Two-way directional force output air-powered flexible drive device

A driving device and flexible driver technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of poor radial rigidity, small stroke, single force, etc., and achieve the effect of large power/mass ratio and large working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

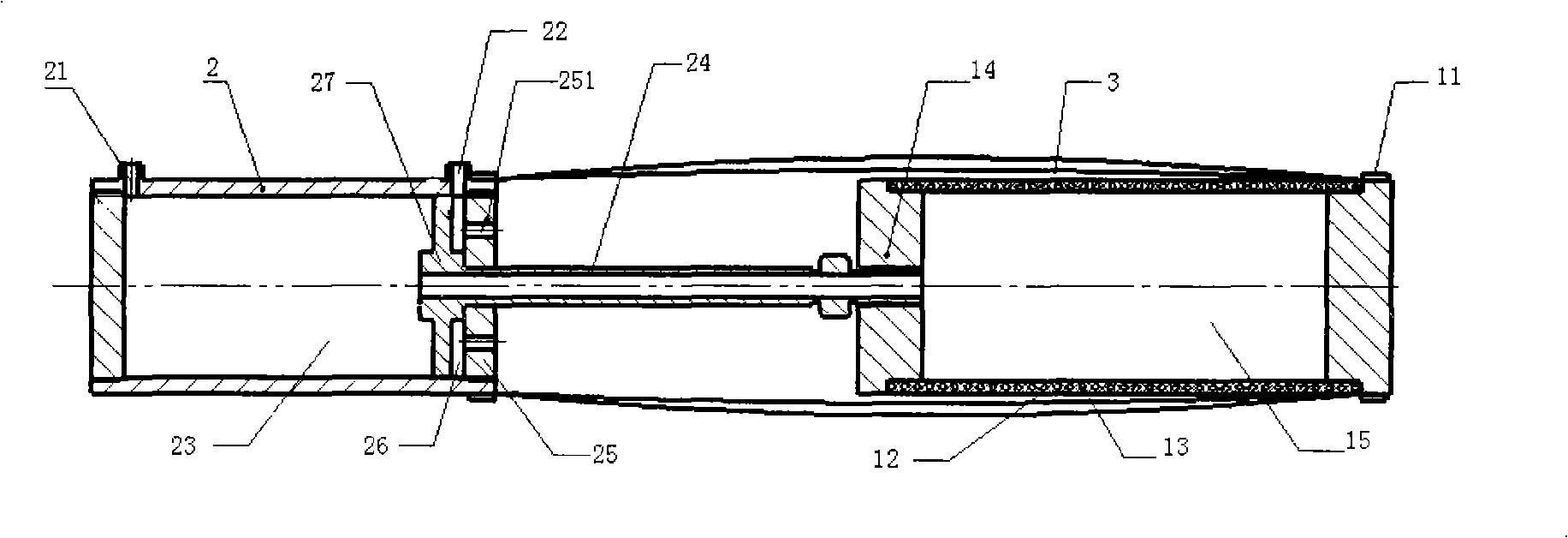

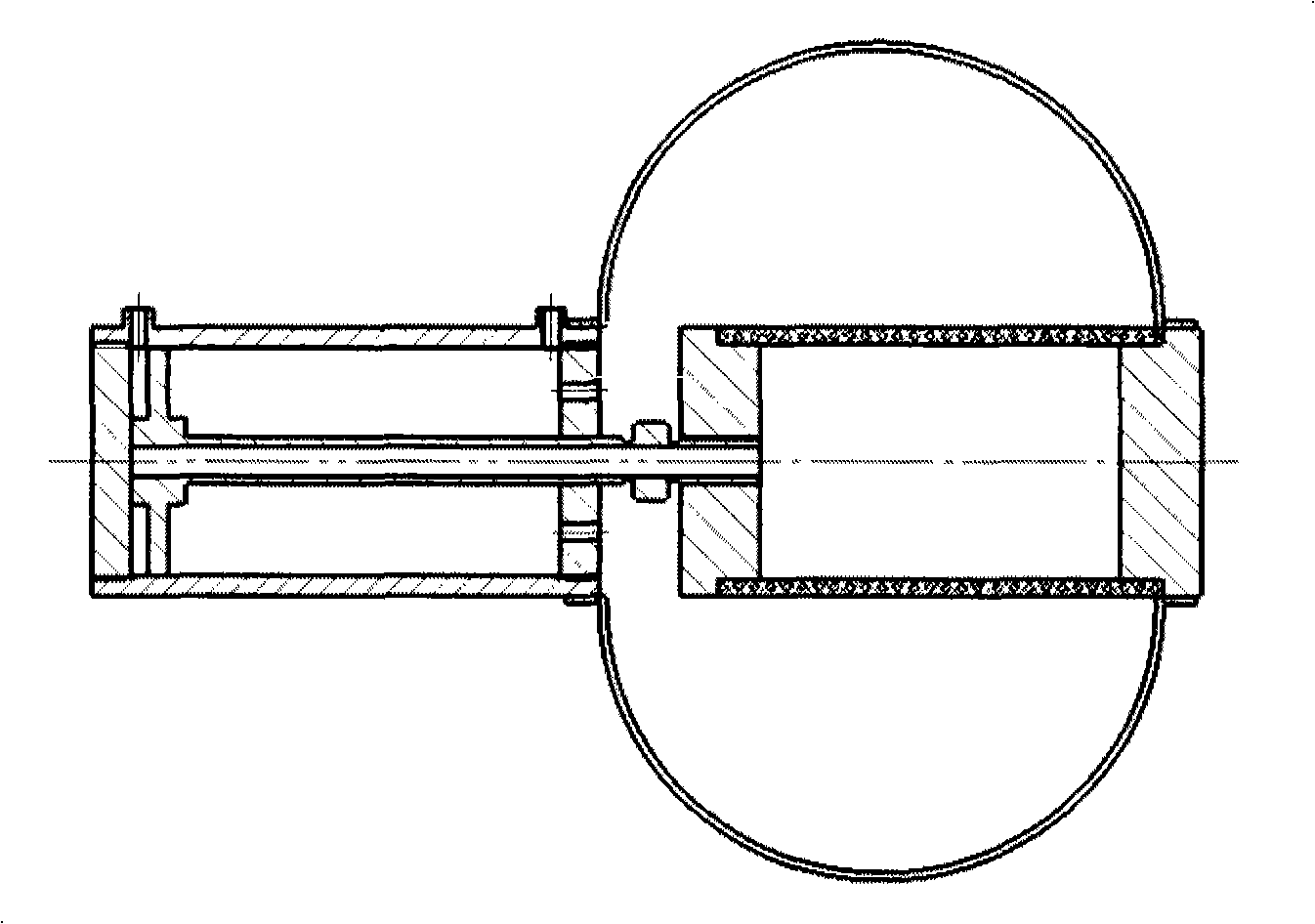

[0013] combine figure 2 , 3 , to further illustrate the present invention:

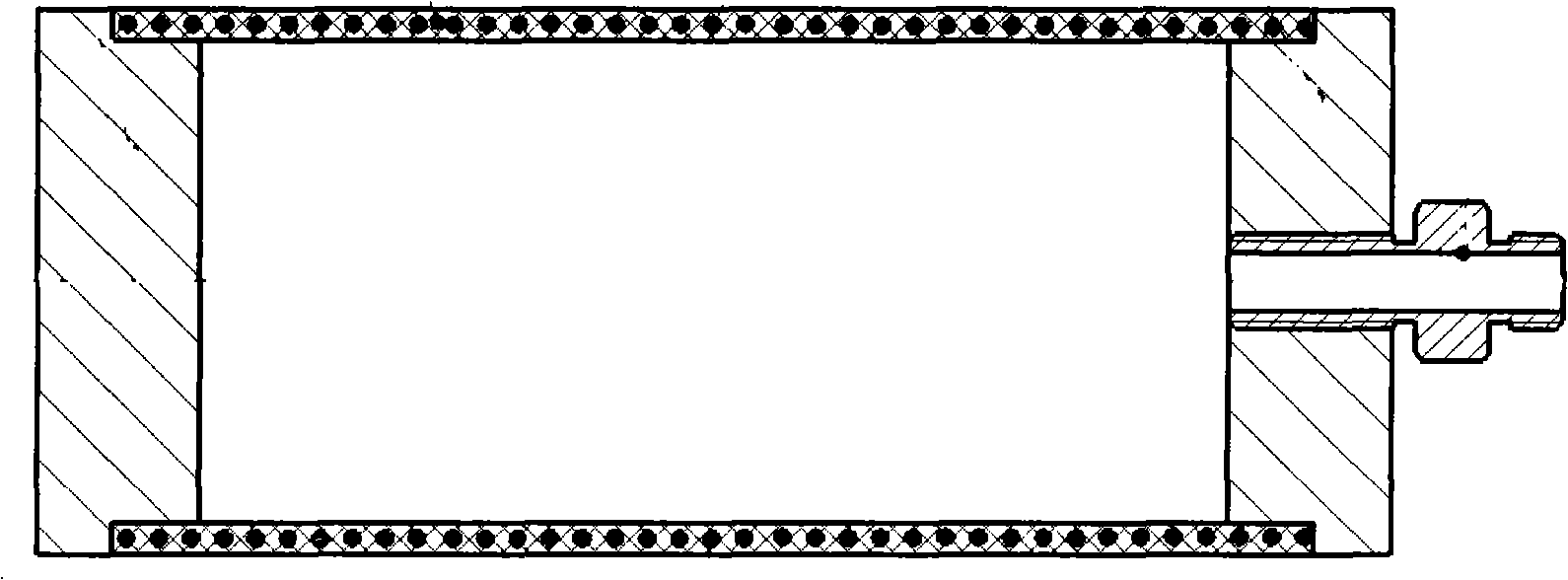

[0014] The pneumatic flexible driving device with two-way force output includes a pneumatic flexible driver composed of end caps 11, 14, a first rubber tube 12, and a spring 13 nested in the wall of the first rubber tube 12. The pneumatic flexible driver There is a piston cylinder 2 in the front, and a second rubber tube 3 is airtightly sleeved outside the pneumatic flexible driver, and the front end of the second rubber tube 3 is airtightly sleeved on the rear end cover 25 of the piston cylinder 2 On; described piston cylinder 2 has front air port 21 and rear air port 22, and piston 27 is positioned between described front air port 21 and rear air port 22; Described piston 27 connects a hollow piston rod 24, and described piston The rear end of the rod 24 is connected to the front end cover 14 of the pneumatic flexible driver, and the piston rod 24 communicates with the front inner cavity 23 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com