Plate bending machine capable of automatically adjusting multiunit upper supporting roller device

An automatic adjustment and rolling machine technology, which is applied in the field of forging machinery, can solve the problems of not being able to fully adhere to the bottom plane of the girder, difficulty in balancing, and inconvenient operation, etc., to shorten the preparation time of the rolling plate, improve the precision, and improve the rolling operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

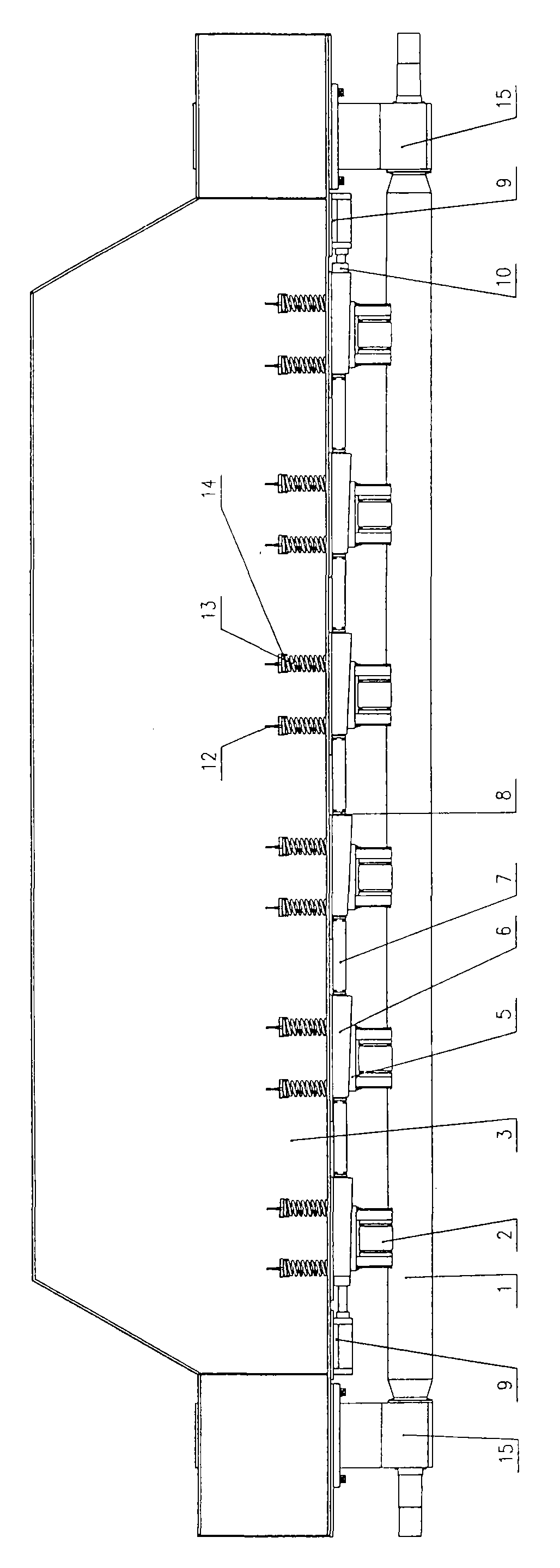

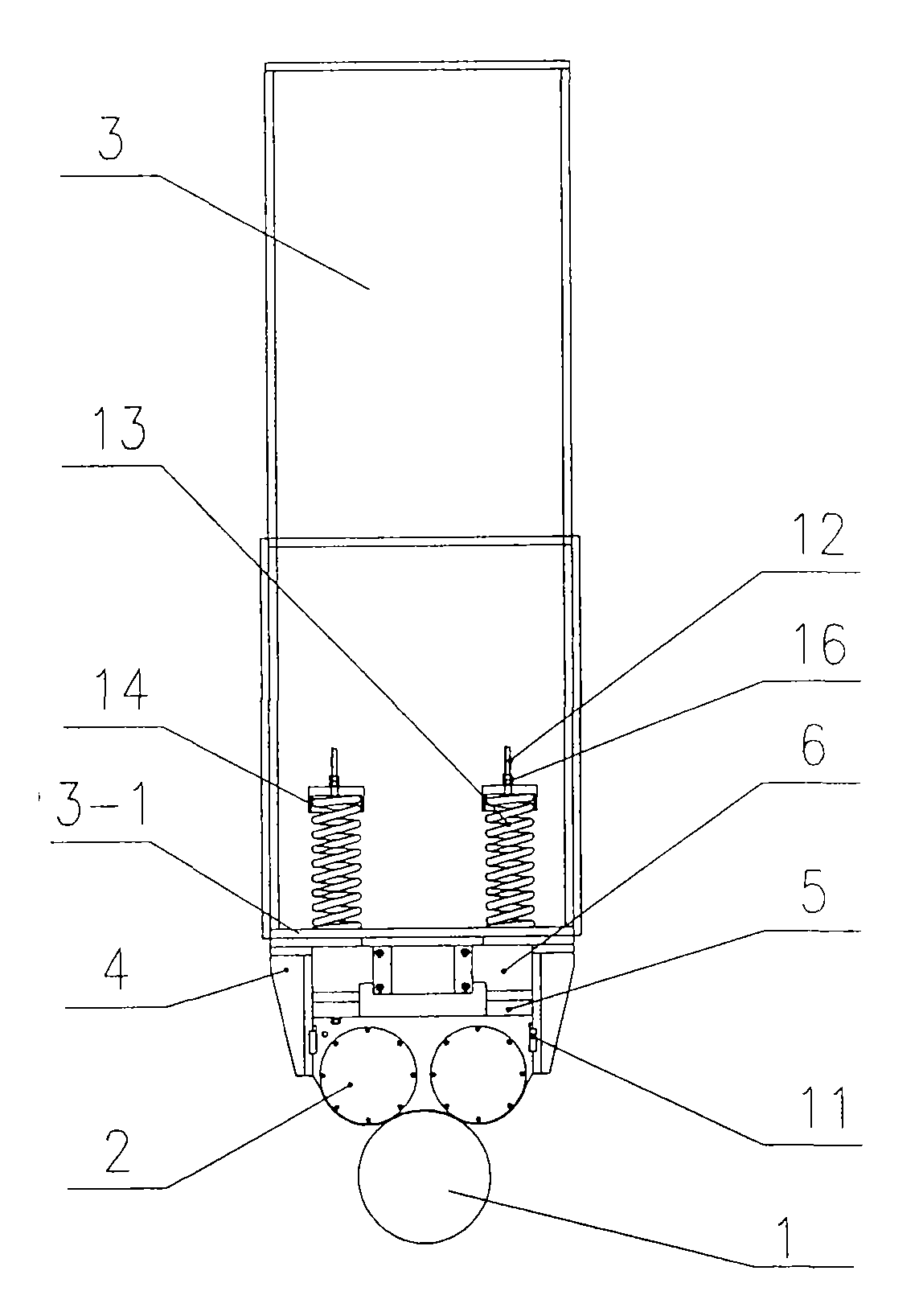

[0012] Such as figure 1 , 2 As shown, the girder 3 is provided with a bottom plate 3 - 1 , and the upper roller 1 is supported by two sets of bearings 15 at both ends under the girder 3 . Multiple sets of upper roller devices 2 are arranged between the upper roller 1 and the girder 3 .

[0013] The lower ends of the two ends of the girder 3 are fixedly connected to the oil cylinders 9 respectively. The telescopic rods of the two groups of oil cylinders 9 are coaxially opposite and parallel to the upper roller 1. Between the two telescopic rods of the two groups of oil cylinders 9, the connecting beam 7 is connected by a connecting block 10. , fixedly connect seven vertically inclined irons 6 along the length direction of the connecting beam 7 on the connecting beam 7 .

[0014] Positioning seats 4 are respectively fixed on the front and rear sides of the lower end of the girder 3 , and vertical key grooves are respectively arranged on the two inner sides opposite to the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com