Overhead network barrier-clearance and detection robot

An overhead line and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of no automatic obstacle clearance, high labor intensity, low efficiency, etc., and achieve the effect of convenient long-distance control, improved work efficiency, and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

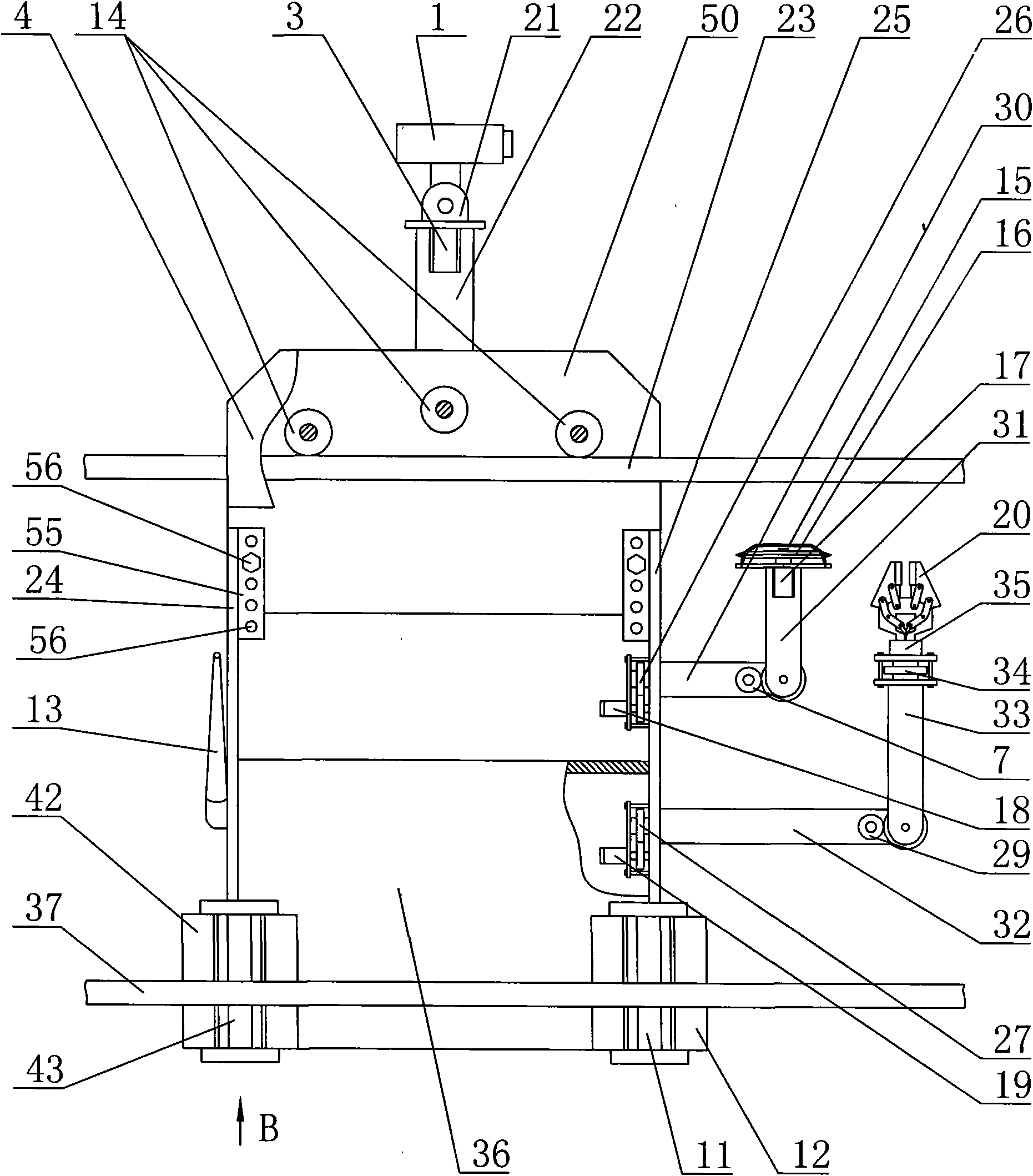

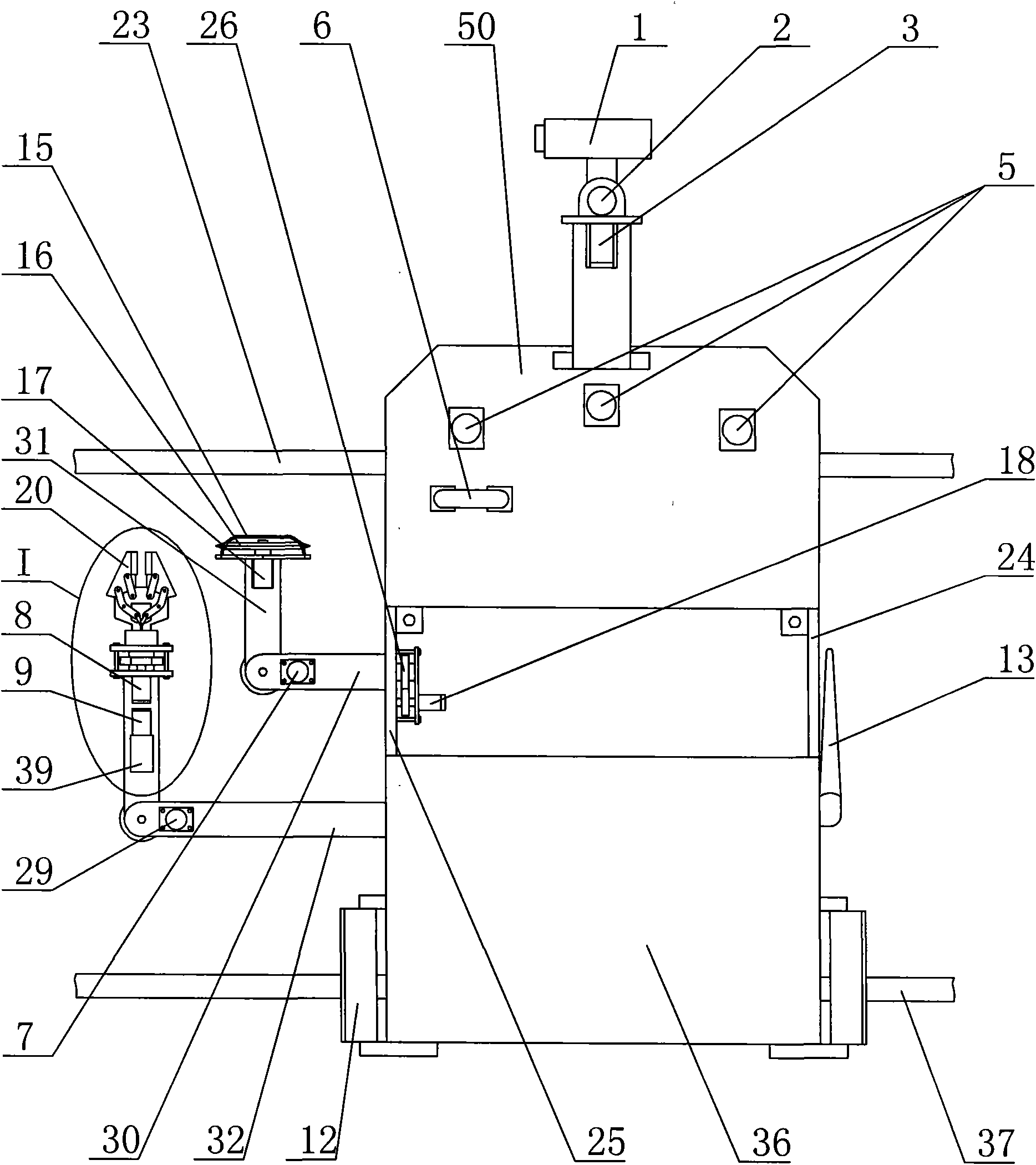

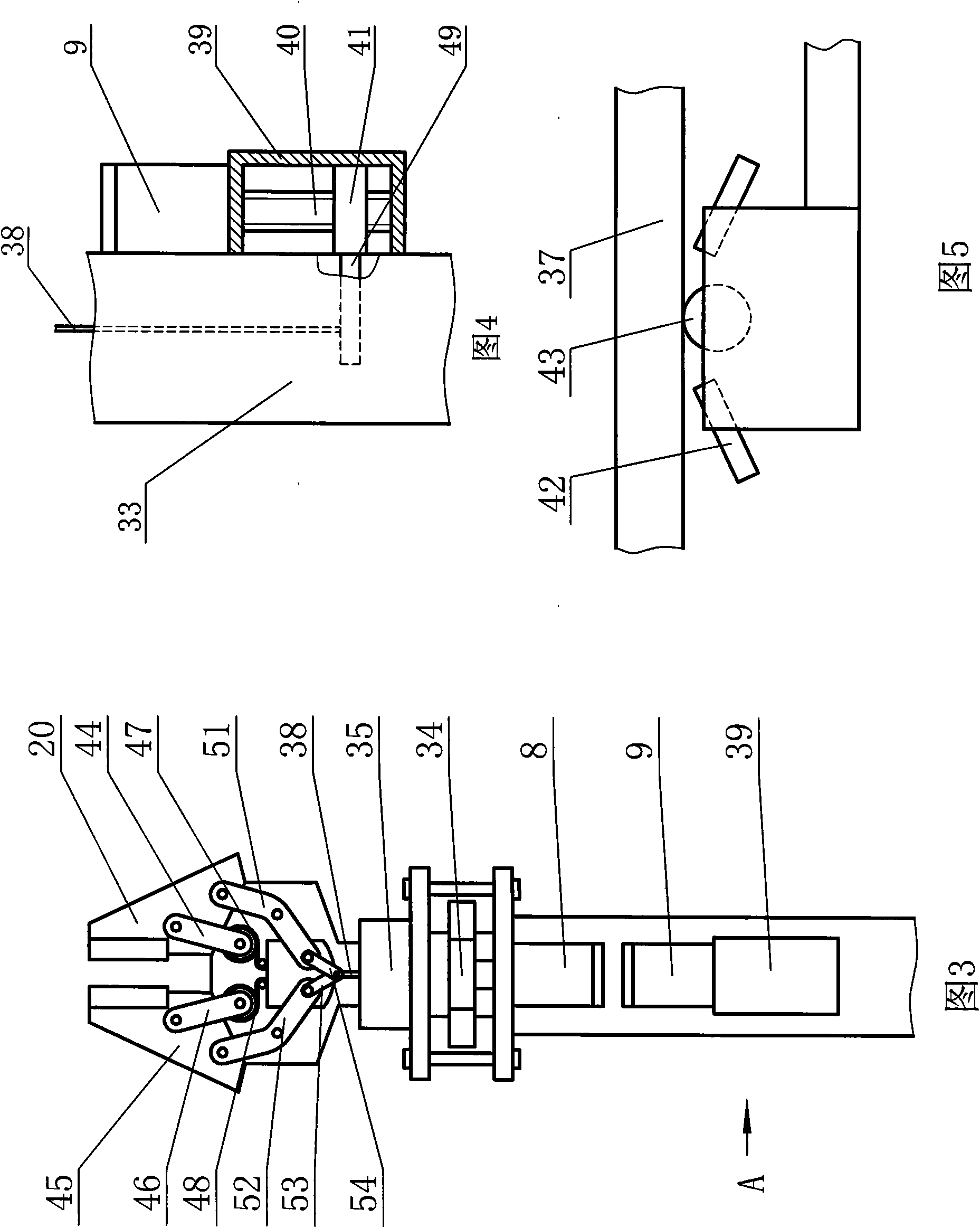

[0009] The overhead line obstacle removal detection robot of the present invention comprises an electrical box 36, and a first side plate 24 and a second side plate 25 are installed on the electrical box 36, and the first side plate 24 and the second side plate 25 are installed on the top of the first side plate. plate 50, the second mounting plate 4 is installed on the first mounting plate 50, the electrical box 36, the first side plate 24, the second side plate 25 and the first mounting plate 50 are connected to form a body, the body structure is simple, the volume is small, and the weight It is light, easy to install on overhead lines, and can minimize the impact of the robot on overhead lines; the second mounting plate 4 is separated from the first mounting plate 50 by a certain distance, and the second mounting plate 4 is equivalent to the suspension arm. Three drive wheels 14 are installed between the mounting plate 4 and the first mounting plate 50, three travel motors 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com