Gear noise preventing device for manual transmission

A manual transmission, noise prevention technology, applied in the direction of transmission control, belt/chain/gear, elements with teeth, etc., can solve the problems of increasing the operating load of the shift lever and excessively increasing the stroke of the pre-blocking fork shaft, etc. To achieve the effect of preventing gear noise, suppressing the increase of operating load, and good operating feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be described below with reference to the accompanying drawings. The present invention will be described in the case of applying the present invention to a synchromesh manual transmission having six forward gears and one reverse gear mounted on a front engine front drive (FF) vehicle.

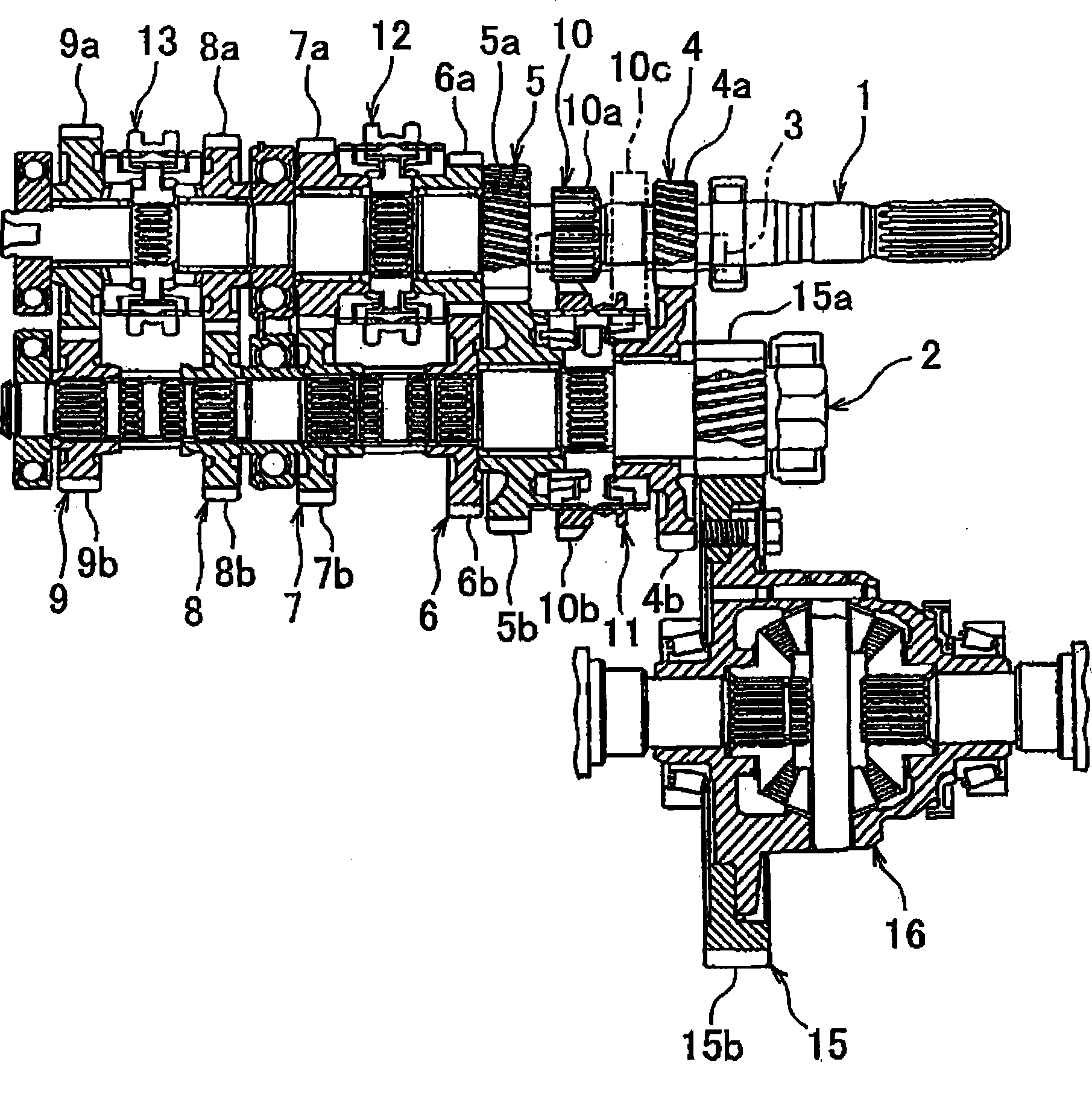

[0044] figure 1 is a side view of the gear arrangement of the manual transmission according to the present embodiment, in which a part of the gear arrangement is shown in section. figure 1 The gear arrangement shown is housed in a transmission housing (not shown). Input shaft 1, output shaft 2 and reverse shaft 3 (in figure 1 shown by double-dashed lines) are arranged parallel to each other and are rotatably supported by the transmission case.

[0045] The input shaft 1 is coupled to a crankshaft (not shown) of the engine via a clutch mechanism. When the clutch mechanism is engaged, the rotational driving force of the engine is input to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com