Facing explosion resistant, bulletproof and violence resistant hollow sandwich compound glass and method for manufacturing same

A technology of composite glass and laminated glass, which is applied in the field of bulletproof, anti-violence hollow laminated composite glass, anti-face explosion, and hollow laminated composite glass. Thickness and other issues, to achieve the effect of reducing the thickness size, optimizing the product structure, and improving the preventive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

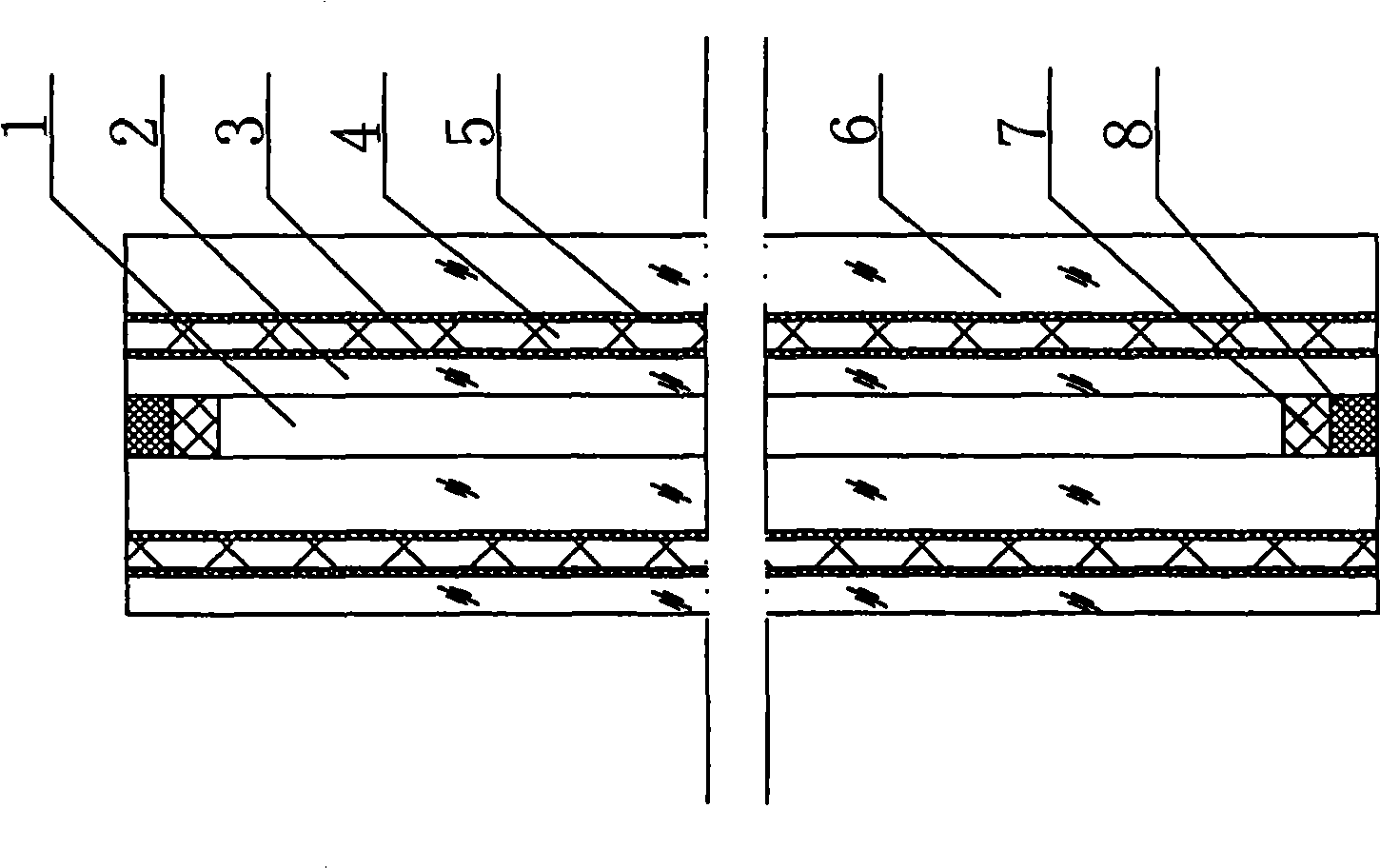

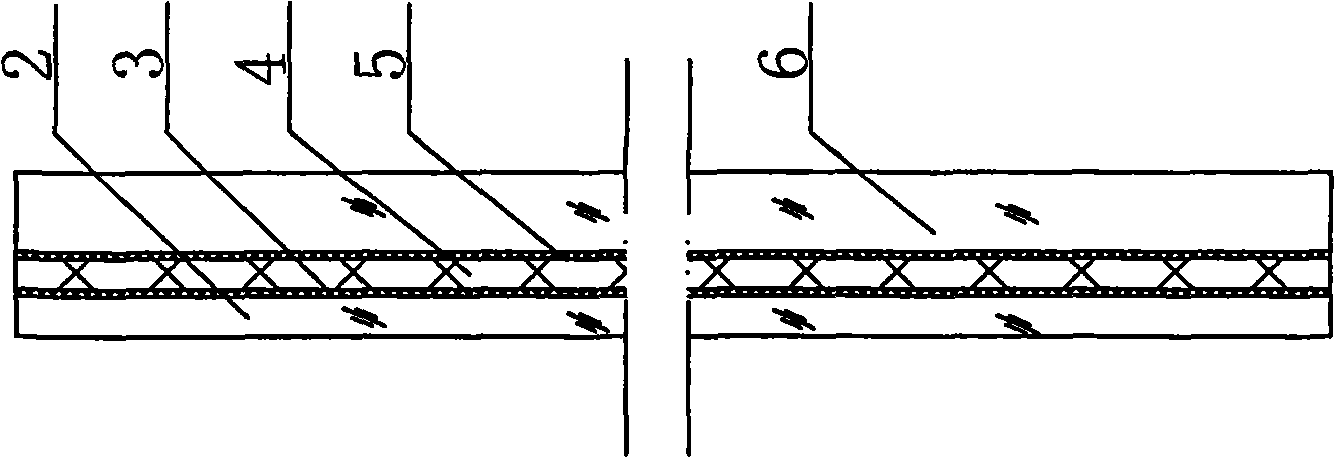

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Depend on figure 1 and figure 2 It can be seen that the composite laminated glass unit has a five-layer structure, which is glass 6, PU film 5, PC board 4, PU film 3, and glass 2. Adhesive film 3, then glass 6 is covered on PU adhesive film 5, glass 2 is covered on PU adhesive film 3, glass 6, PU adhesive film 5, PC board 4, PU adhesive film are laminated glass process by heating and pressing etc. 3. The glass 2 is composited into an integral unit, the PU film 5 and the PU film 3 are made of PVB glue, and the PC board 4 is made of an SPC board.

[0017] Depend on figure 1 and figure 2 It can also be seen that the anti-face explosion, bulletproof and anti-violence hollow laminated composite glass is provided with two sets of composite laminated glass units, and the upper and lower ends of each group of composite laminated glass un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com