Dressing machine having double straining boxes

A technology for sieving box and grain cleaning, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of vibration of the machine body, affecting the service life of the machine, unable to achieve accurate classification of grain, etc., to improve the service life and good balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

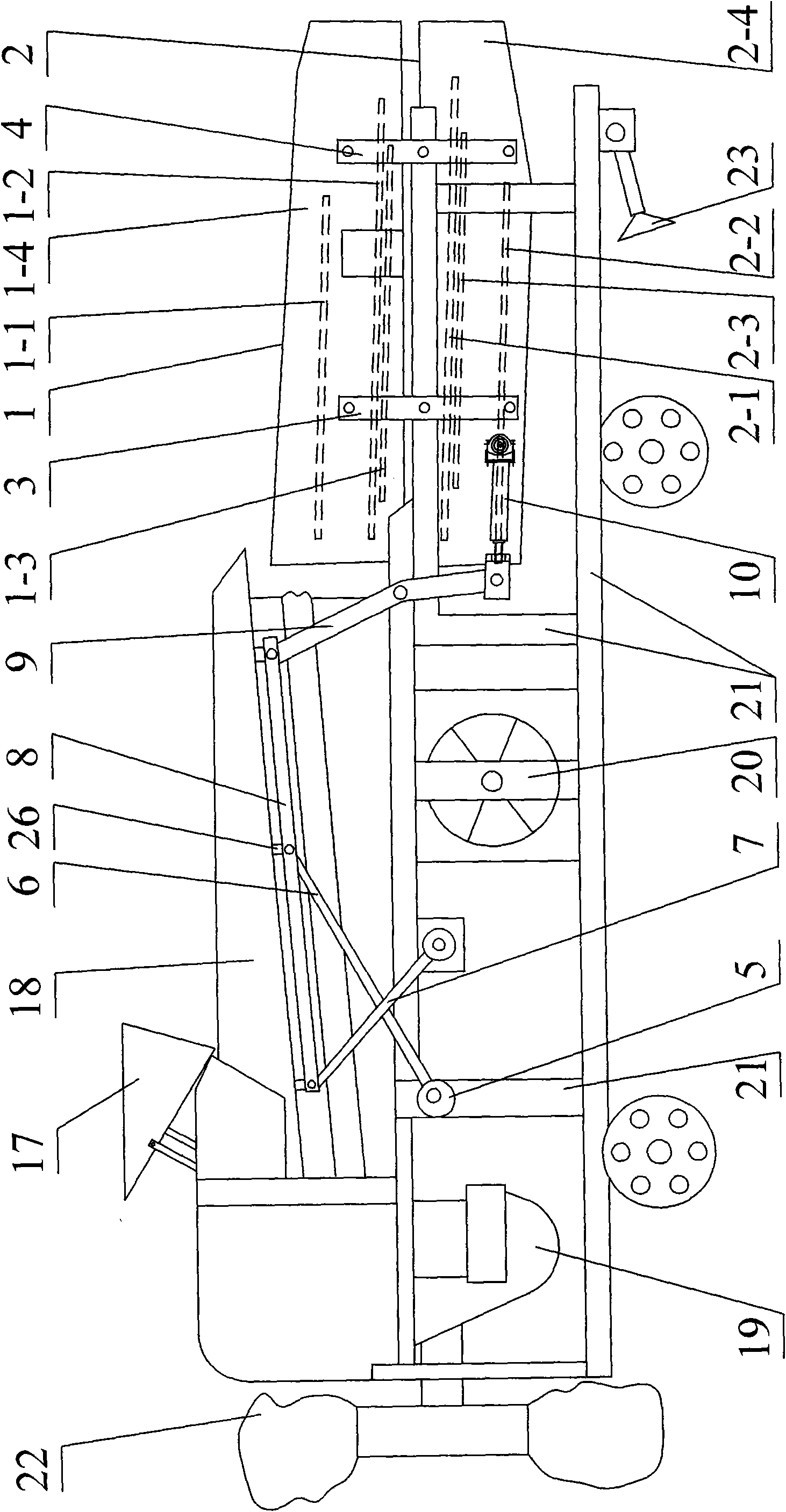

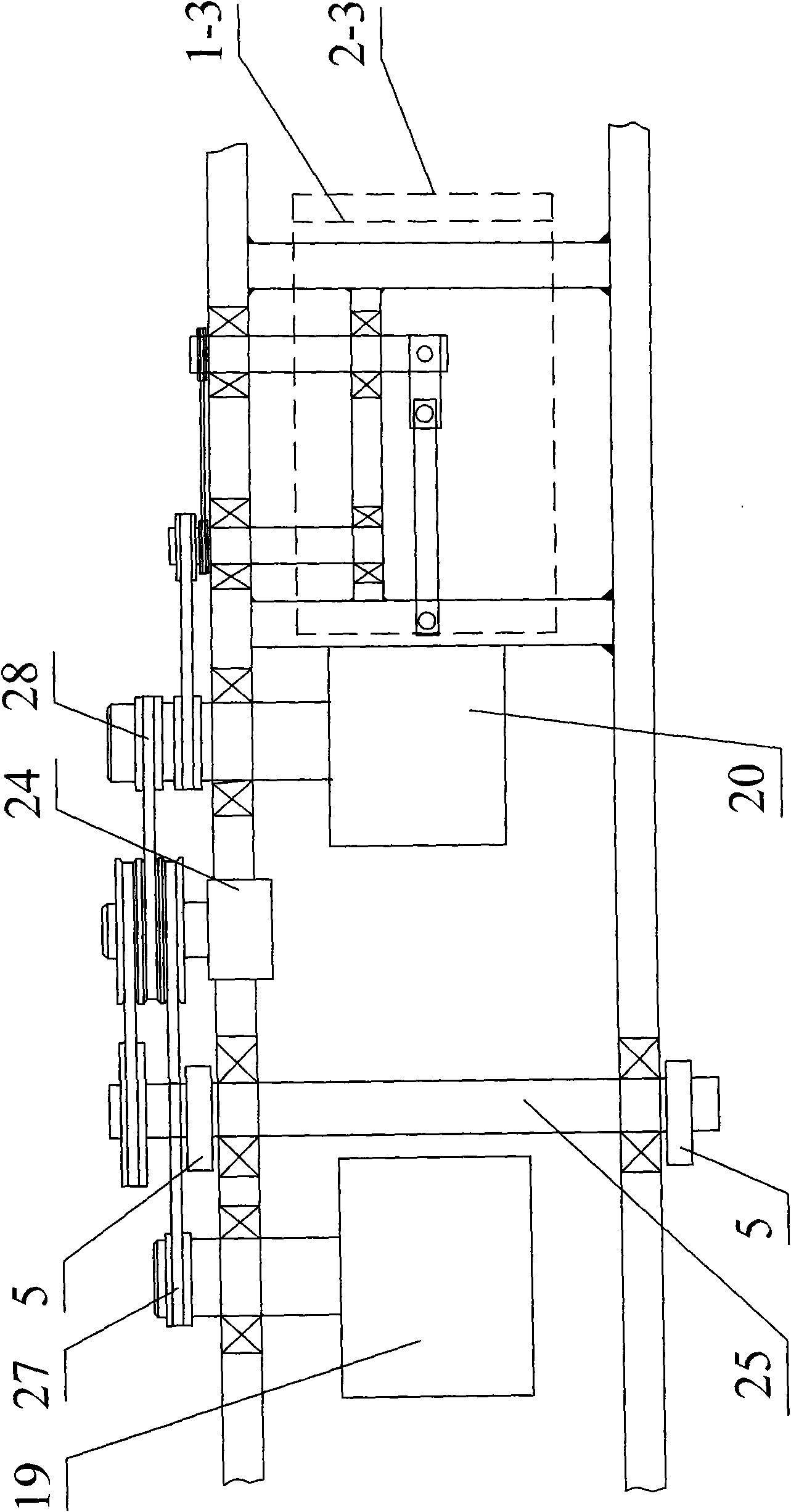

[0007] Specific implementation mode one: as figure 1 and figure 2 As shown, the grain cleaning machine with double sieve boxes in this embodiment includes a frame 21, a grain feeding container 17, a specific gravity box 18, an induced draft fan 19, a blower 20, a motor 24, an induced draft fan transmission mechanism 27 and a blower transmission mechanism 28. The specific gravity box 18 is installed on the frame 21, and the grain feeding container 17 is arranged on the upper end of the specific gravity box 18. The induced draft fan 19 and the blower 20 are respectively driven by the output shaft of the induced draft fan transmission mechanism 27, the blower transmission mechanism 28 and the motor 24. Connection, the induced draft fan 19 and the blower 20 are all located under the specific gravity box 18, the induced draft fan 19 is installed on the frame 21 and communicates with one end of the specific gravity box 18, and the blower fan 20 is installed on the frame 21 and conn...

specific Embodiment approach 2

[0009] Specific implementation mode two: as figure 1 and figure 2 As shown, the fourth connecting rod 9 in this embodiment is a curved rod, and the bending point of the curved rod is hinged to the frame 21 at the corresponding position. The fourth connecting rod 9 is designed as a bent rod, and when the upper end of the fourth connecting rod 9 swings slightly, its lower end will swing at a larger angle. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: as figure 1 and figure 2 As shown, the upper screen box 1 described in this embodiment includes the first screen mesh 1-1 of the upper screen box, the second screen mesh 1-2 of the upper screen box and the screen body 1-4 of the upper screen box, and the first screen of the upper screen box The net 1-1 and the second screen cloth 1-2 of the upper screen box are installed in the screen body 1-4 of the upper screen box from top to bottom. There are two layers of sieves, which can improve the grain cleaning and grading effects of the present invention. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com