Tubular bus connector

A tubular busbar and connector technology, which is applied in the connection, conductive connection, electrical component connection, etc., can solve the problems of insulation safety hazards, poor shielding effect, heating of steel components, etc., to ensure connection reliability and large conductive contact surface. , the effect of high contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

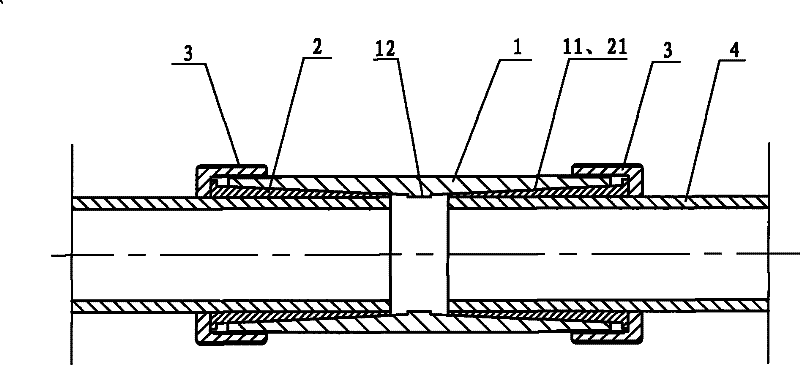

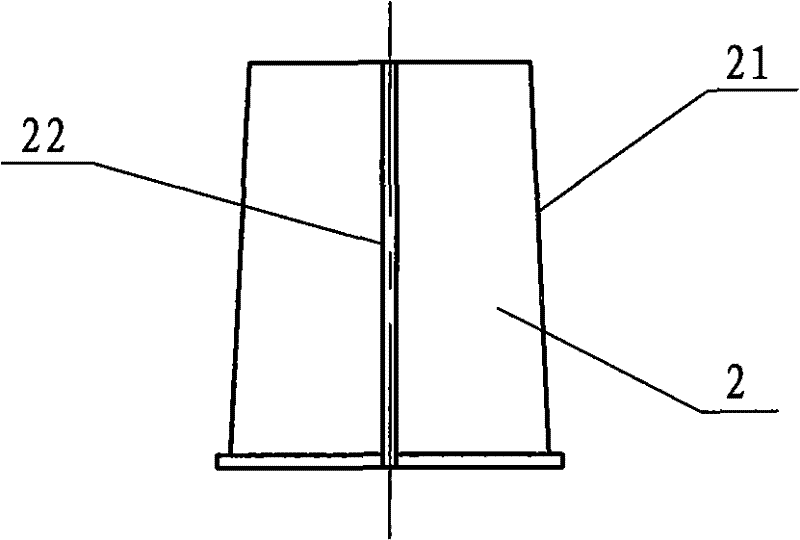

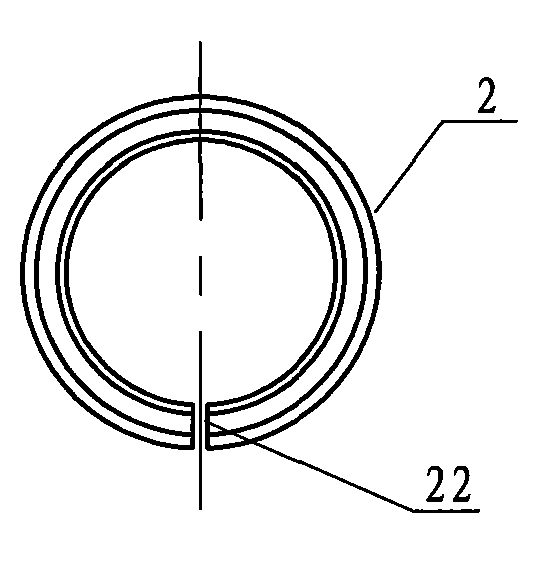

[0010] As shown in the figure, the tubular busbar connector includes a cylindrical intermediate conductor 1. The front and rear sections of the inner wall of the intermediate conductor are respectively provided with inner conical surfaces 11 with larger outer diameters. There is an inner taper sleeve 2 matched with it, the inner hole of the inner taper sleeve is a round hole matching the outer diameter of the tubular busbar 4, and the outer wall of the inner taper sleeve 2 has an inner conical surface 11 to match the intermediate conductor 1 The outer conical surface 21 of the inner cone sleeve also has an axially through slot 22 (such as figure 2 , image 3 Shown); at the two ends of the intermediate conductor 1, end caps 3 are respectively arranged, and the end caps and the intermediate conductor are connected by thread fit, and the inner side of the end cap is pressed on the outer end surface of the inner tapered sleeve 2. During use, the tubular busbar 4 is inserted from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com