LED and relevant backlight module

A technology of light emitting diodes and backlight modules, which is applied to optical elements, optics, light sources and other directions used to change the spectral characteristics of emitted light, can solve problems such as uneven brightness, insufficient brightness, and increased cost, and achieve large design flexibility, extreme Competitive, low module cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

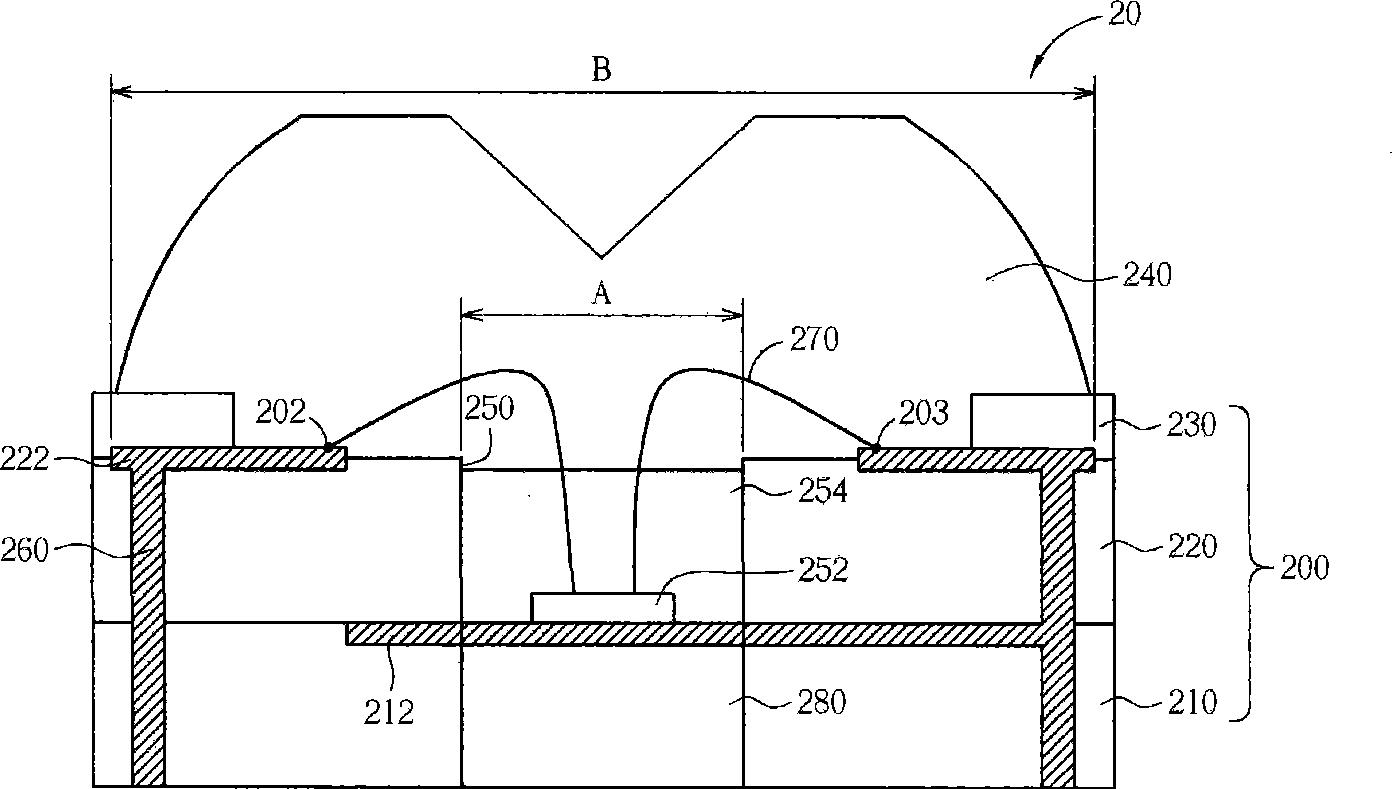

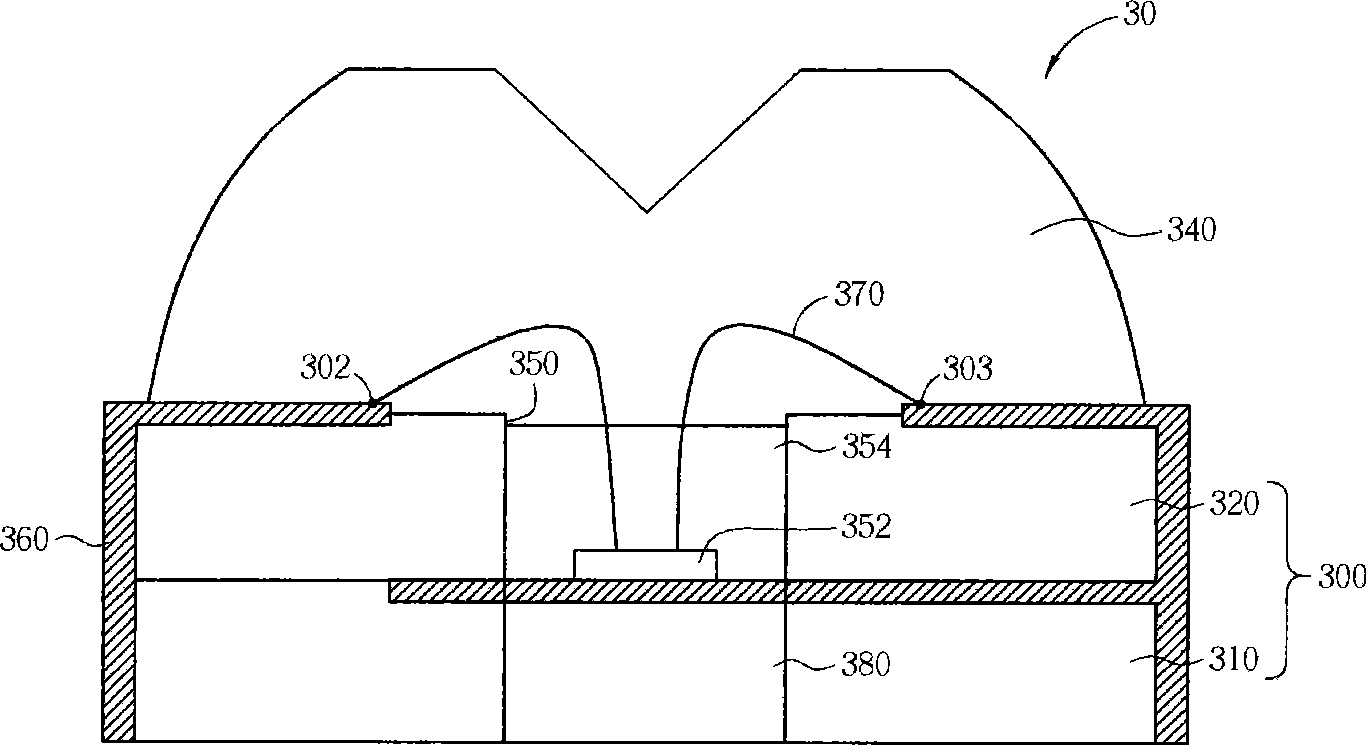

[0045] Please refer to figure 2 , image 3 . The light emitting diode 20, 30 of the present invention comprises a base structure 200, 300, a light emitting diode chip 252, 352, a phosphor layer 254, 354 and a lens (lens) 240, 340, wherein the base structure 200, 300 has a groove 250, 350, the light-emitting diode chip 252, 352 can be placed therein, and the phosphor layer 254, 354 is arranged in the groove 250 and covers the light-emitting diode chip 252, 352, in order to convert the chip light emission wavelength into other light emission wavelength and increase the light color uniformity of the light emitting diodes 20, 30, the lens 240, 340 is arranged on the base structure 200, 300, in order to adjust the light emitted by the light emitting diode chip 252, change its luminous field shape, and the base structure 200 , 300 further includes at least one conductive terminal 202 , 203 , 302 , 303 for providing the voltage required for the LED chip 252 , 352 to emit light.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com