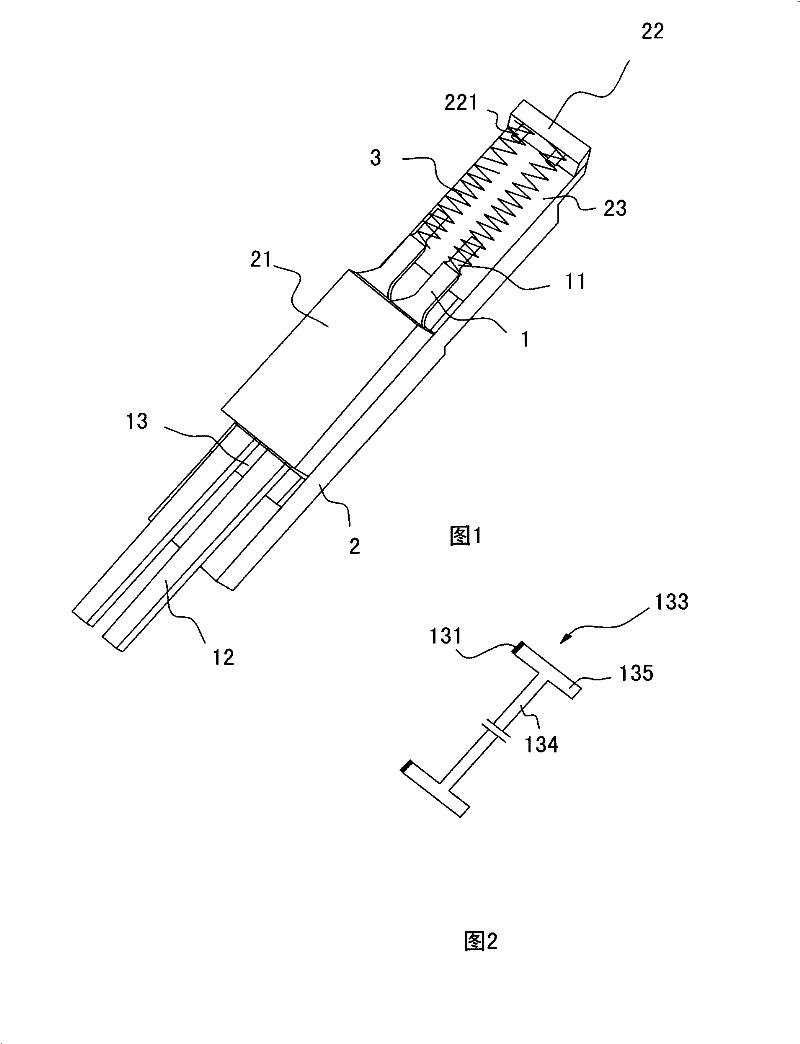

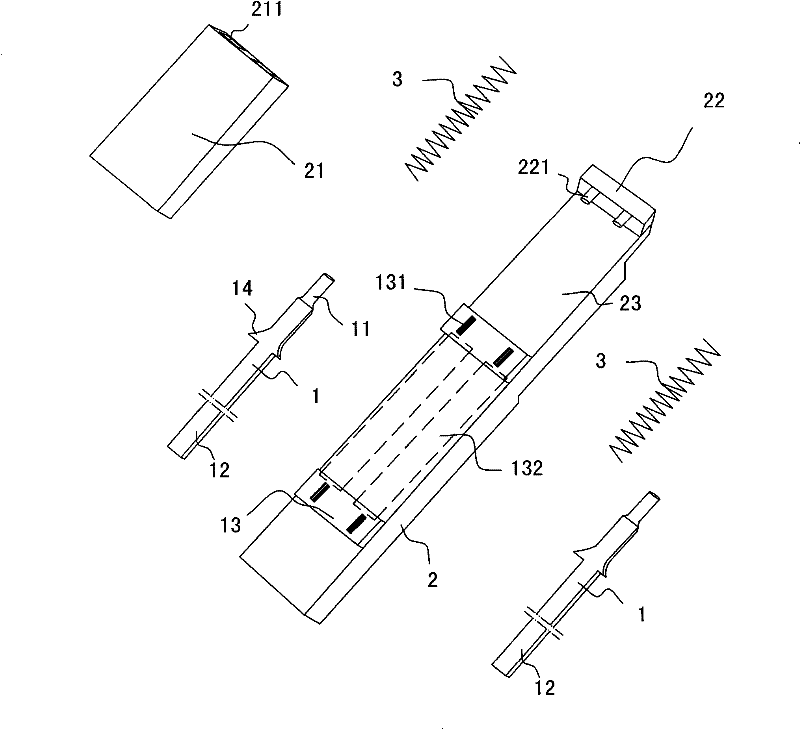

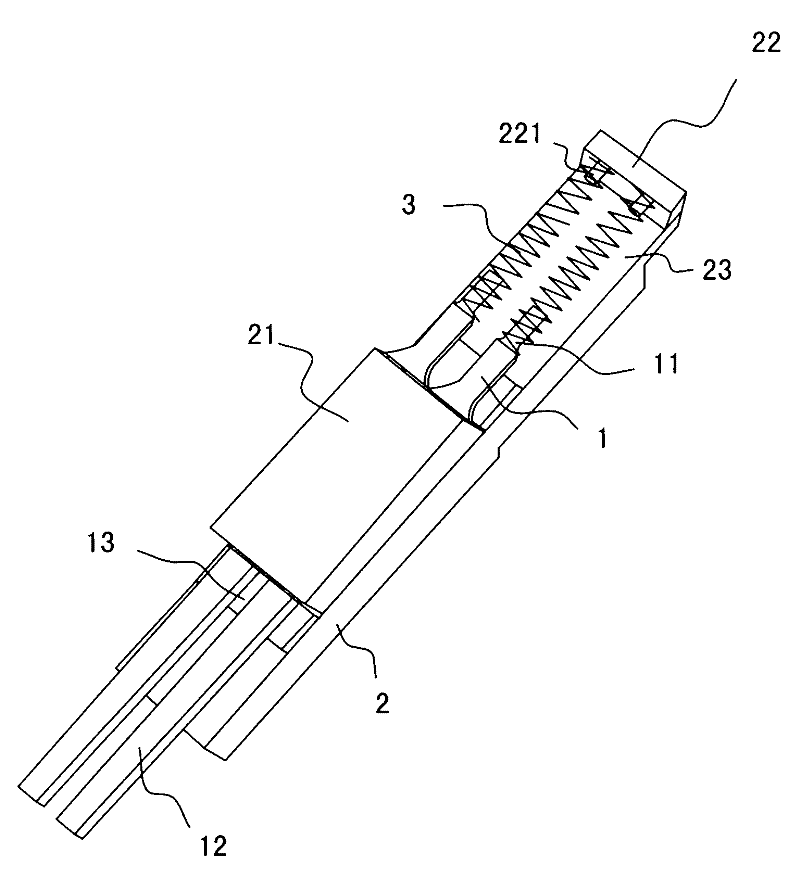

[0017] see figure 1 and combine figure 2 , image 3 . The whole needle selection device is composed of valve body 2, two armature needles 1, two springs 3 and spring seats 22 thereof. The exposed abutment 13 and the working surface 23 of the valve body 2 are an integral part, and the protrusion 21 can be an integral part with the working surface 23 of the valve body 2, or can be matched with the exposed abutment 13, and a dovetail groove plug-in connection is adopted As a whole, the advantage of this is that it is easy to install. The front shape of the iron core 133 is "I" shape, and the vertical piece 134 is used to wind the working coil 132. When installing, it is placed laterally in the accommodating chamber of the valve body 2 at the bottom of the bump 21, and the upper and lower horizontal pieces 135 The two side end faces 131 of the exposed abutment 13 extend out, but are flush with the surface of the exposed abutment 13. The bump 21 is just above the working coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com