Apparatus for inspecting honeycomb structures

A technology for honeycomb structure and defect inspection, which is applied in the direction of measuring devices, optical testing of defects/defects, and material analysis through optical means, and can solve problems such as sensitivity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

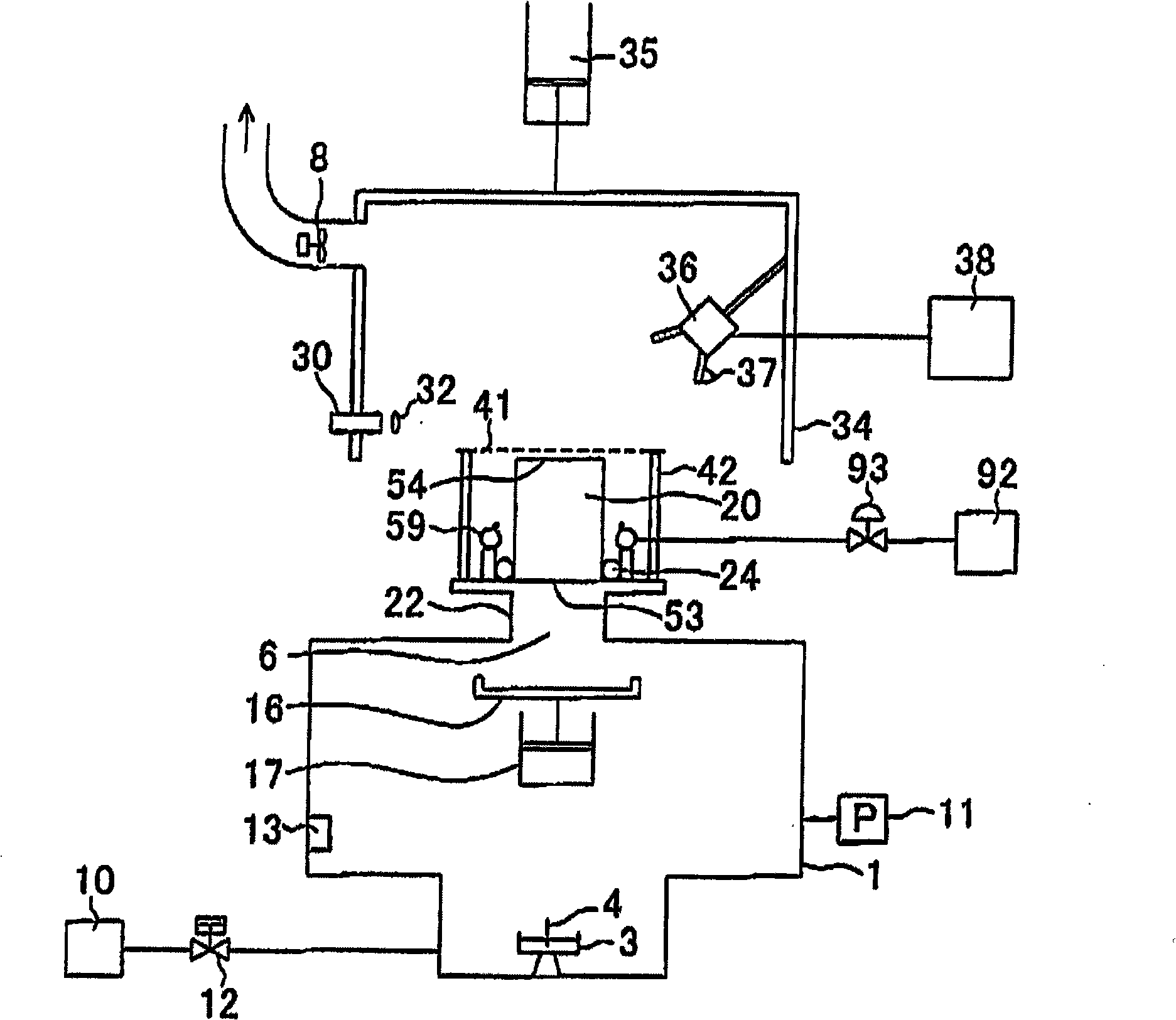

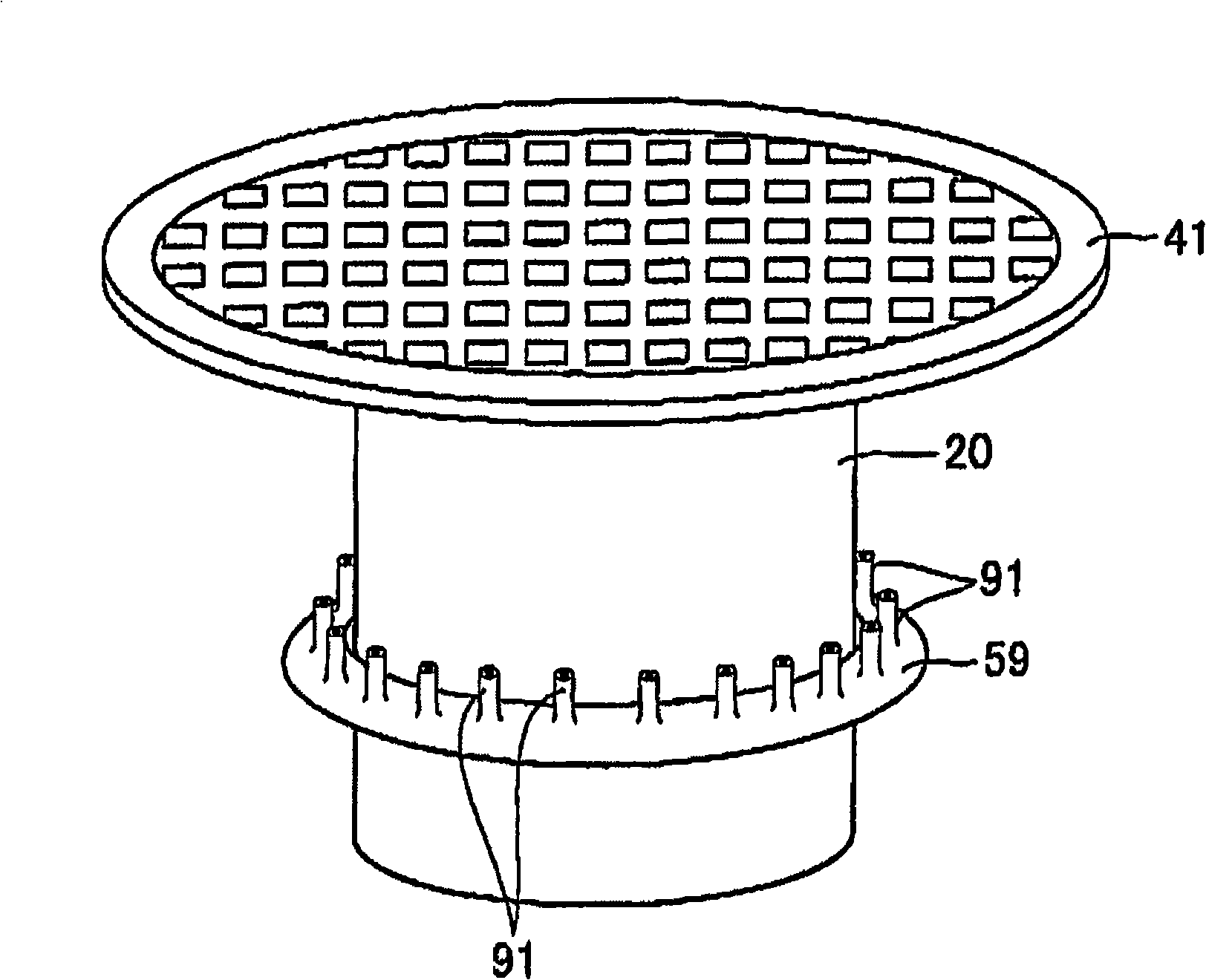

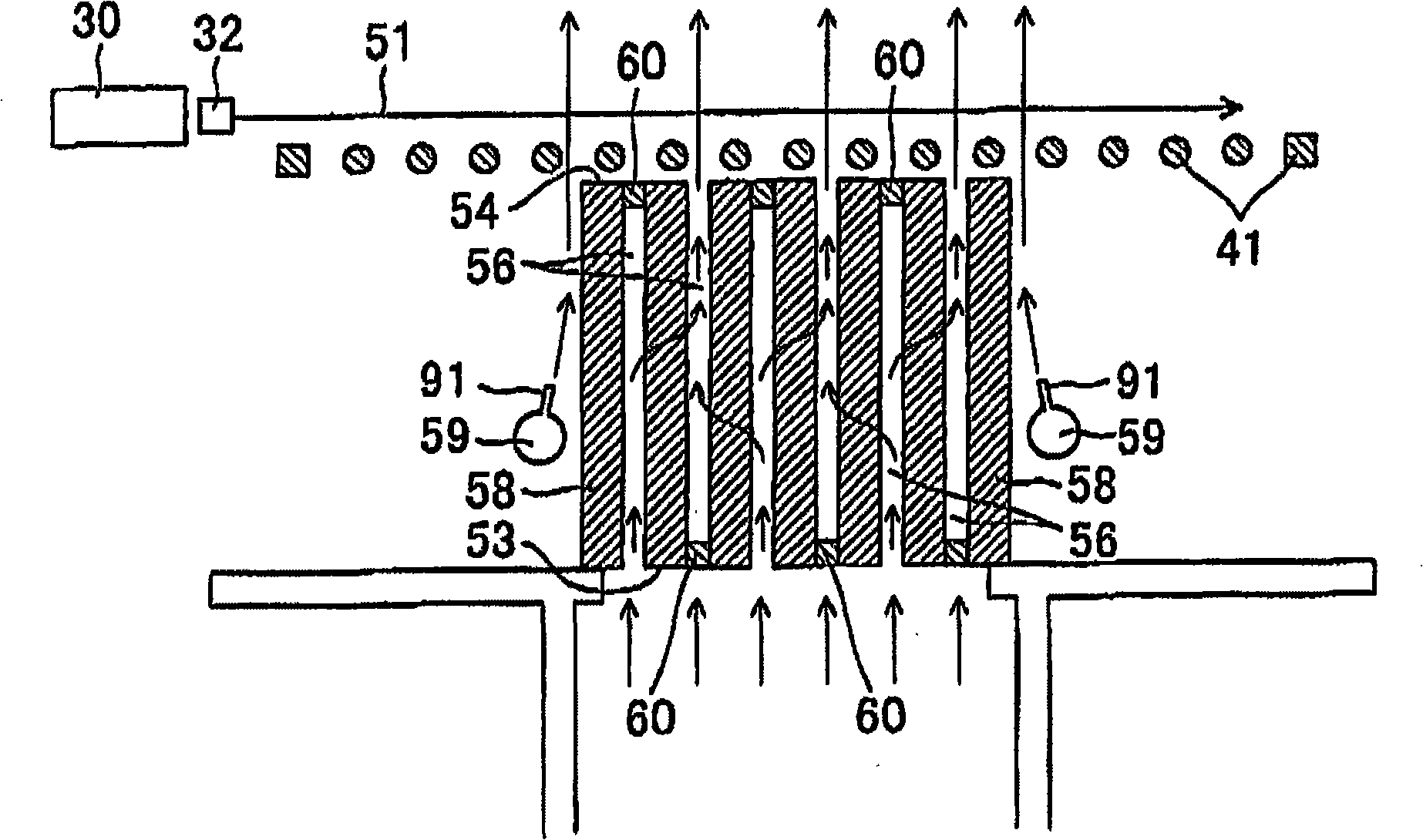

[0067] (Example 1) use figure 1 The illustrated honeycomb structure defect inspection device inspects defects of the honeycomb structure 20 which is a porous body. The honeycomb structure 20 as the subject is cylindrical with a diameter of 150 mm and a length of 150 mm, and the cell density is 40 cells / cm 2 , A sealed honeycomb structure used as a DPF was used. The rectifying plate 41 is a member plated with chrome on stainless steel, and a rectifying plate with 100 meshes and a hole interval of 50 μm is used, and it is arranged at a distance of 1 mm from the fine particle discharge surface 54 of the honeycomb structure. The airflow along the outer periphery of the honeycomb structure 20 is formed by sending air at 6 L / min from 32 nozzles 91 formed on the header 59 .

[0068] exist figure 1 A honeycomb structure is installed on an installation table 22 of the illustrated honeycomb structure defect inspection device using a seal 24 . Also, burning incense produces fine part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com