Covering element comprising a sound absorbing element

A technology for covering components and components, used in household components, vehicle parts, transportation and packaging, etc., can solve the problem of weight of the final product, and achieve the effect of low cost, strong sound absorption ability, and good acoustic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

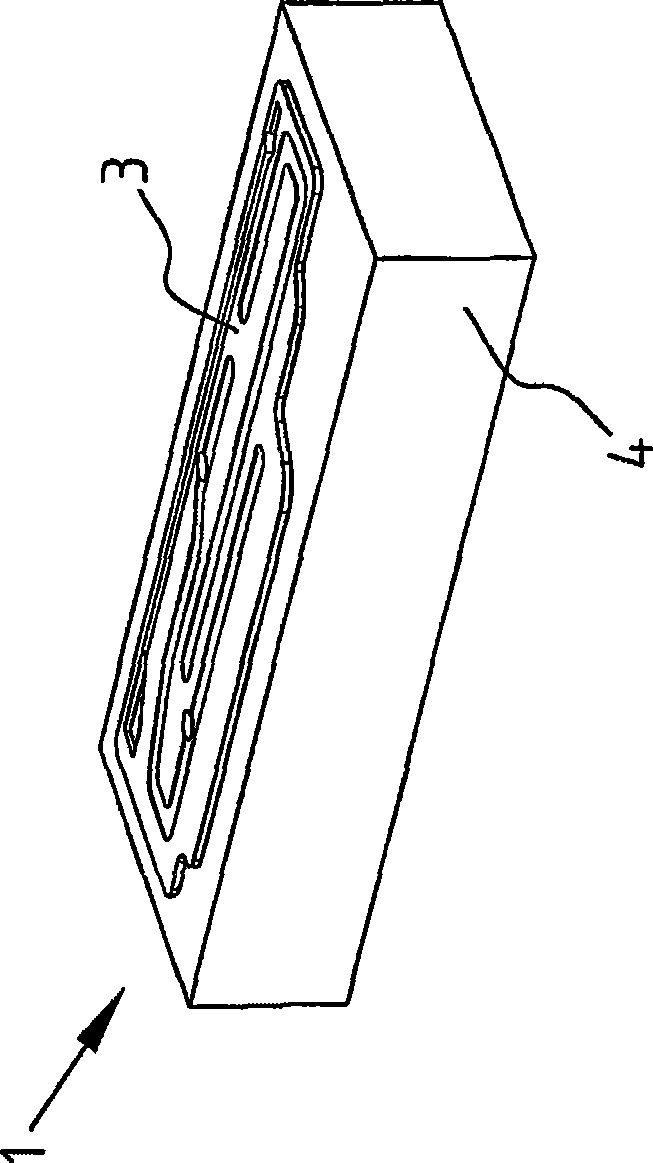

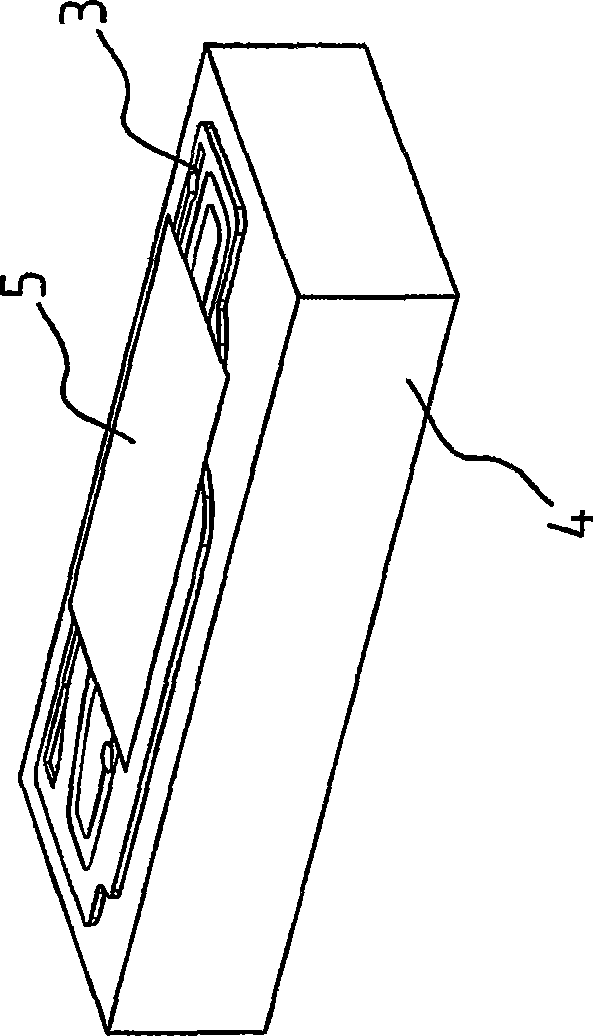

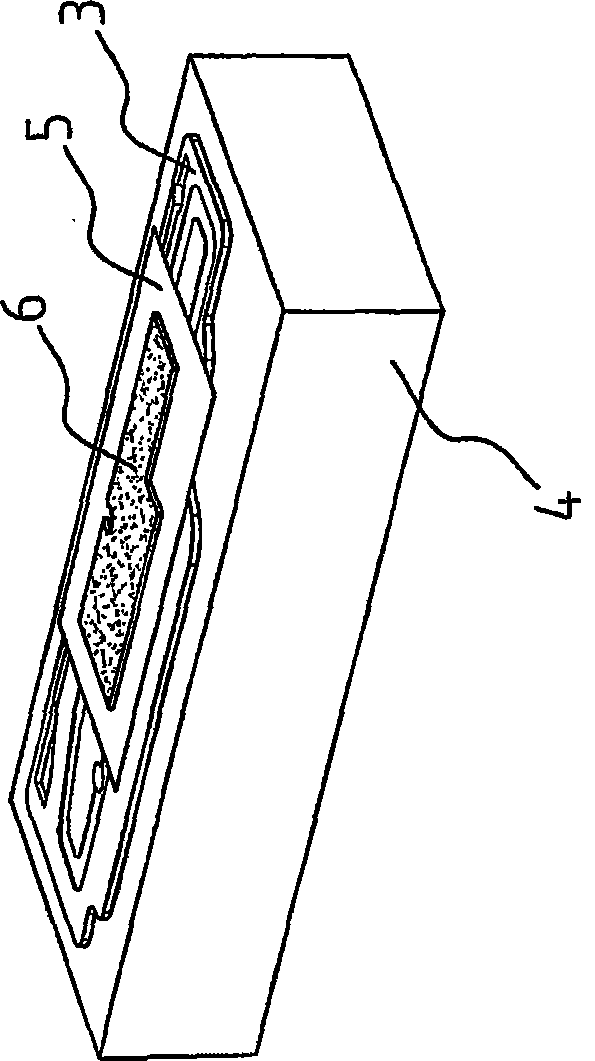

[0057] Figure 1A A part of the injection mold 1 for producing the covering element 2 is shown. Said mold part comprises a forming part 3 for forming the covering element 2 and also comprises a metal core 4 . Figure 1B The application of an adhesive layer 5 of thermoplastic material, preferably polypropylene, to the shaped part 3 of the injection mold 1 is shown. Such as Figure 1C As shown, the sound absorbing element 6 is arranged on the adhesive layer 5 . Here, it should be noted that in this embodiment, the injection mold is arranged horizontally to facilitate the introduction of the adhesive layer and the sound-absorbing element. However, it is also possible to arrange the injection mold vertically. Next, said mold is preferably provided with means for arranging the adhesive layer and the sound-absorbing elements. Figure 1C The sound absorbing element 6 preferably comprises a polyurethane foam structure. Depending on the position of the covering element on the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com