Cluster industrial robot failure diagnosis method based on outlier excavation

An industrial robot and fault diagnosis technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of small detection delay, inability to diagnose unknown faults, and inability to use industrial robots to improve reliability, The effect of avoiding equipment failure and ensuring reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

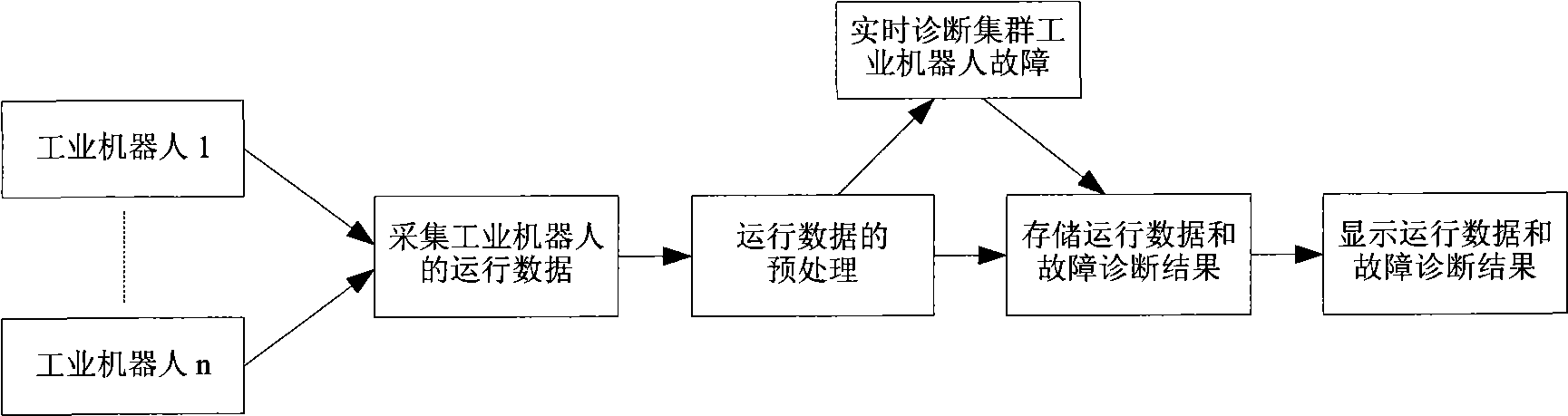

[0019] Such as figure 1 As shown, the present invention includes the following steps: collecting operating data of clustered industrial robots, preprocessing industrial robot operating data, performing real-time fault diagnosis on industrial robots, storing operating data and fault diagnosis results, and displaying operating data and fault diagnosis results. details as follows:

[0020] 1. The operation data of the cluster industrial robot is obtained from the controller of the cluster industrial robot by the data acquisition card. The data acquisition card has multiple input channels and can simultaneously collect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com