Gluewater-defoaming device and defoaming method

A technology of glue and glue water pressure, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve the problems of unavoidable, difficult, and unequal mixing ratios, preventing the entry of outside air, and the structure of the device is simple. , to meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

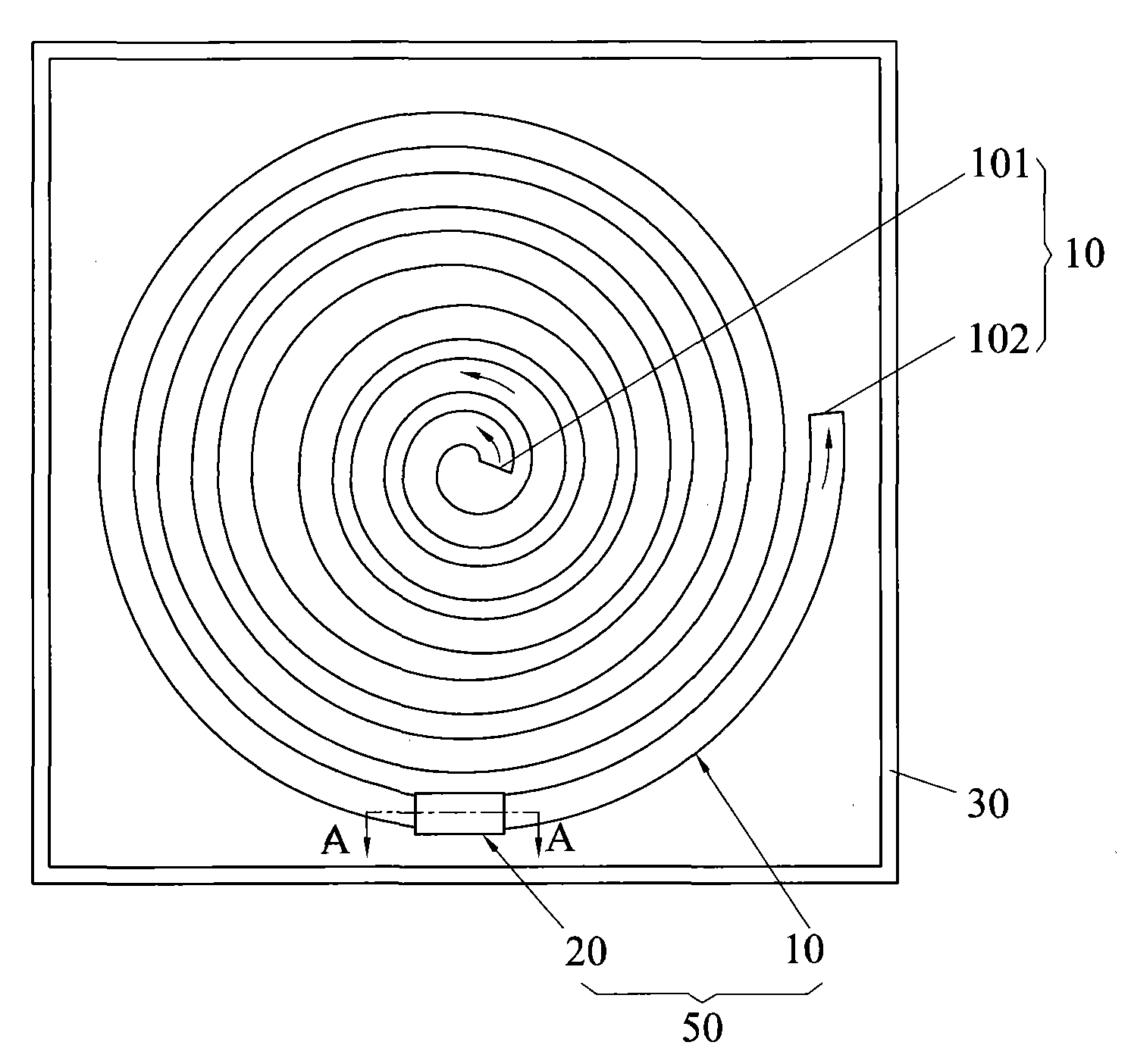

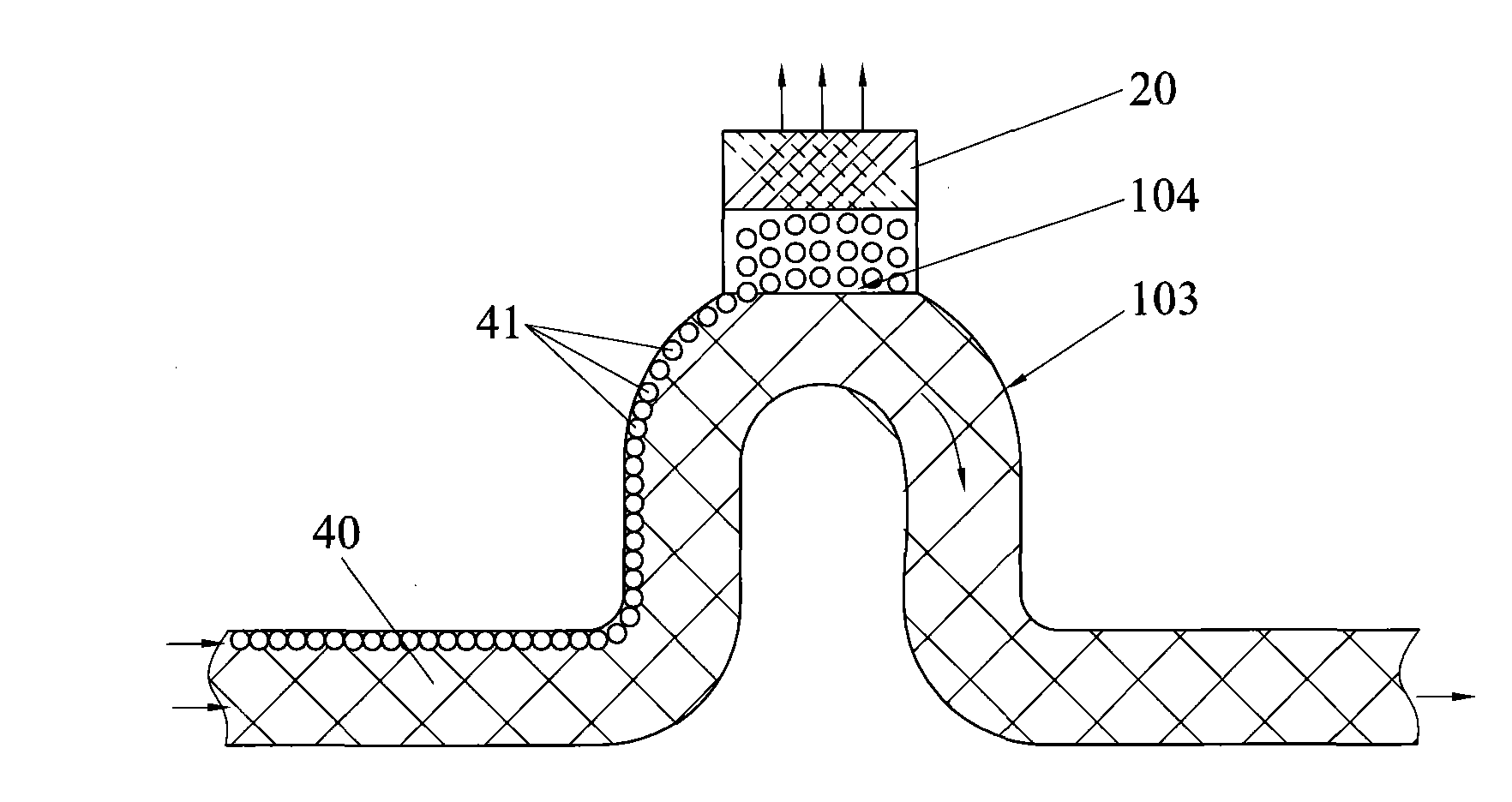

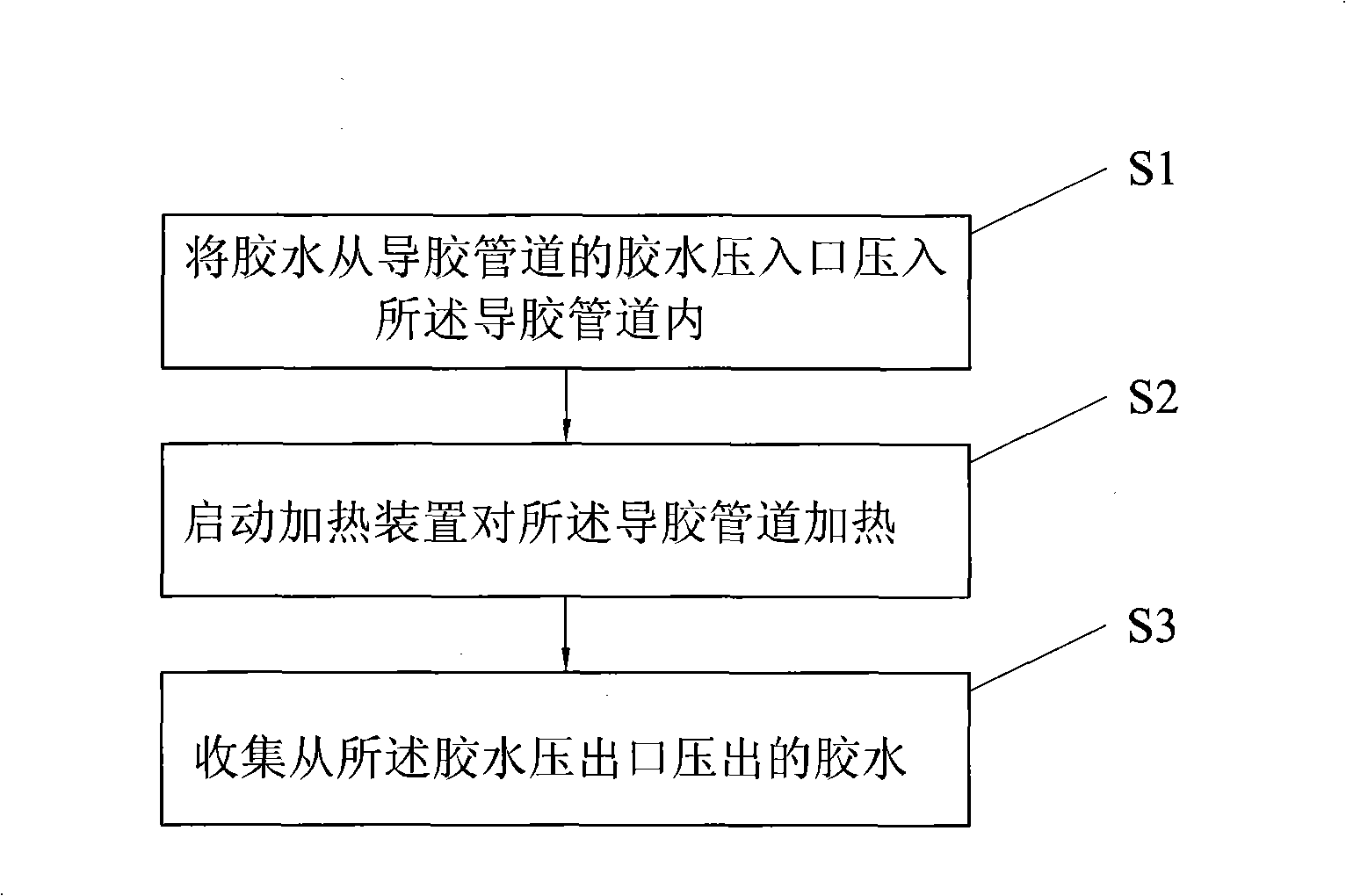

[0018] Such as figure 1 and figure 2 As shown, the glue defoaming device of the present invention includes a heating device (not shown) and a container 30, the heating device is installed on the container 30, the heating device is electrically connected to the outside, and it also includes a defoaming device Mechanism 50, the defoaming mechanism 50 includes a glue guiding pipeline 10 and a filter device 20, the glue guiding pipeline 10 has a glue pressure inlet 101 and a glue pressure outlet 102, and the glue pressure outlet 102 end of the glue guiding pipeline 10 has a curved A raised arched circuit 103 is folded, and a foam discharge port 104 is opened on the raised arched circuit 103, and the filter device 20 is arranged at the foam discharge port 104 of the raised arched circuit 103, The glue guiding pipe 10 is acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com