Clutch with dual area piston and independent pressure control

A clutch and clutch assembly technology, applied in the field of clutches, can solve problems such as poor maximum torque control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses.

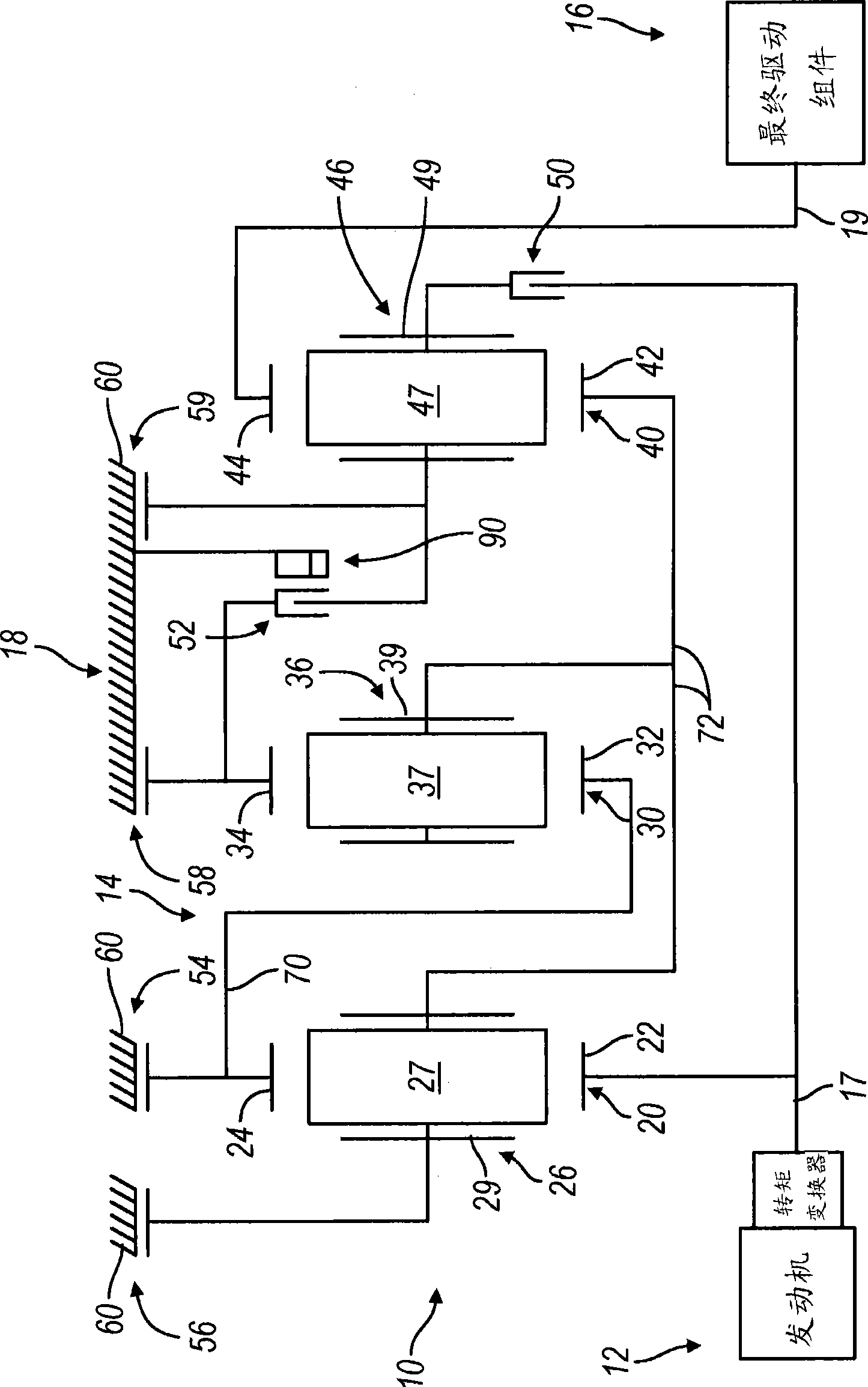

[0019] now refer to figure 1 , where a powertrain of a motor vehicle is shown, generally designated by reference numeral 10 . The motor vehicle powertrain 10 includes an engine and torque converter 12 , a multi-speed automatic transmission 14 , and conventional final drive components 16 .

[0020] Automatic transmission 14 includes an input shaft 17 connected to the engine and output of torque converter 12 , a planetary gear arrangement 18 , and an output shaft 19 connected to final drive assembly 16 . The planetary gear arrangement 18 includes a first planetary gear set 20 , a second planetary gear set 30 and a third planetary gear set 40 .

[0021] The first planetary gear set 20 includes a first sun gear 22 , a first ring gear 24 and a first planetary gear assembly 26 . The first planetary gear assembly 26 includes a first plurality of planet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com