Continuously variable transmission

A technology of transmission and stepless speed change, which is applied in the direction of transmission, friction transmission, transmission control, etc. It can solve the problems of low energy efficiency rolling parts wear and excessive size, and achieve the effect of simplified coordinated control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

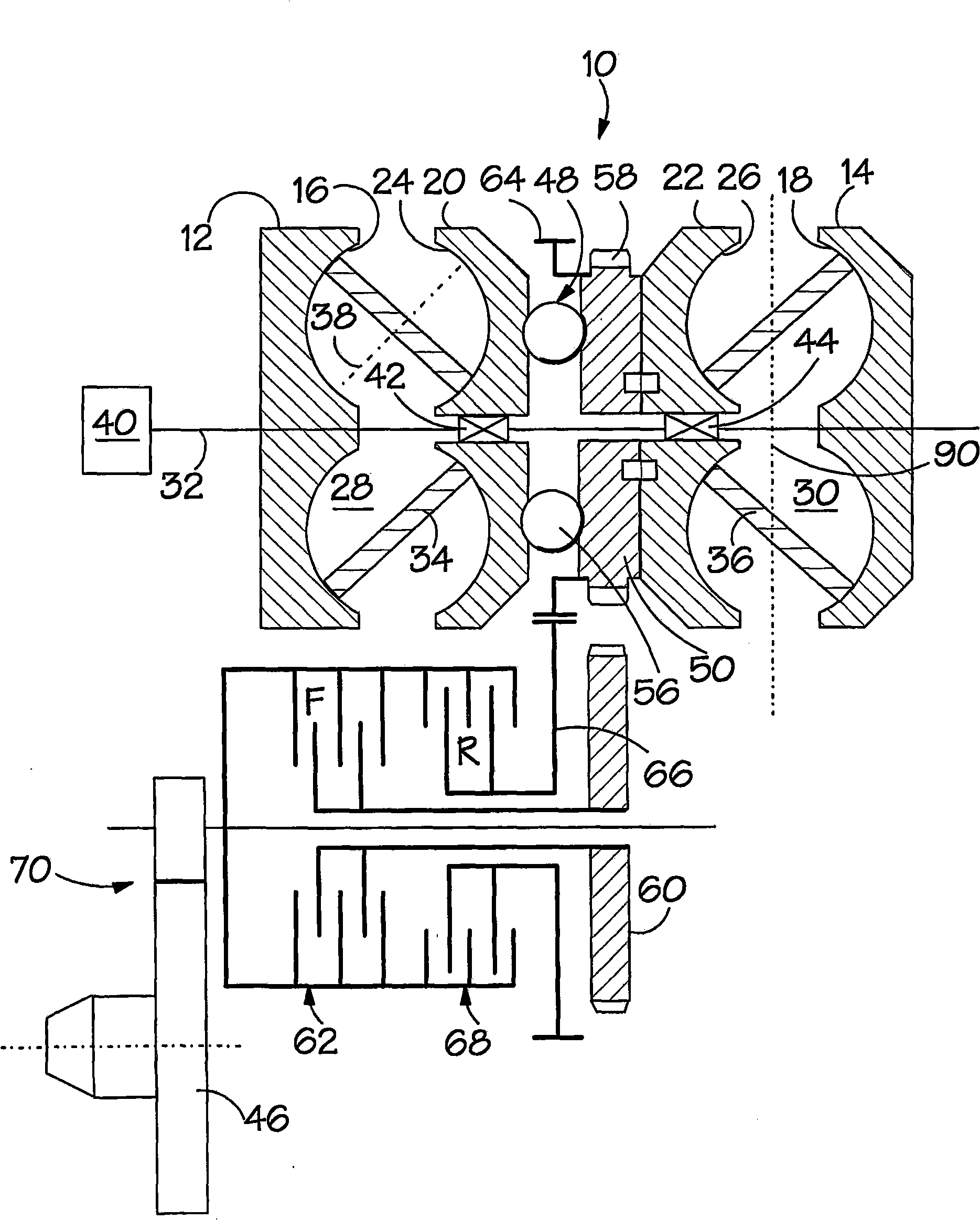

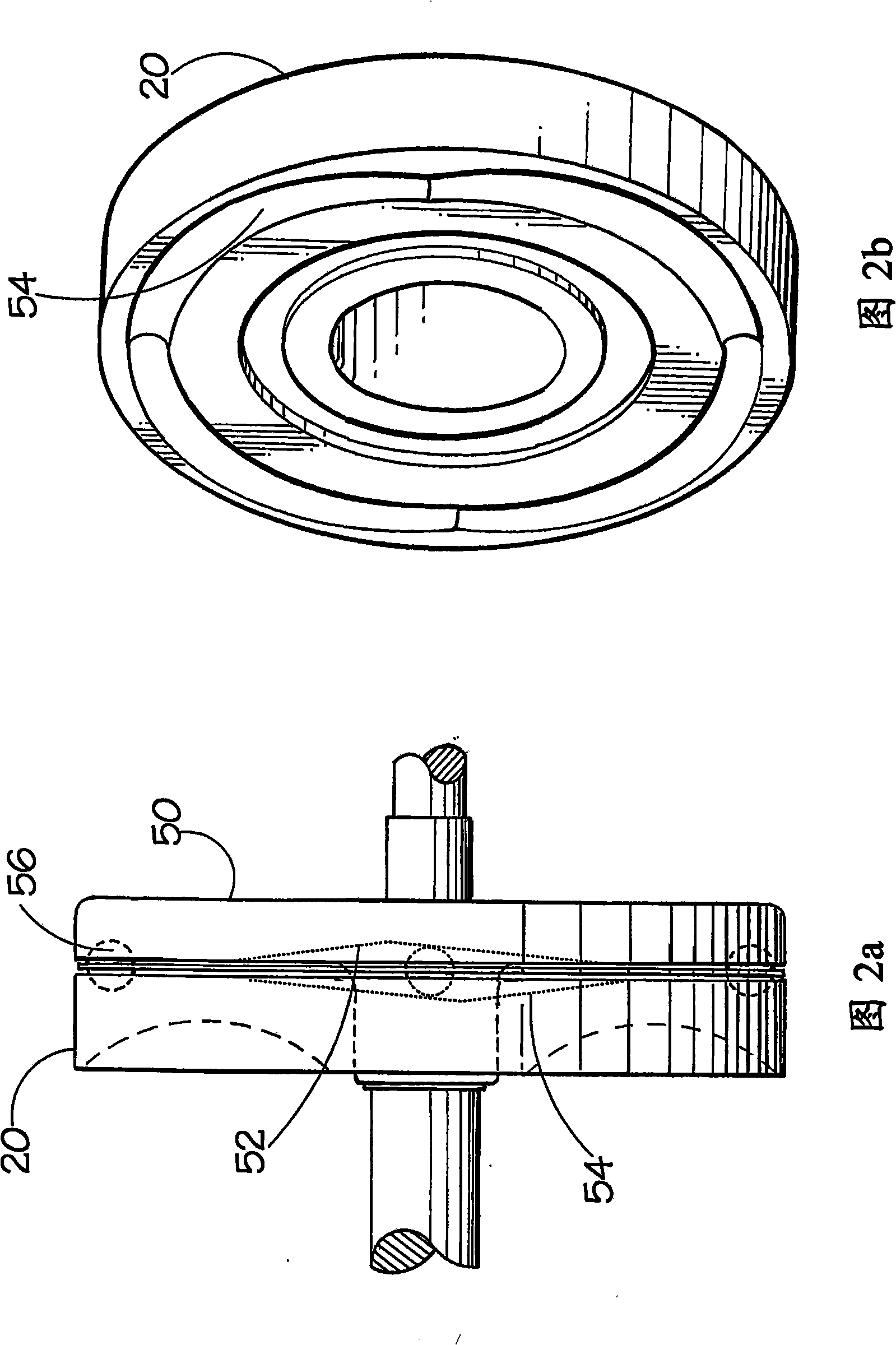

[0023] figure 1 A CVT using a toroidal raceway rolling traction type transmission 10 is shown. More specifically, this is a two-chamber full toroidal variator. The variator has a first input race 12 and a second input race 14 with respective semi-annular concave surfaces 16 , 18 . Between these input races are a first output race 20 and a second output race 22, and these two races also have respective semi-circular concave surfaces 24, 26 so that A first annular cavity 28 is formed between 12 and the first output raceway 20 , and a second annular cavity 30 is formed between the second input raceway 14 and the second output raceway 22 . These raceways have a common axis of rotation defined by a main shaft (schematically indicated at 32 ) around which they turn.

[0024] Each cavity 28 , 30 contains a respective roller set 34 , 36 . Each roller is mounted for rotation about a roller axis such as 38, and each roller moves on the toroidal surfaces of its associated input and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com