A modular water jet propulsion steering and reversing mechanism

A water-jet propulsion, modular technology, applied in the direction of steering with jets, steering gear, ship parts, etc., can solve the problems of increasing the risk of operating vibration of the water-jet propulsion device, scrap of guide vane castings, etc., to shorten the installation time. The effect of reducing disassembly time, reducing vibration risk and improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

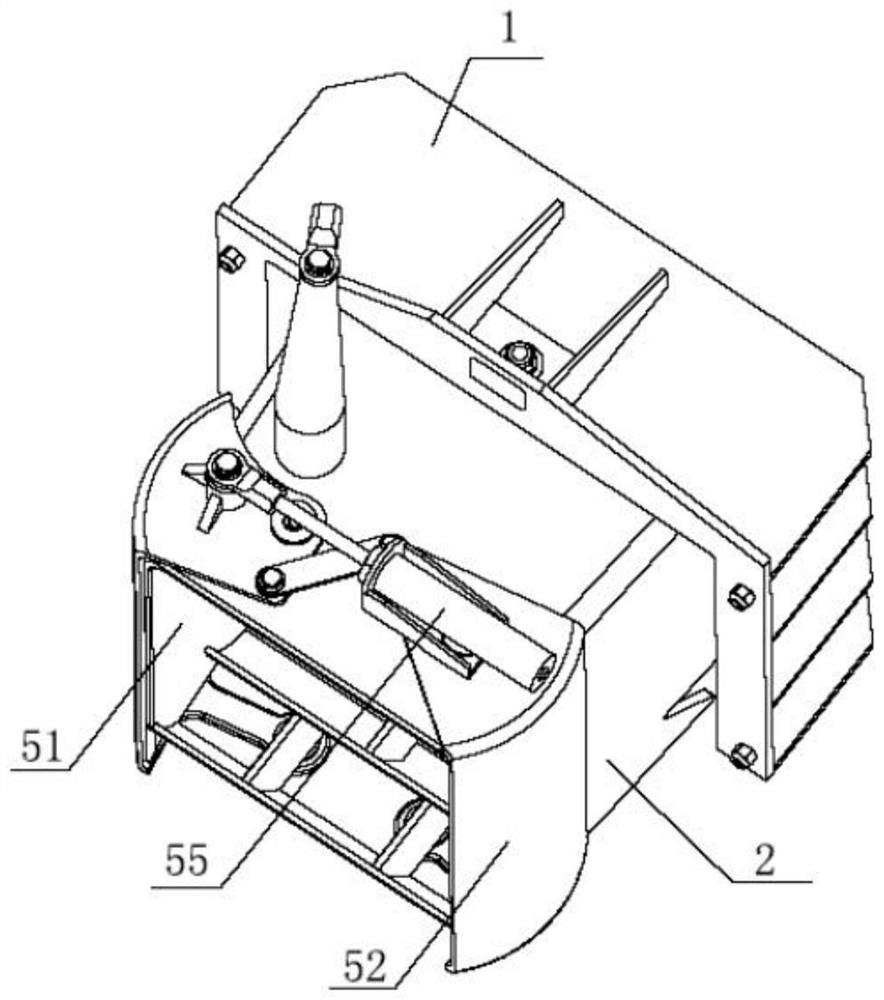

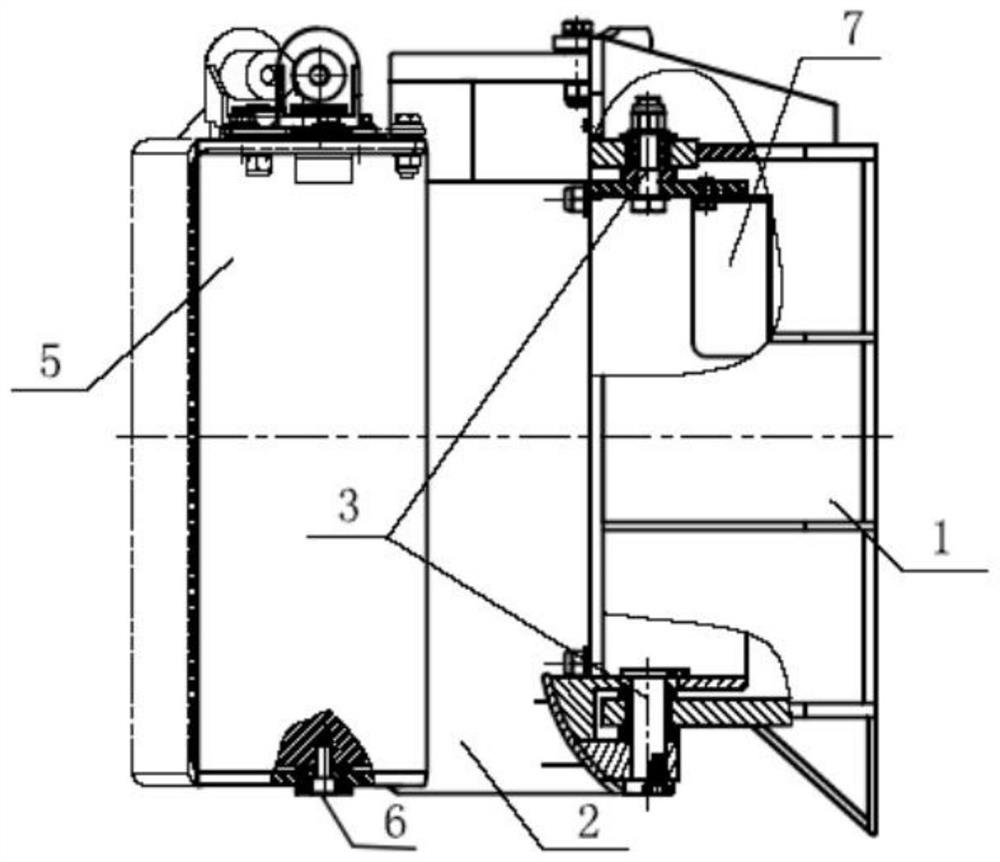

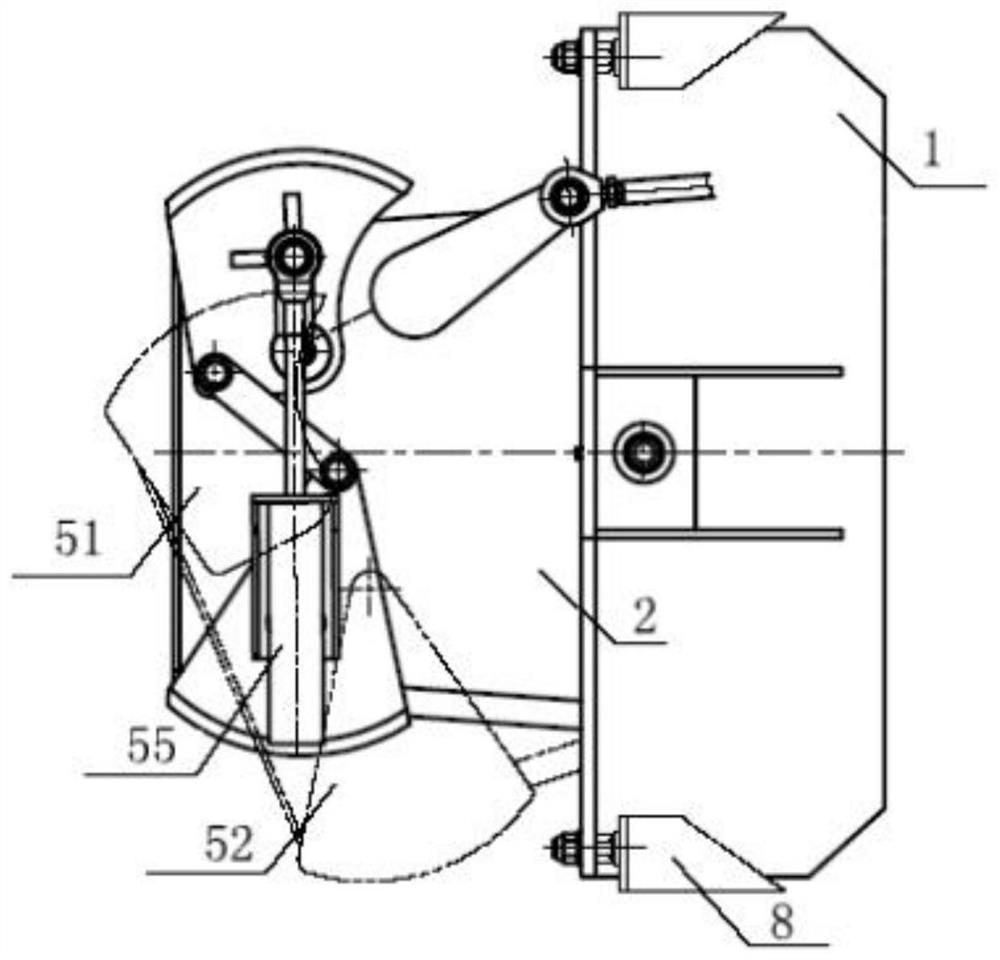

[0037] In the preferred embodiment of the present invention, based on the current situation that the water-jet propulsion steering and reversing mechanism has various specifications, the interface with the water-jet propulsion pump is complicated, and the assembly and disassembly are difficult, a modular water-jet propulsion mechanism is now provided. Steering reversing mechanism, such as figure 1 , figure 2 and image 3 shown, including:

[0038] The steering reversing mechanism bracket 1 is used to fix the water jet propulsion steering reversing mechanism;

[0039] The rudder 2 is connected to the steering reversing mechanism bracket 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com