Mask-plate bearing bed and photo-etching device and double-exposure method thereof

A technology of lithography equipment and mask plate, which is applied in the field of semiconductor manufacturing process and can solve the problems of inaccurate imaging and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and features of the present invention more obvious and understandable, the present invention will be further described by giving preferred embodiments and in conjunction with the accompanying drawings.

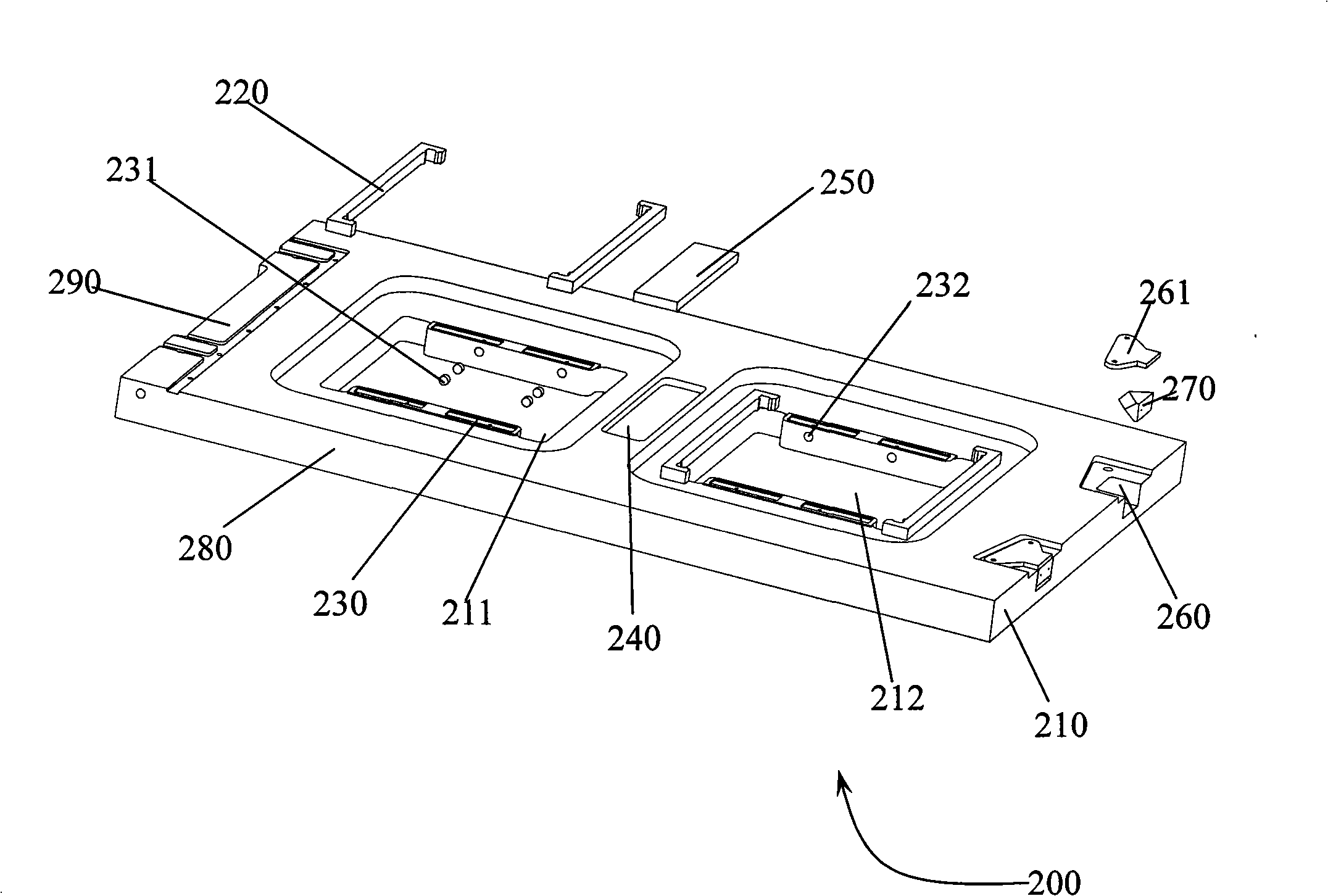

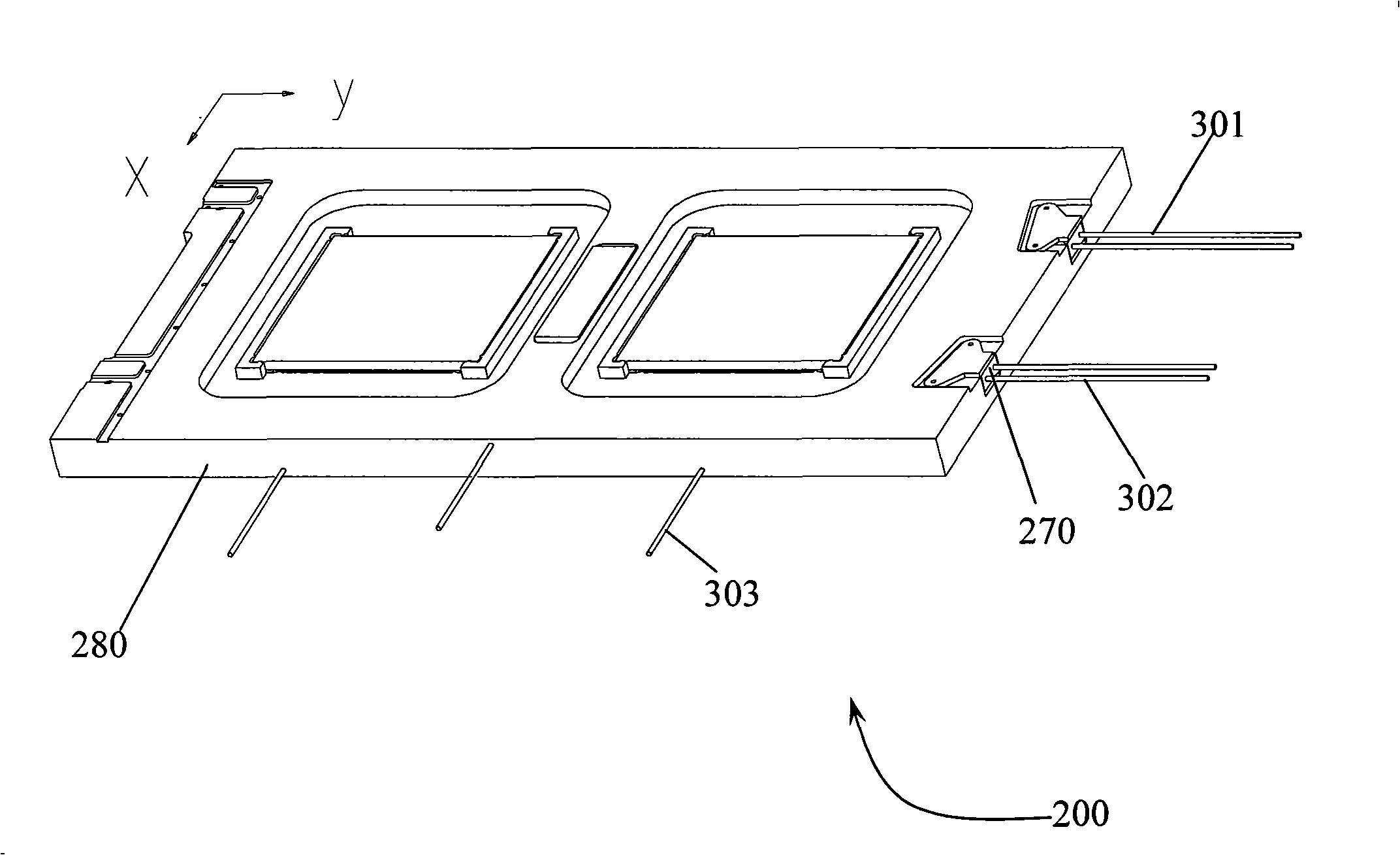

[0030] An embodiment of the present invention provides a reticle holder capable of installing two reticles at the same time, please refer to figure 2 , which is a schematic diagram of the structure of the reticle holder. The reticle holder 200 includes:

[0031] The mask holder 210 is an important part, and other parts play an auxiliary role in the installation and positioning of the mask on the basis of the holder.

[0032] The first reticle installation position 211 and the second reticle installation position 212 are arranged on the reticle holder 210, and reticle A (4) and reticle B (5) can be installed at the same time on these reticle installation positions , the size and structure of the two installation positions are exactly the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com