Infrared image defect identification method of principal component-morphology-watershed edge operator

An infrared image and edge operator technology, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of infrared image noise interference and unclear image boundaries, so as to reduce noise interference and reduce a large number of redundant boundaries. , Improve the effect of defect recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A principal component-morphology-watershed edge operator infrared image defect recognition method, the method includes the following steps:

[0040] Step 1: First input the infrared image and create its structural elements, and then decompose the structural elements;

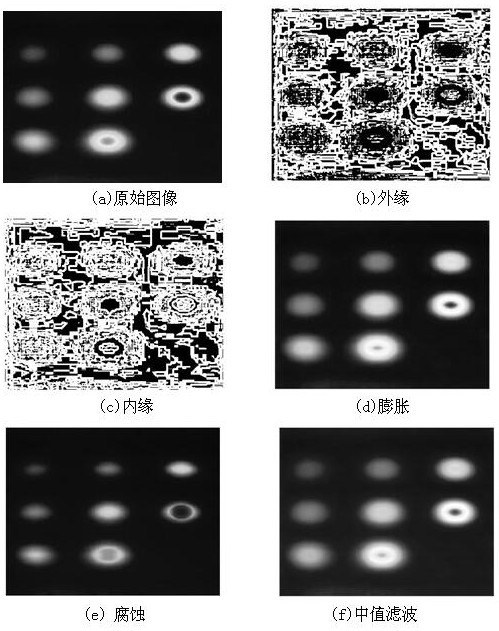

[0041] Step 2: Carry out expansion and erosion operations respectively, then set the number of principal components, and establish a covariance matrix;

[0042] Step 3: Calculate its eigenvalue and corresponding eigenvector, and use the eigenvalue to calculate the cumulative contribution rate;

[0043] Step 4: Determine whether to calculate the outer edge of the defect and the inner edge of the defect according to the cumulative contribution rate;

[0044] Step 5: If the cumulative contribution rate is less than 80%, increase the number of principal components and repeat the above process; if the cumulative contribution rate is ≥80%, reconstruct the morphological gradient matrix, and simultaneously calcu...

Embodiment 2

[0051] According to the principle component-morphology-watershed edge operator infrared image defect recognition method described in embodiment 1, the specific process of the first step is: input the infrared image, create a structural element, and the shape of the structural element has a square, a rectangle And rhombus, etc., and then decompose the structural elements to improve execution efficiency, and perform expansion and erosion processing respectively. The definition is as follows:

[0052] (1)

[0053] (2)

Embodiment 3

[0055] According to the principal component-morphology-infrared image defect recognition method of the watershed edge operator described in embodiment 1 or 2, the specific process of the second step is: set the number of principal components, and standardize at the same time, so that the mean is 0, the standard deviation is 1, the covariance matrix is established, and the eigenvalues are calculated and the corresponding eigenvectors , using the eigenvalues for the cumulative contribution rate The judgment is as follows:

[0056] (3)

[0057] (4)

[0058] The concrete process of described step five is:

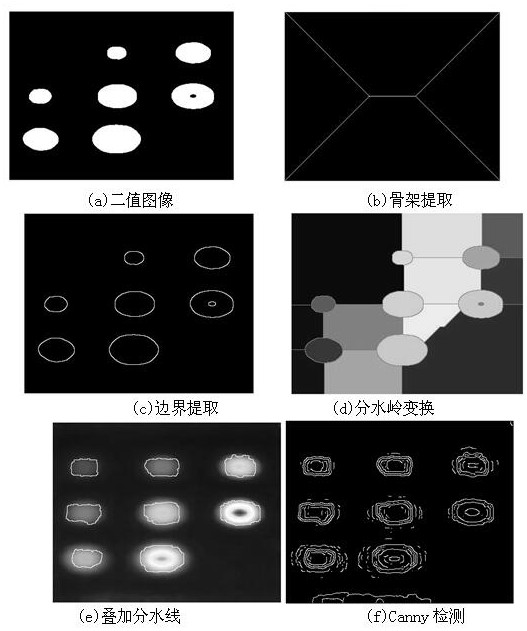

[0059] According to the cumulative contribution rate Determine whether to calculate the outer edge of the defect and the inner edge of the defect, if the cumulative contribution rate ≥80%, reconstruct the morphological gradient ng(i,j) and simultaneously calculate the outer edge of the defect and the inner edge of the defect,

[0060] Calculate the defec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com