Large recombined decorative composite floor plate and production method thereof

A technology for reorganizing decoration and composite flooring, which is applied in the jointing of wooden veneers, manufacturing tools, and the manufacture of thin wood chips, etc. It can solve problems such as the shortage of natural and precious wood resources, and achieve precious and unique decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

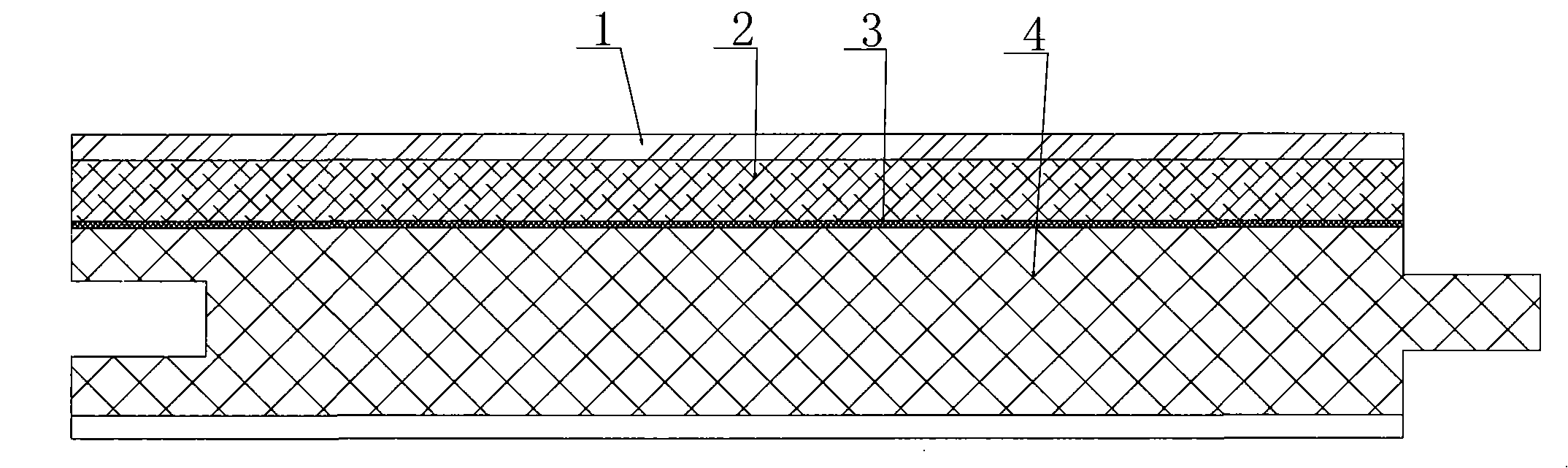

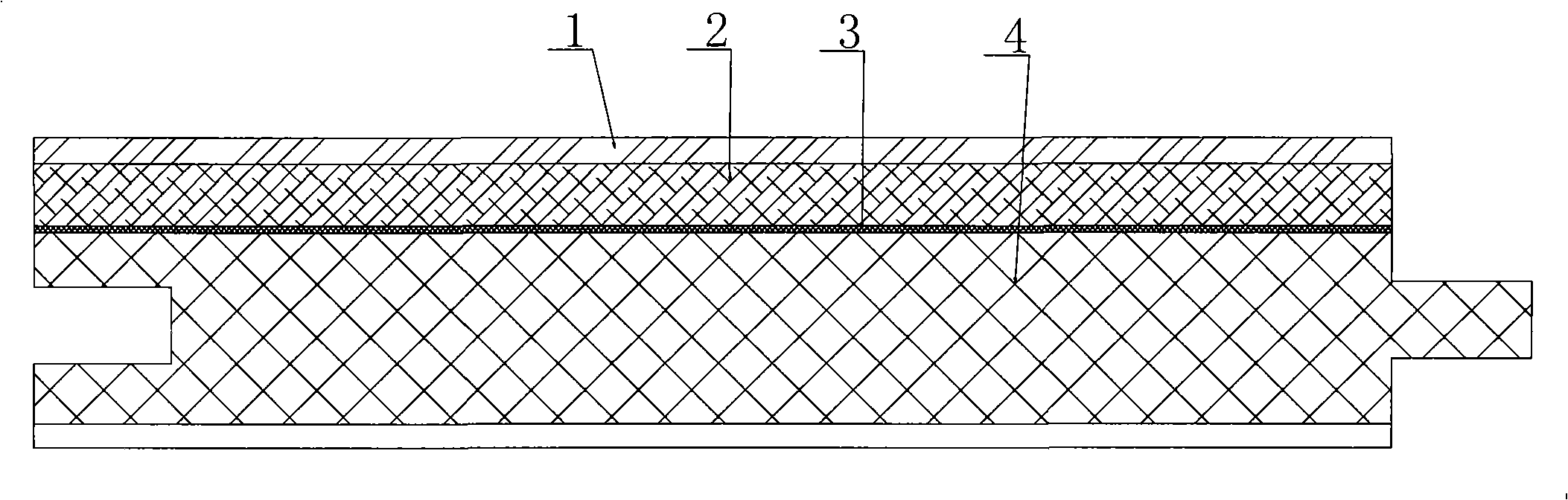

[0022] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 The large-format recombined decorative veneer composite floor and its manufacturing method are shown. The composite floor includes a surface transparent wear-resistant layer 1 , a surface layer 2 and a substrate layer 4 . The surface transparent wear-resistant layer 1 is made of paint and arranged on the surface of the surface layer 2. The base plate is made of plywood, solid wood strips or solid wood strips combined with the bottom veneer. The surface layer 2 and the base layer 4 are bonded by an adhesive 3. The surface layer 2 is made of reconstituted decorative material panels, which are obtained by cutting reconstituted decorative materials, with a single format and surface imitating wood grain of precious wood, with a width of 16-36 cm, a length of 100-300 cm, and a thickness of 2-3 cm. 6mm.

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com