Extension shaft guide used for lifting counter level in mine shaft

A technology of intermediate level and telescopic tanks, which is applied to the lifting equipment, elevators, transportation and packaging in mines, and can solve the problems of lifting containers through at full speed and affecting lifting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

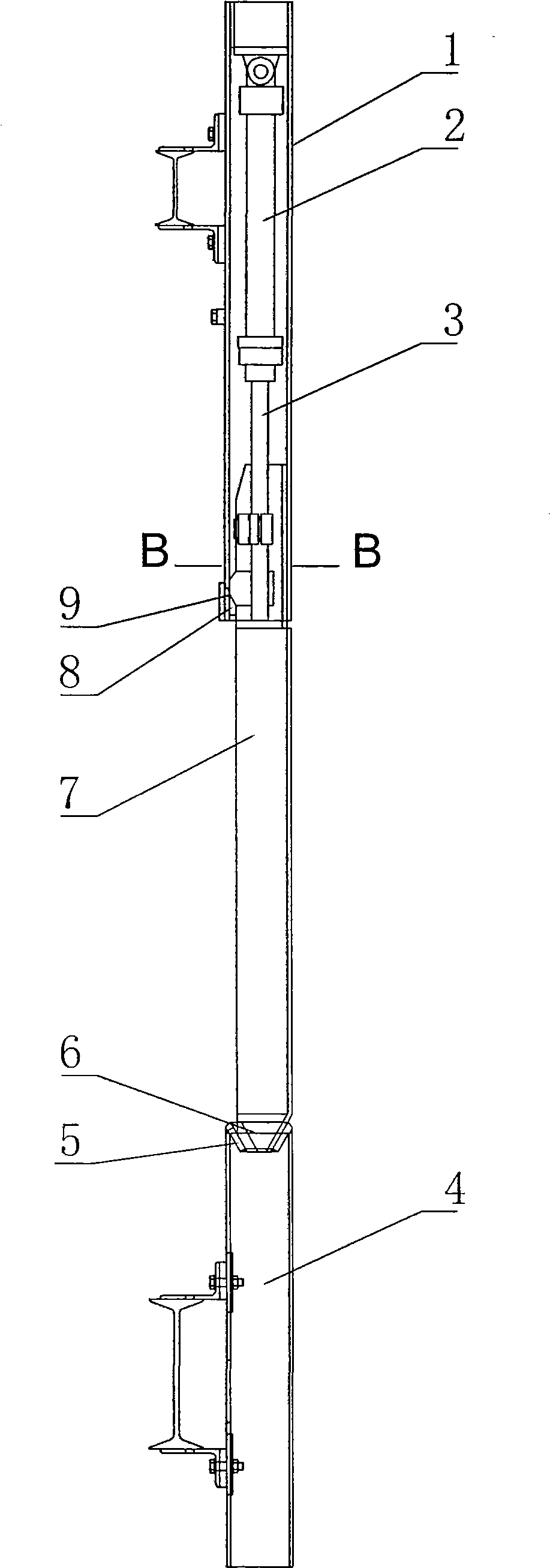

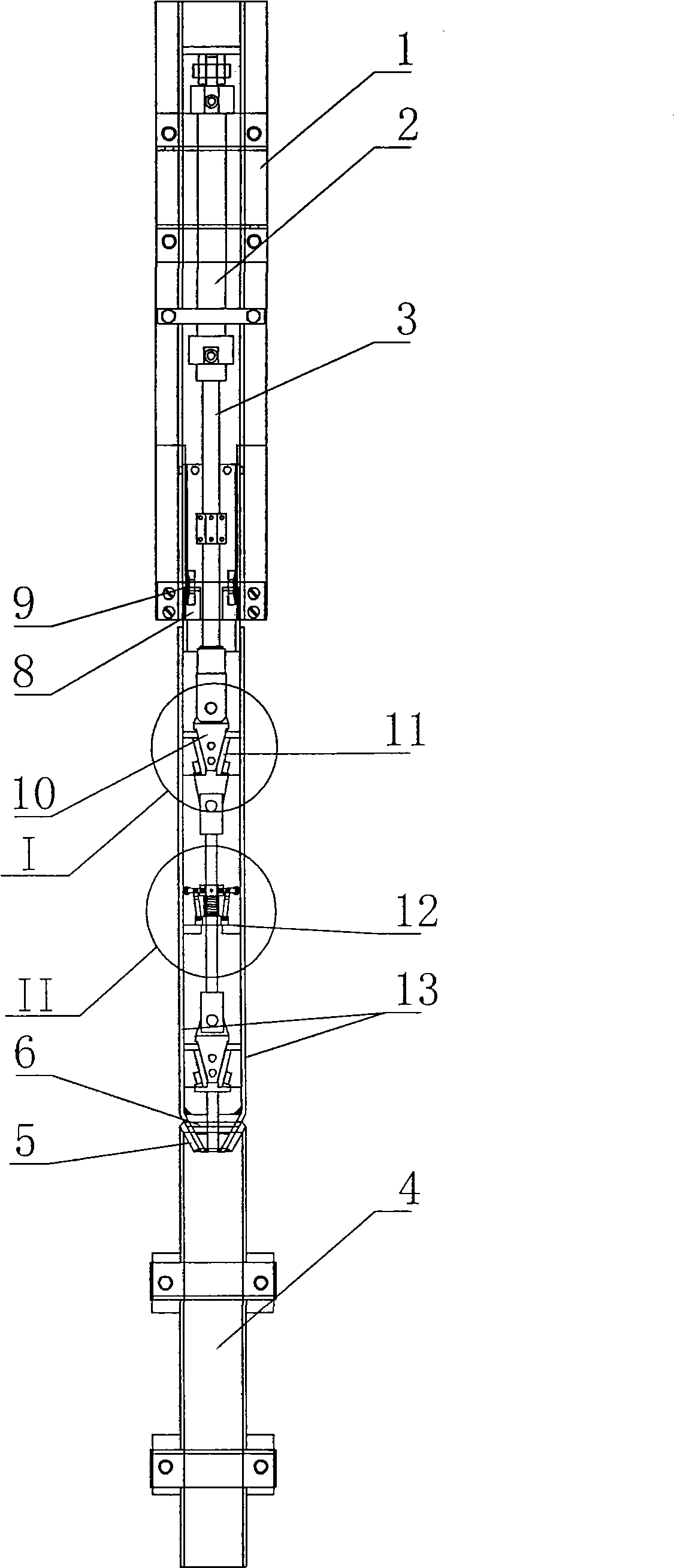

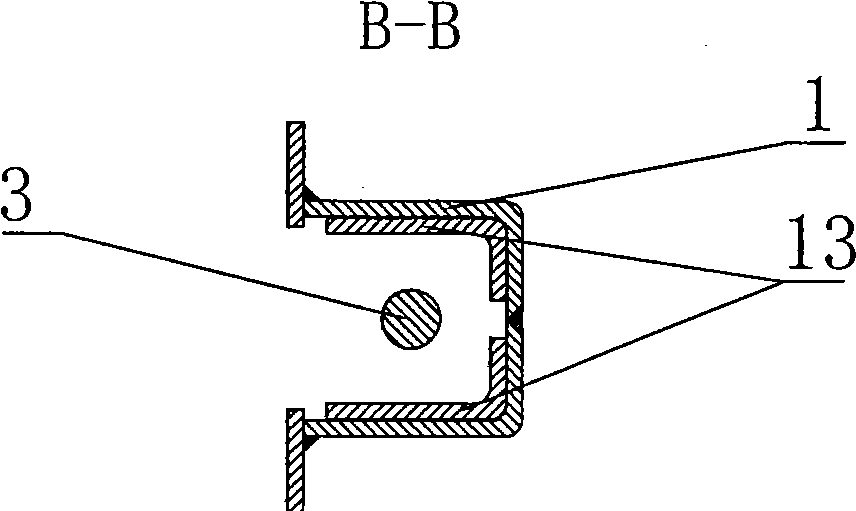

[0015] As shown in the figure, the telescopic tank for lifting the middle level of the mine shaft includes an upper fixed tank 1 and a lower fixed tank 4 arranged on the same axis. The upper fixed tank 1 is sleeved with a movable tank 7, and the upper fixed tank There is an oil cylinder 2 inside the tank road 1, the upper end of the oil cylinder 2 is fixed in the upper fixed tank road 1, the piston rod 3 of the oil cylinder 2 protrudes from the lower end of the oil cylinder 2, and the protruding end of the piston rod 3 is connected with the upper end of the movable tank road 7 When the piston rod 3 is stretched out, the movable canister 7 will connect the upper fixed canister 1 and the lower fixed canister 4. The upper end surface of the lower fixed tank path 4 is provided with a card slot 5, and the lower end surface of the movable tank channel 7 is provided with a protrusion 6 matching the card slot 5, and the upper fixed tank channel 1 and the lower fixed tank channel 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com