Production method of shoe heel steel pipe

A manufacturing method and technology for steel pipes, applied in the field of manufacturing heel steel pipes, can solve the problems of waste of strips, high cost of molds, difficult to estimate mold costs, etc., and achieve the effects of increasing production capacity, reducing costs, and reducing the number of specifications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

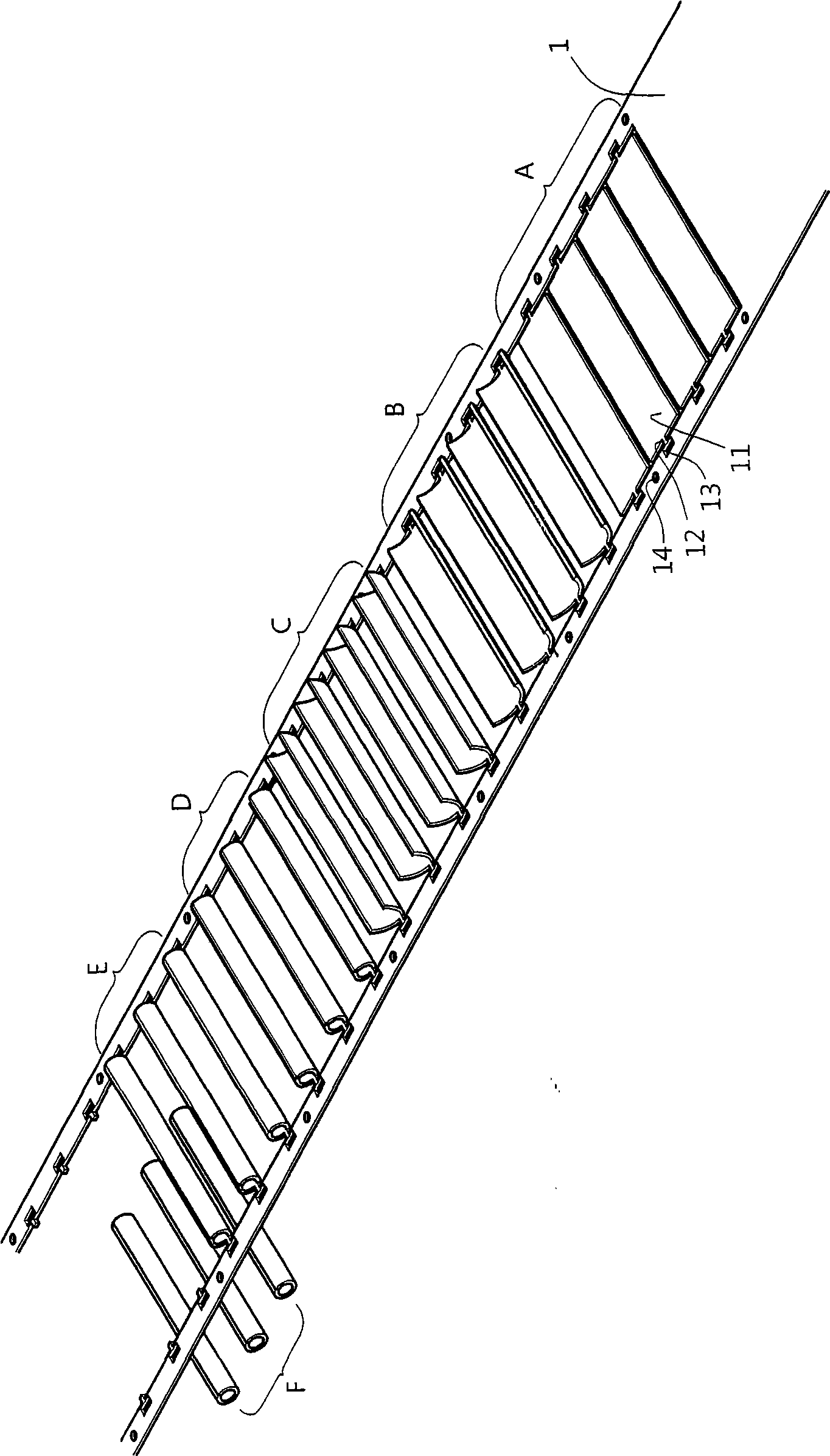

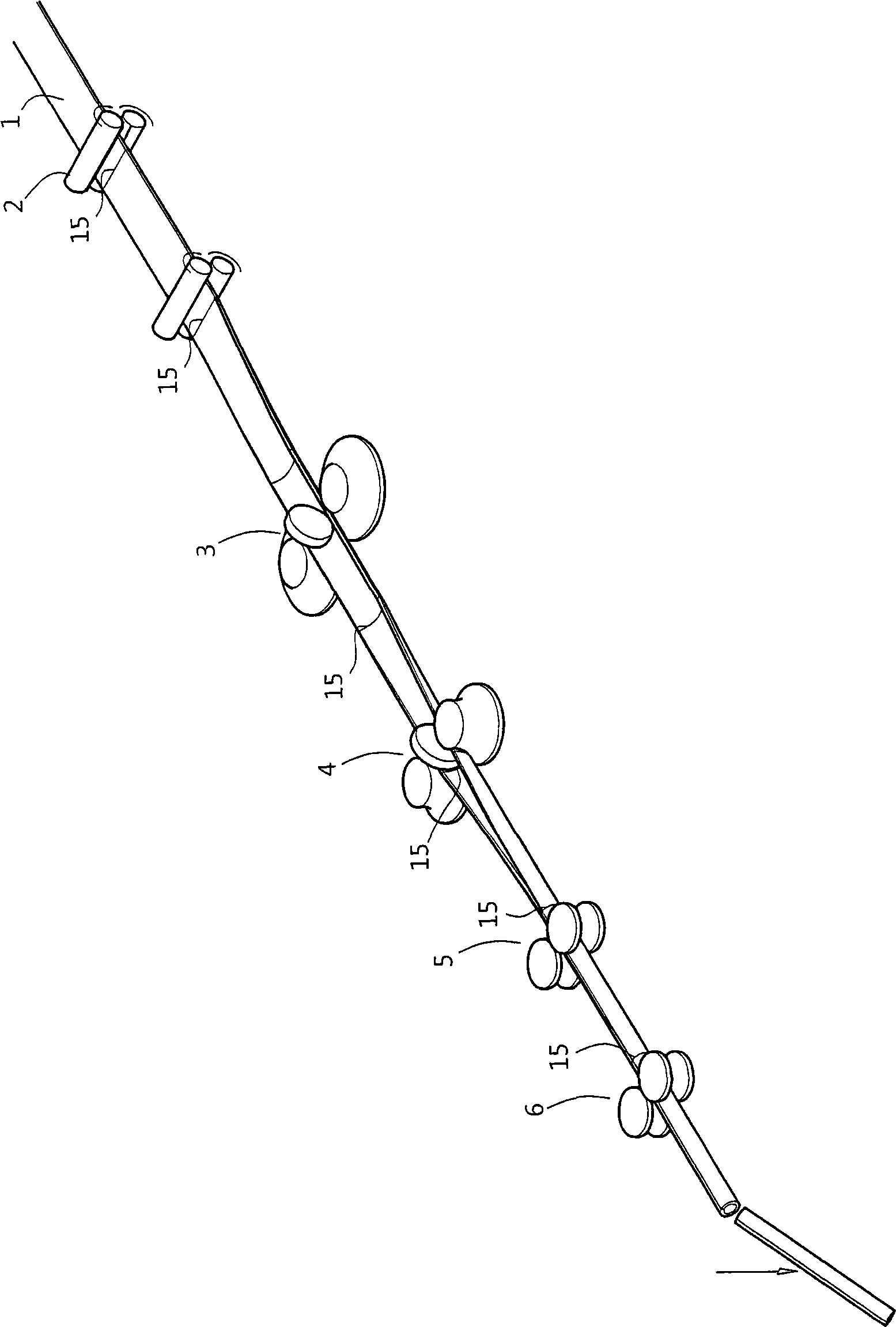

[0018] Please refer to image 3 As shown, the present invention is a method for continuous rolling and rolling of steel pipes. The steps are to send the strip 1 to the shearing and pressing wheel 2 via the conveying wheel, and perform the shearing and pressing process of the fracture mark 15, and each formed fracture The distance between the marks 15 is the length of the steel pipe to be made, and then the strip 1 is continuously conveyed to pass through the first rolling wheel set 3 (such as Figure 4 As shown), the strip 1 is bent into a predetermined arc-shaped prototype, and then passed through the second rolling wheel set 4 (such as Figure 5 As shown), the strip 1 of the arc-shaped prototype is bent into a semi-elliptical shape again, and then continues to pass through the third rolling wheel set 5 (such as Image 6 As shown), the semi-elliptical strip 1 is rolled into a nearly circular pipe, and then continues to pass through the fourth rolling wheel set 6 (such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com