Ground stereoscopic discharge and mining method of coal bed methane

A coalbed methane and ground technology, applied in gas discharge, mining fluid, mining equipment, etc., can solve the problems of complex geological conditions, low reservoir permeability, poor overall benefit, etc. The effect of cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

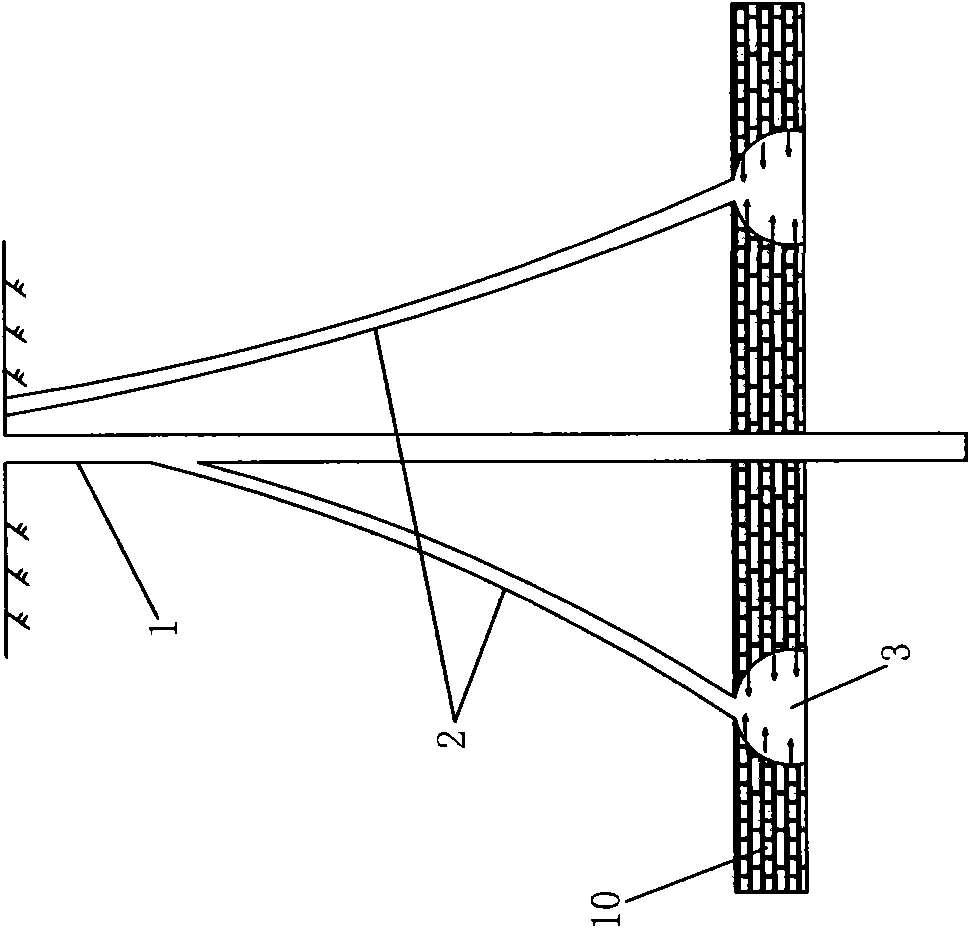

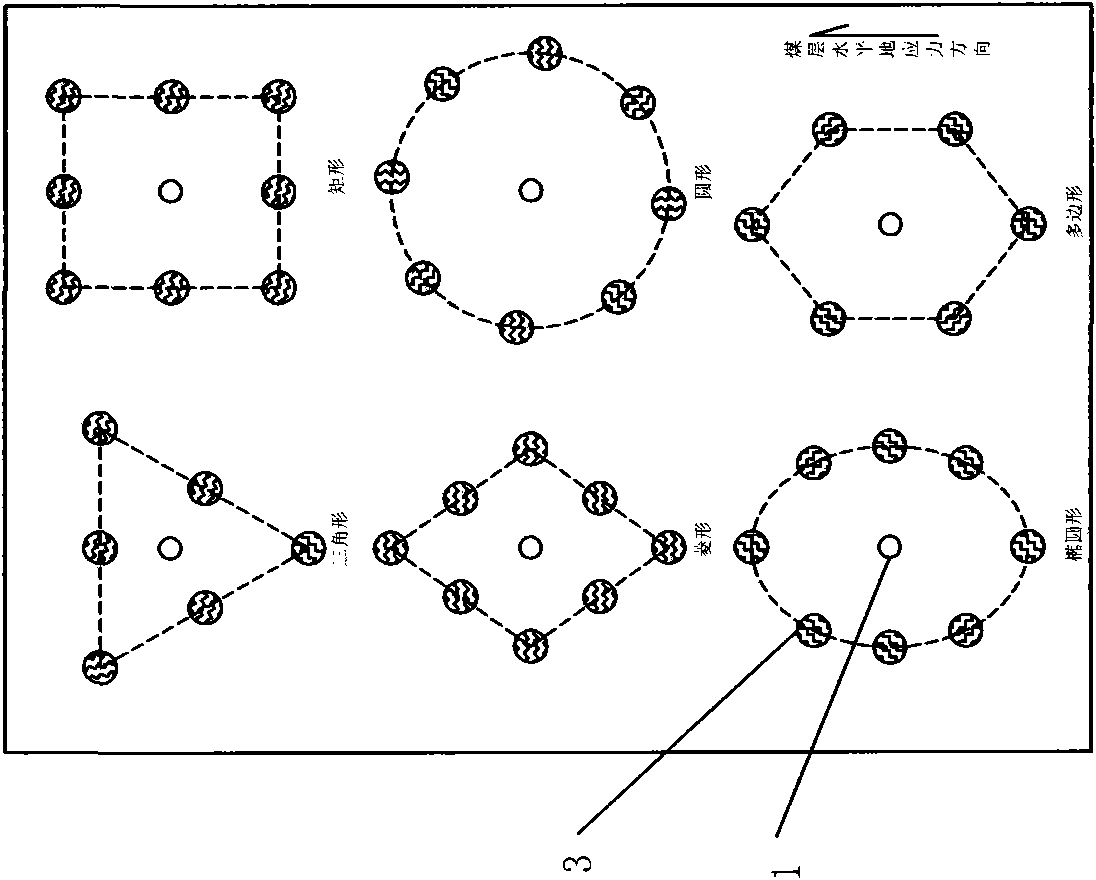

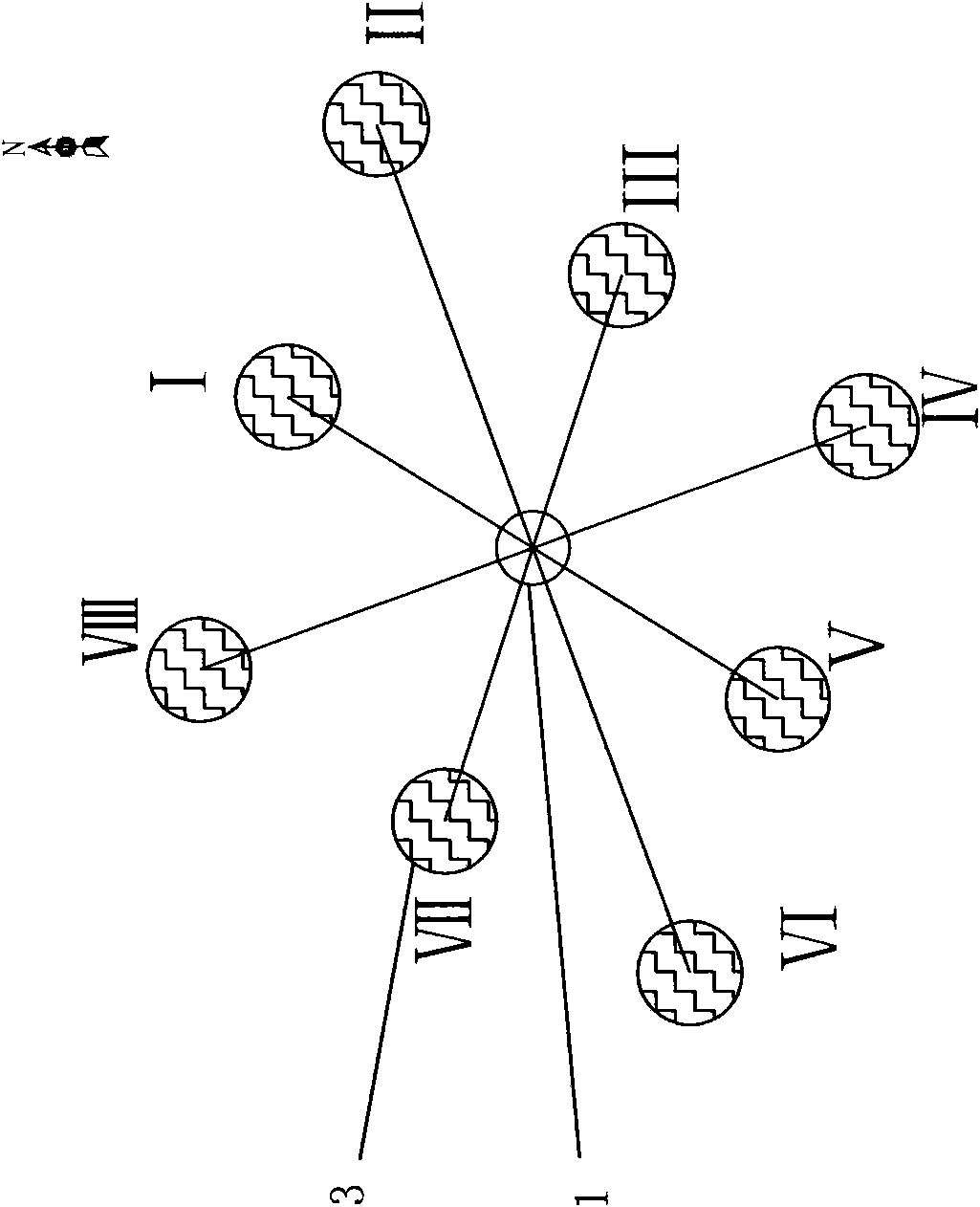

[0031] figure 1 Shown is a schematic diagram of the ground three-dimensional drainage of coalbed methane in the present invention. The three-dimensional ground drainage method of coalbed methane is to destroy the unconventional natural gas system that is formed over hundreds of millions of years of coal reservoirs (10), which is relatively independent and in equilibrium, breaks the equilibrium state of the system, makes it relatively homogeneous, and establishes a The new coal reservoir system that is conducive to drainage adopts the main well for drainage. In the coal seam around the main shaft (1), build a plurality of caves (3) (hereinafter referred to as "caves" for short) by directional inclined shafts (2) to form a coal seam stress concentration zone; During the process, the stress of the coal seam is released, which is beneficial to the desorption and seepag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com