Online automatic optical detection image retrieval method

An automatic optical detection and image retrieval technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of false positives and false negatives, reduce the amount of calculation, improve the speed of calculation, reduce the rate of false positives and false positives. The effect of reporting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

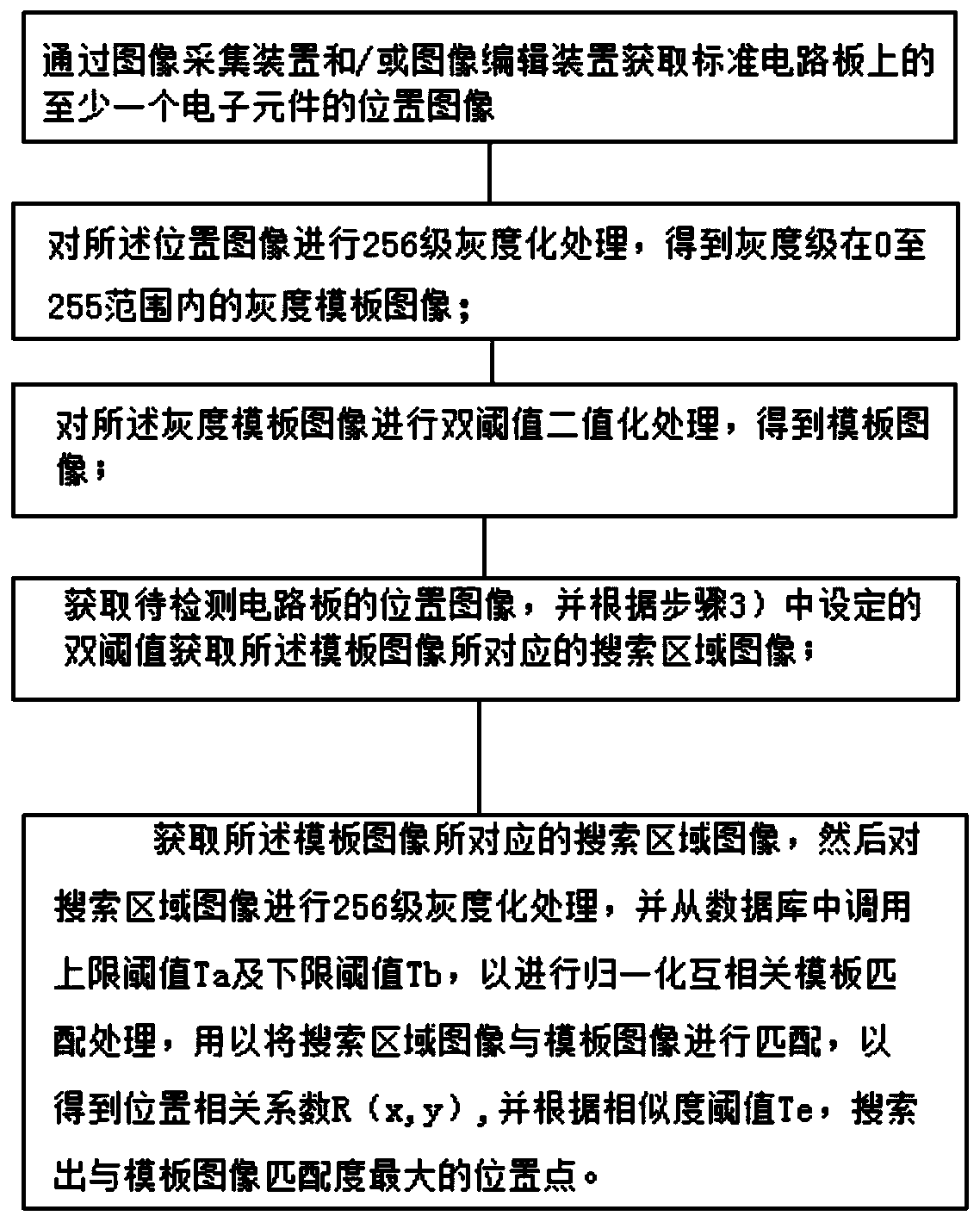

[0017] Such as figure 1 As shown, the embodiment of the present invention discloses an online automatic optical detection image retrieval method, including the following steps:

[0018] 1) Obtain a positional image of at least one electronic component on the standard circuit board through an image acquisition device and / or an image editing device;

[0019] 2) performing 256-level grayscale processing on the position image to obtain a grayscale template image with a grayscale within the range of 0 to 255;

[0020] 3) performing double-threshold binarization processing on the grayscale template image to obtain a template image;

[0021] 4) Obtain the position image of the circuit board to be detected, and obtain the search area image corresponding to the template image according to the double threshold set in step 3);

[0022] 5) Obtain the search area image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com