Gap-bridging device for train platforms

A technology of equipment and platform, applied in the field of lap joint equipment and lap joint equipment in the car door area, it can solve the problems of lap plate jamming and low structure height, and achieve the effect of stable operation, compact structure and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

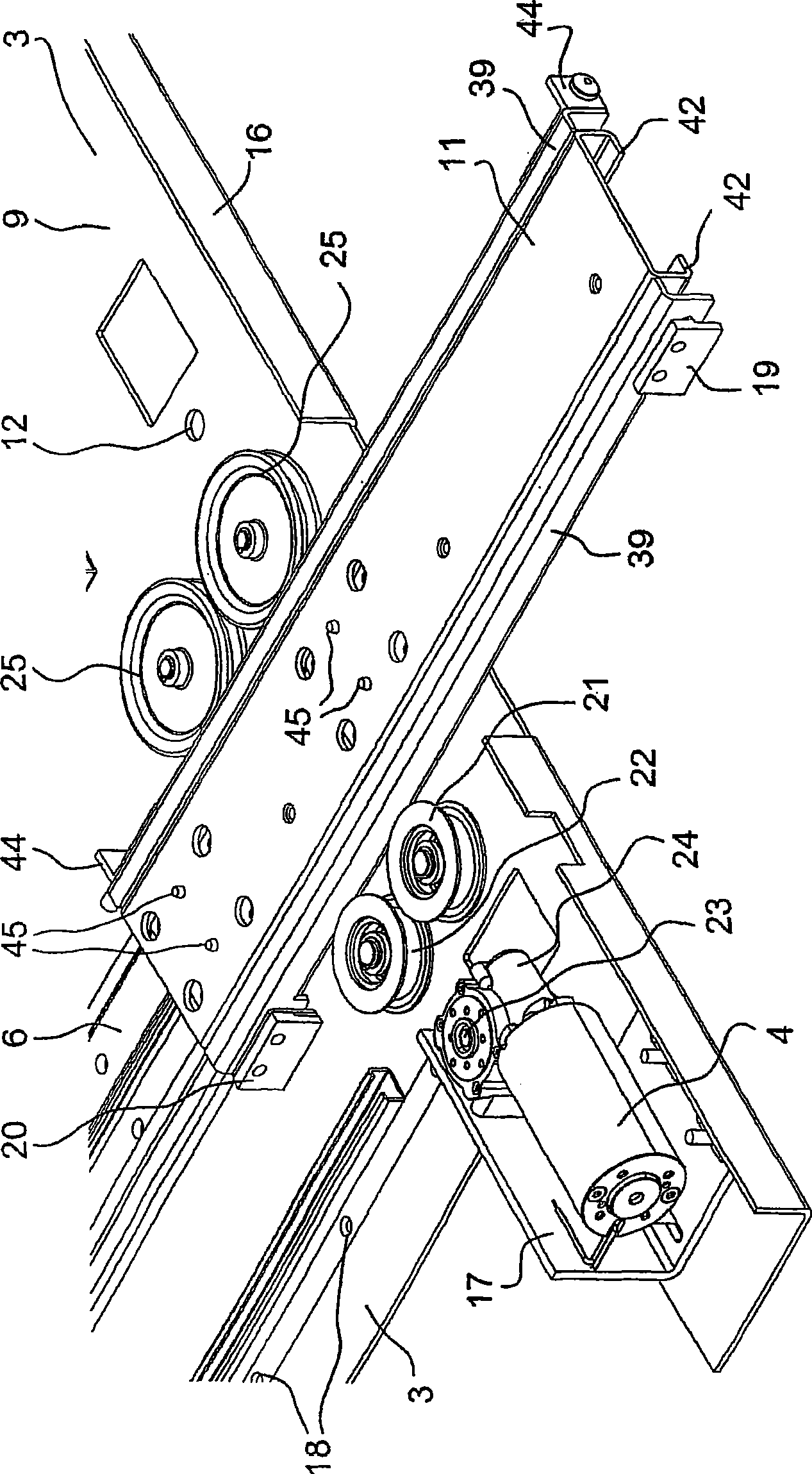

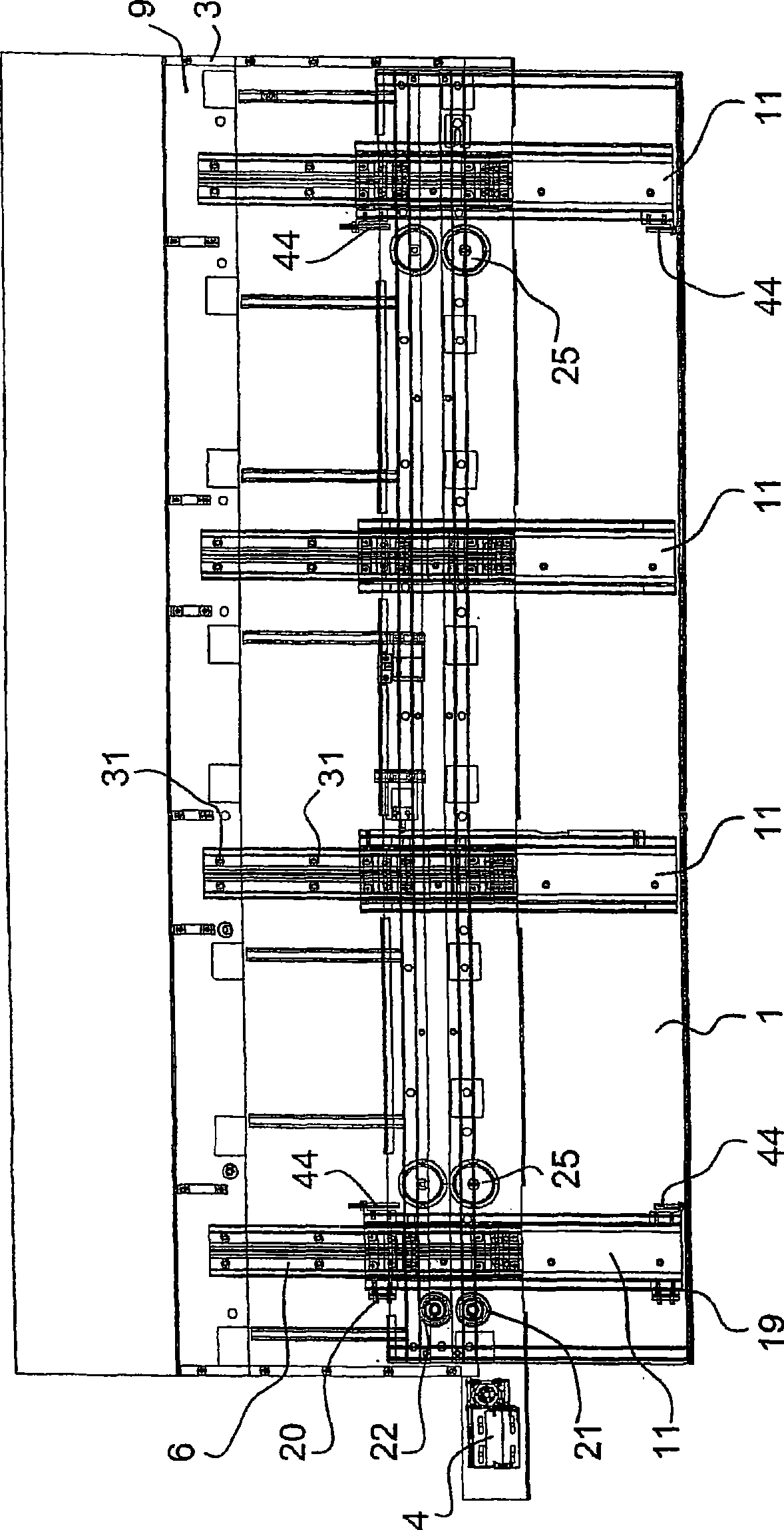

[0026] The invention is explained in more detail below with reference to an exemplary embodiment in connection with the drawings. It is emphasized here that the illustrated embodiments should only serve to support and demonstrate the practice of the invention and should not limit the subject-matter as in the claims appended hereafter.

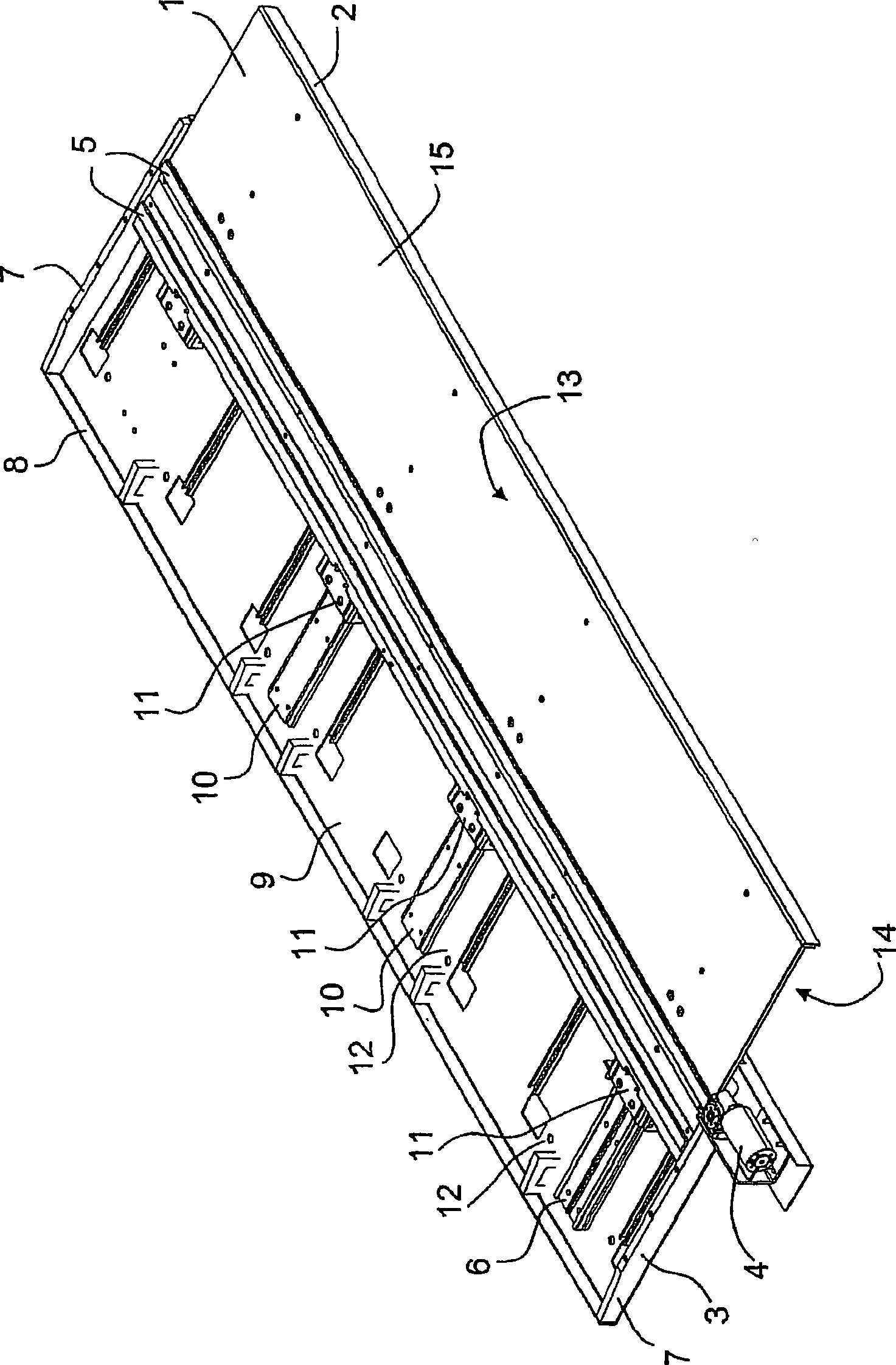

[0027] figure 1 A perspective view of the splicing device is shown. The splicing device here comprises a splicing plate 1 which is movably mounted relative to a housing 3 . The housing 3 is either screwed to the platform or fixed to the rail vehicle. In other words the proposed splicing device can be used for bridging gaps by being fixed on the platform and protruding after the train has driven in, or by being fixed in the door area of the rail vehicle and protruding in the direction of the platform after the arrival of the train , the lapping plate can also be used to bridge the gap between the platform and the rail vehicle. Preferably a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com