A device and method for cutting and collecting the tail shank of the steel wire screw sleeve of the complex blind cavity receiver

A technology of wire thread sleeves and tail handles, which is applied in the field of devices for cutting and collecting wire thread sleeve tail handles in aluminum-magnesium alloy casings and other types of casings, and can solve problems such as polluted parts, wire thread sleeve scrapping, and low work efficiency. Achieve convenient use and management, reduce the number of parts, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

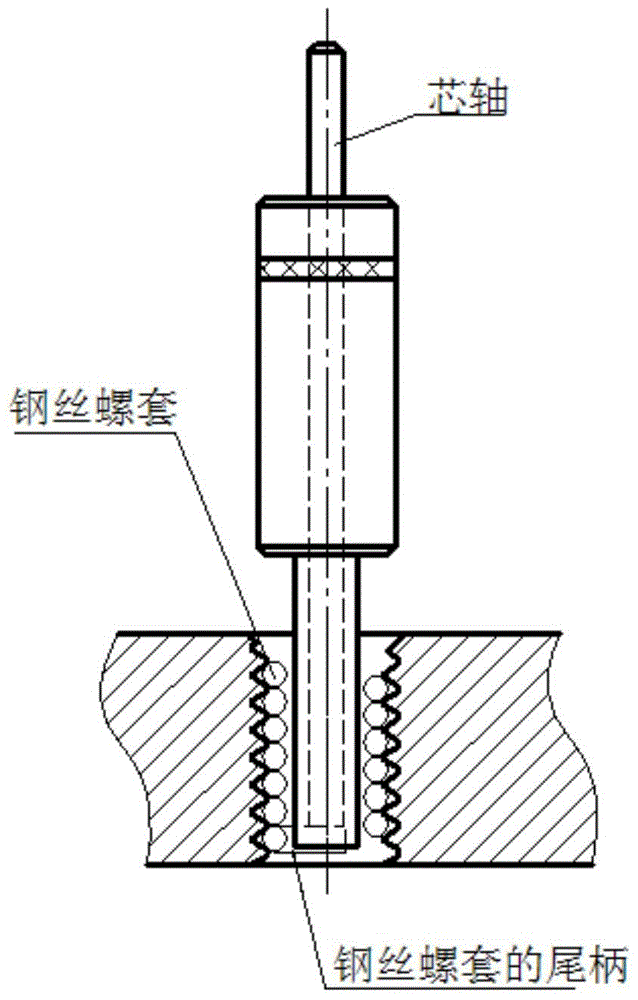

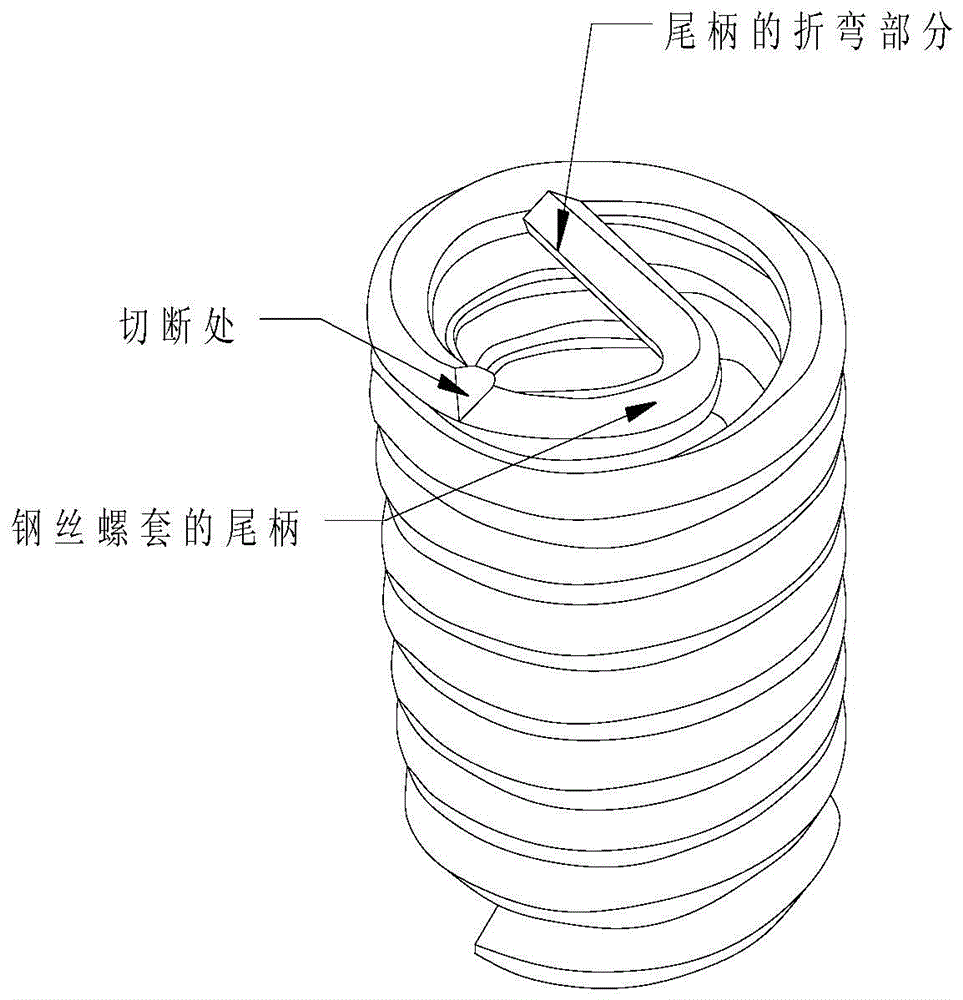

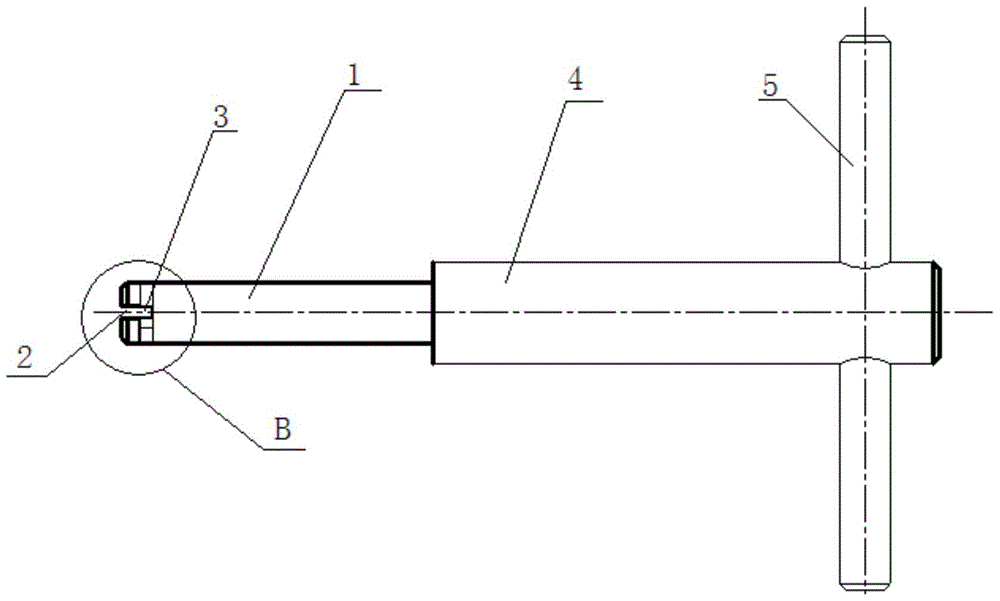

[0041] Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a device for cutting off and collecting the tail handle of the wire screw sleeve of the complex blind cavity casing includes a connecting rod 4, a handle rod 5 and a guide mandrel 1 that can be inserted into the inner hole of the wire screw sleeve. The guide mandrel The cross-sectional shape of 1 is circular, and the diameter of the guide mandrel 1 is smaller than the minimum inner diameter of the inner hole of the wire screw sleeve; the end of one end of the guide mandrel 1 is provided with a groove A 2 inwardly along the length direction of the guide mandrel 1, and the After the guide mandrel 1 is inserted into the inner hole of the wire screw sleeve, the bent part of the tail handle of the wire screw sleeve can enter the groove A2 along the opening of the groove A2, and the width of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com