Method of preventing the formation of inkjet printing artefacts

An inkjet printer, printing direction technology, applied in printing and other directions, can solve the problems of reducing the total production volume, reducing the production volume, complicated reasons, etc., to achieve the effect of reducing implementation time, reducing costs, and overcoming image defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

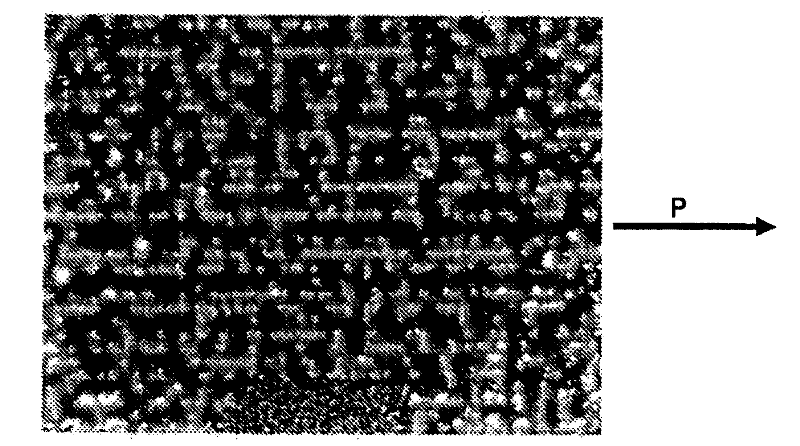

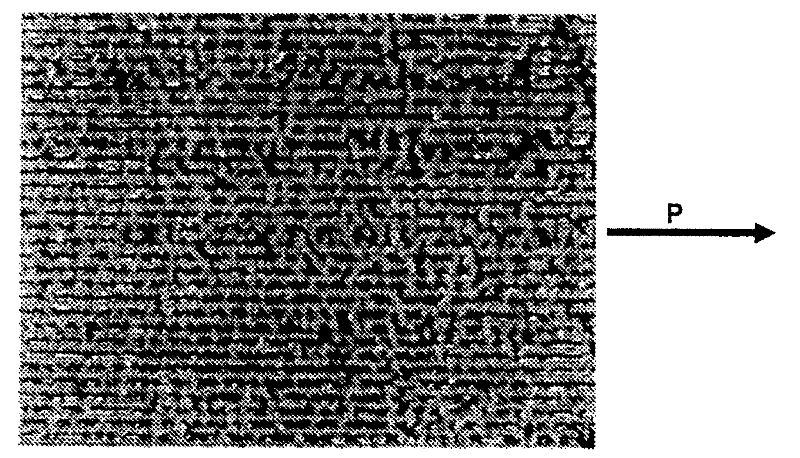

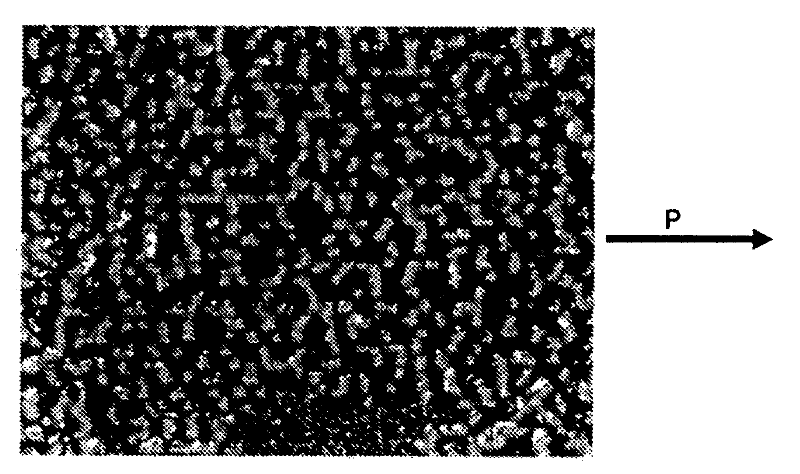

[0038] The present invention solves the problem of chain formation by reducing the size of certain selected droplets within the printed pattern, thereby inhibiting coalescence on the substrate. Figure 5 shows a magnified image of a print made with UV-curable ink, where the artifacts in question are clearly visible. The printing direction P is from left to right; the chains formed in the image are evident at this magnification and will be perceptible at normal viewing distances. Figure 6 shows a similar printed image at higher magnification showing the horizontally extending chains in more detail. Figure 7 A print image showing the same print data as in FIG. 6, which is printed according to the present invention. The effect of using the present invention is clearly visible, the merging of droplets is now substantially isotropic, thus eliminating chain artifacts.

[0039] Figures 8 and 9 show, respectively, the theoretical droplet deposition for a single nozzle (N1) printing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com