Test method and device of variable-paddle bearing friction moment of wind-driven generator and application thereof

A technology for wind turbines and pitch bearings, applied in mechanical bearing testing, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as not accurately considering the influence of load on the friction torque of pitch bearings, and achieve Good technical support, reasonable results, accurate friction torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

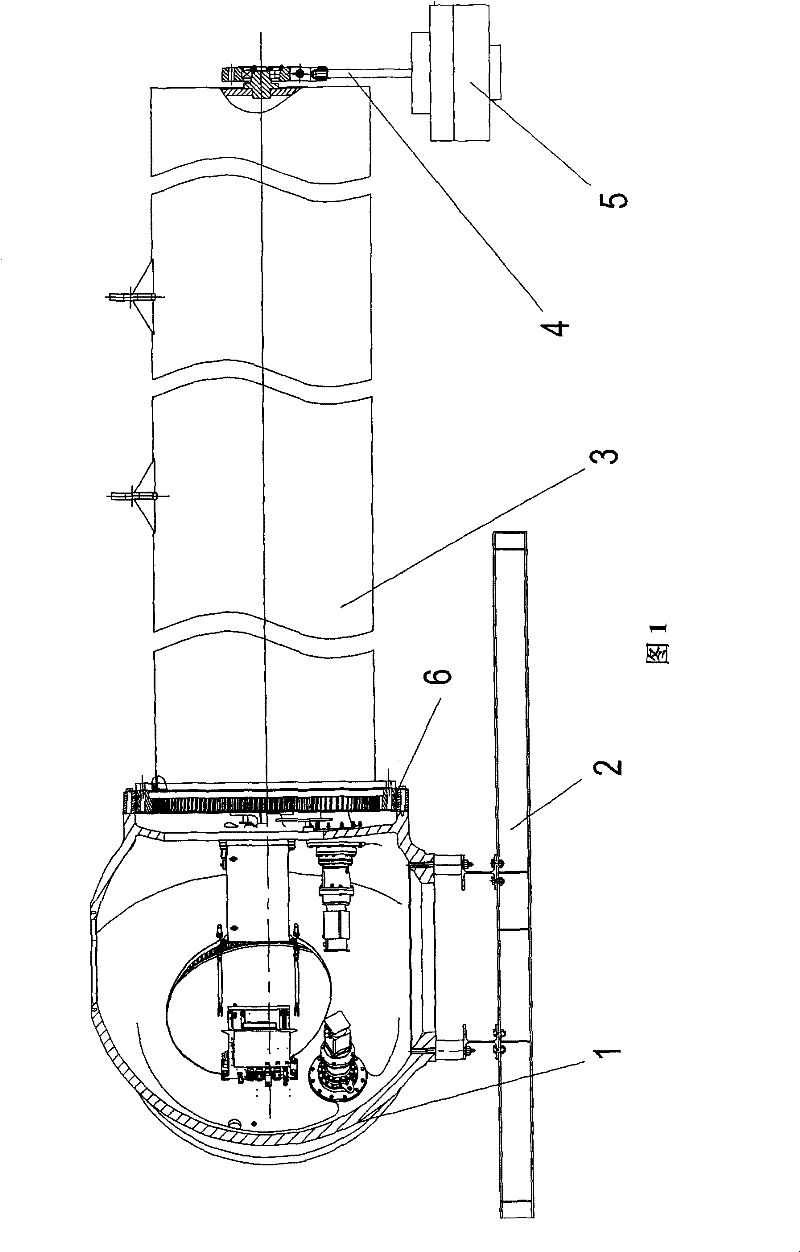

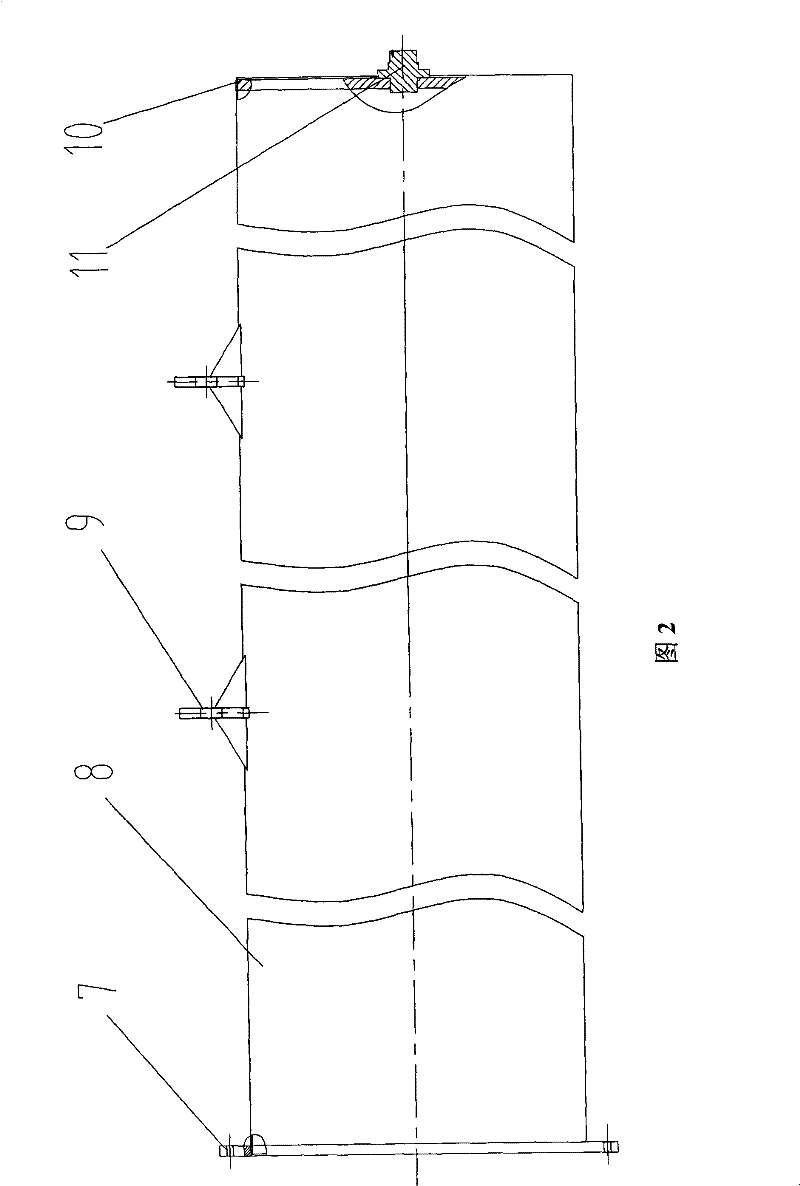

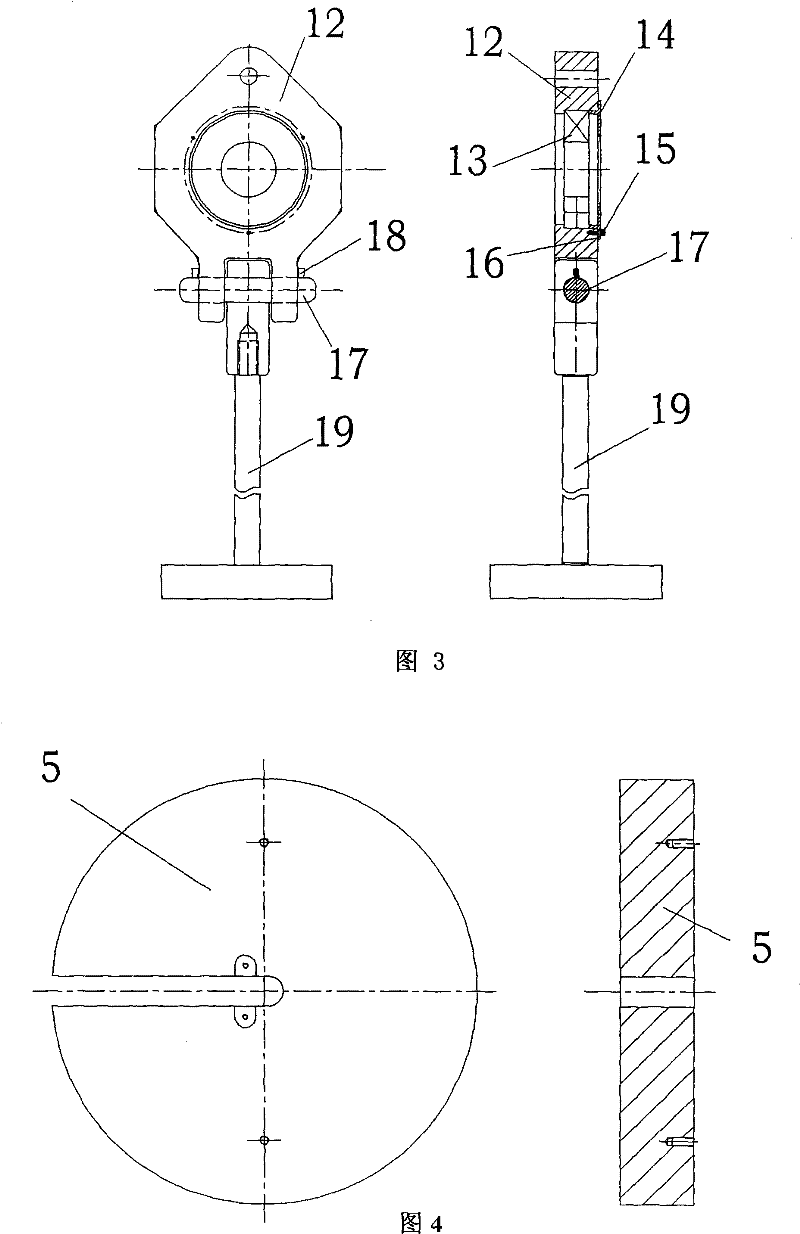

[0019] Accompanying drawing has provided a kind of schematic diagram of the present invention, will further describe the present invention below in conjunction with accompanying drawing.

[0020] by attaching figure 1 It can be seen that the present invention is a testing device, which mainly includes a hub assembly system 1, a fixed tooling 2, a cantilever beam 3, a loading device 4, a counterweight 5, and a pitch bearing 6, etc. The test device is a simulation test device for accurately measuring the friction torque of the pitch bearing 6 on the ground, and it measures the friction torque of the pitch bearing 6 through the ground test on the ground; the process of measuring the friction torque of the pitch bearing by the test device is: The hub assembly system 1 with the pitch bearing 6 installed is installed and fixed on the fixed tooling 2, and then the simulated cantilever beam 3 is installed at the pitch bearing 6, and a loading device 4 for applying force is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com