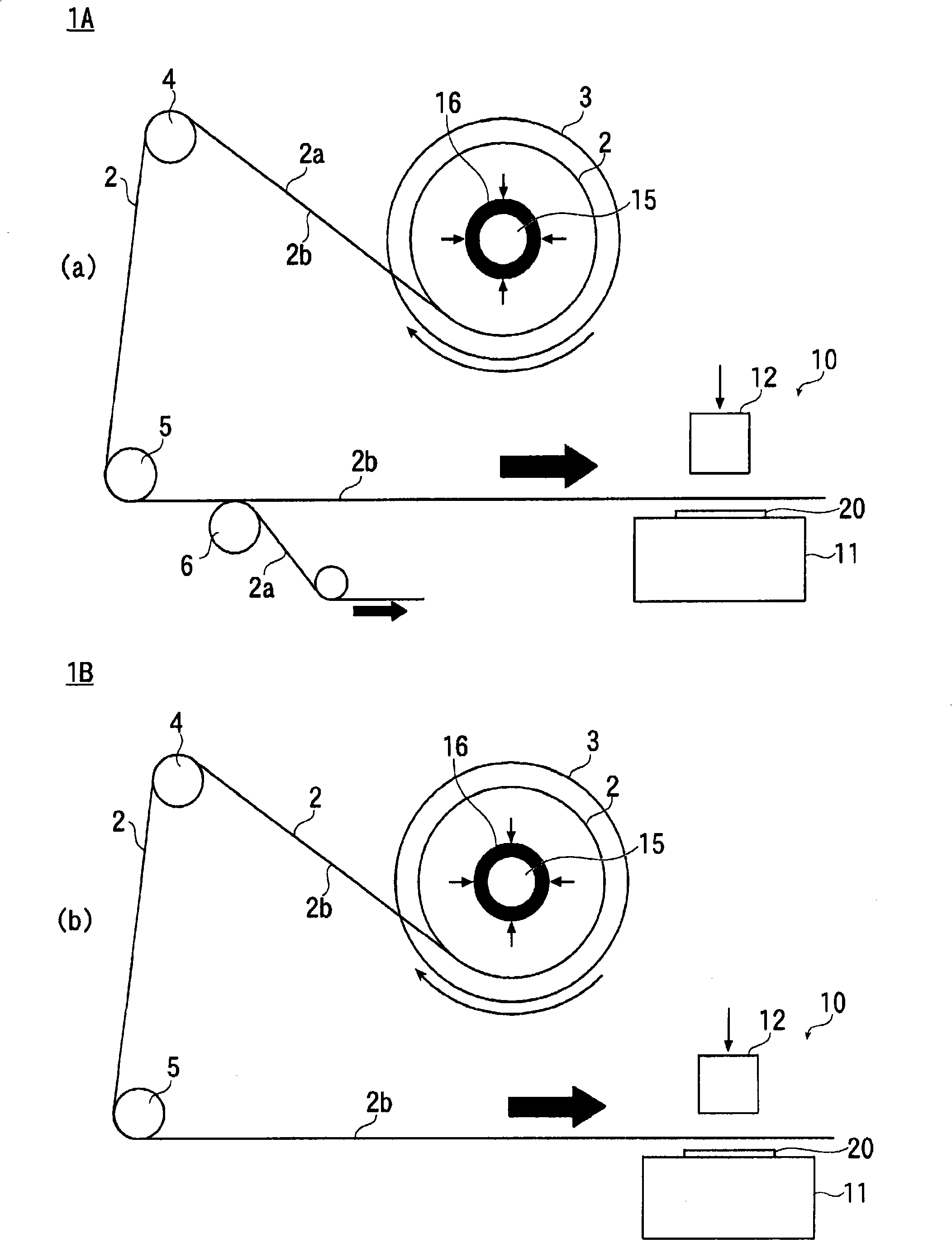

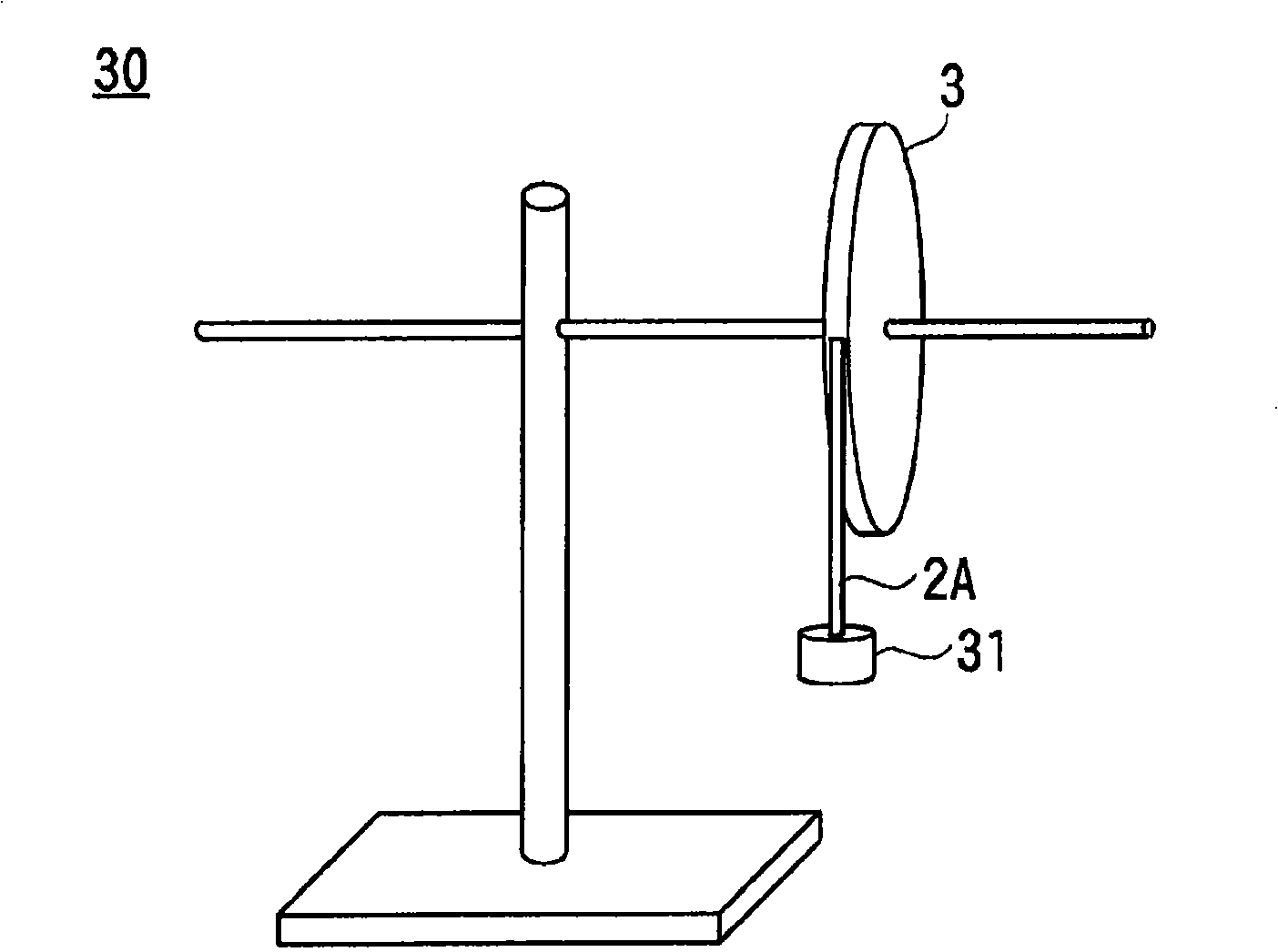

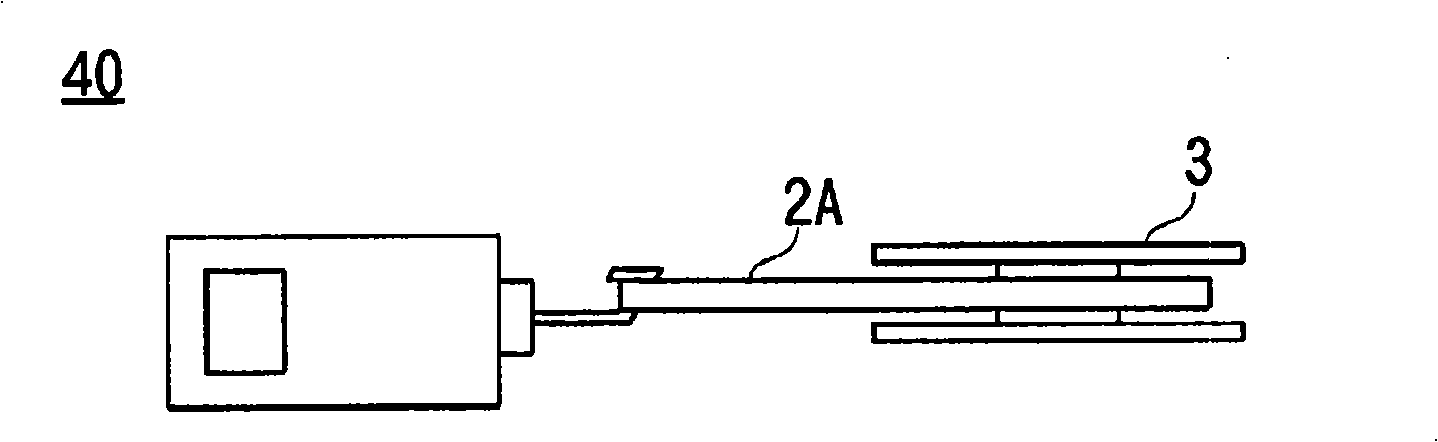

Sticking method of adhesive film and winding reel of adhesive film

A technology of bonding film and reel, applied in the direction of winding strips, transportation and packaging, sending objects, etc., can solve the problems of winding deviation, film slipping and winding gaps, etc., to prevent winding gaps and winding offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Examples and comparative examples are given below to specifically illustrate the present invention, but the present invention is not limited to the following examples.

[0054] In this example, as the anisotropic conductive adhesive film, a film formed by applying an anisotropic conductive adhesive with a thickness of 0.018 mm to a release sheet having a width of 2 mm in a film form was used.

[0055] The viscoelasticity of this anisotropic conductive adhesive film is 6×10 under the condition of the measuring needle PP20 in a temperature environment of 30°C 4 Pa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap