Auxiliary packing machine for cigarette packet transparent paper and cigarette packet conveying system thereof

A conveying system and transparent paper technology, applied in the directions of packaging cigarettes, packaging, conveyor objects, etc., can solve the problems of front and rear cigarette pack collision, and achieve the effects of reducing mechanical impact force, increasing cigarette pack density, and reducing belt speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

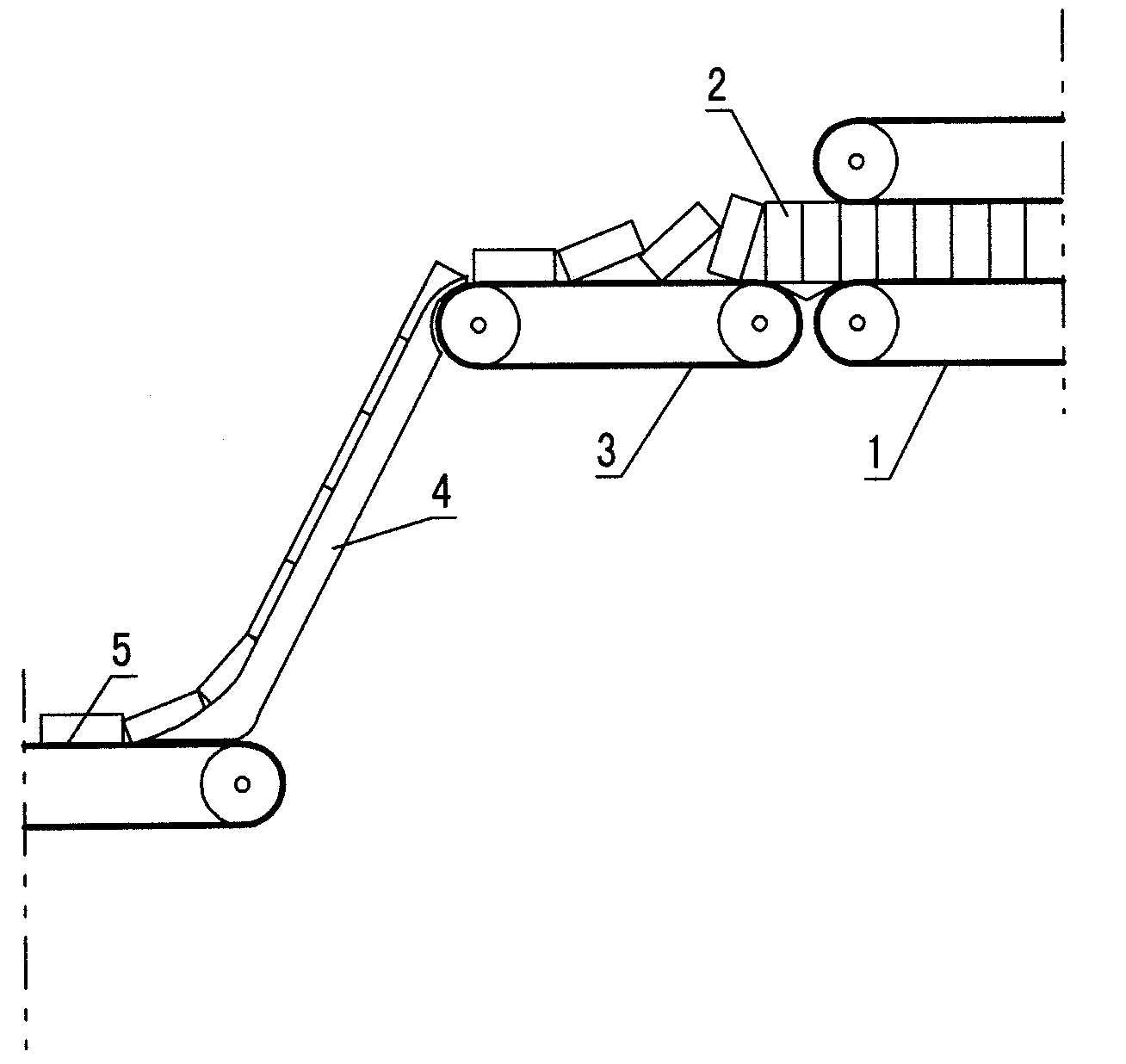

[0015] Such as figure 1 As shown, the corresponding packaging machine exit 1 is connected with a differential cigarette pack transverse conveying belt 3 that is consistent with its cigarette pack movement direction. The bag 2 is adjusted from horizontal vertical side by side to horizontal horizontal side by side. The rear portion of the differential cigarette bale horizontal delivery conveyor belt 3 is connected with a cigarette bale glide trough plate 4 , and the bottom end of the cigarette bale glide chute plate is connected with a cigarette bale horizontal delivery conveyor belt 5 .

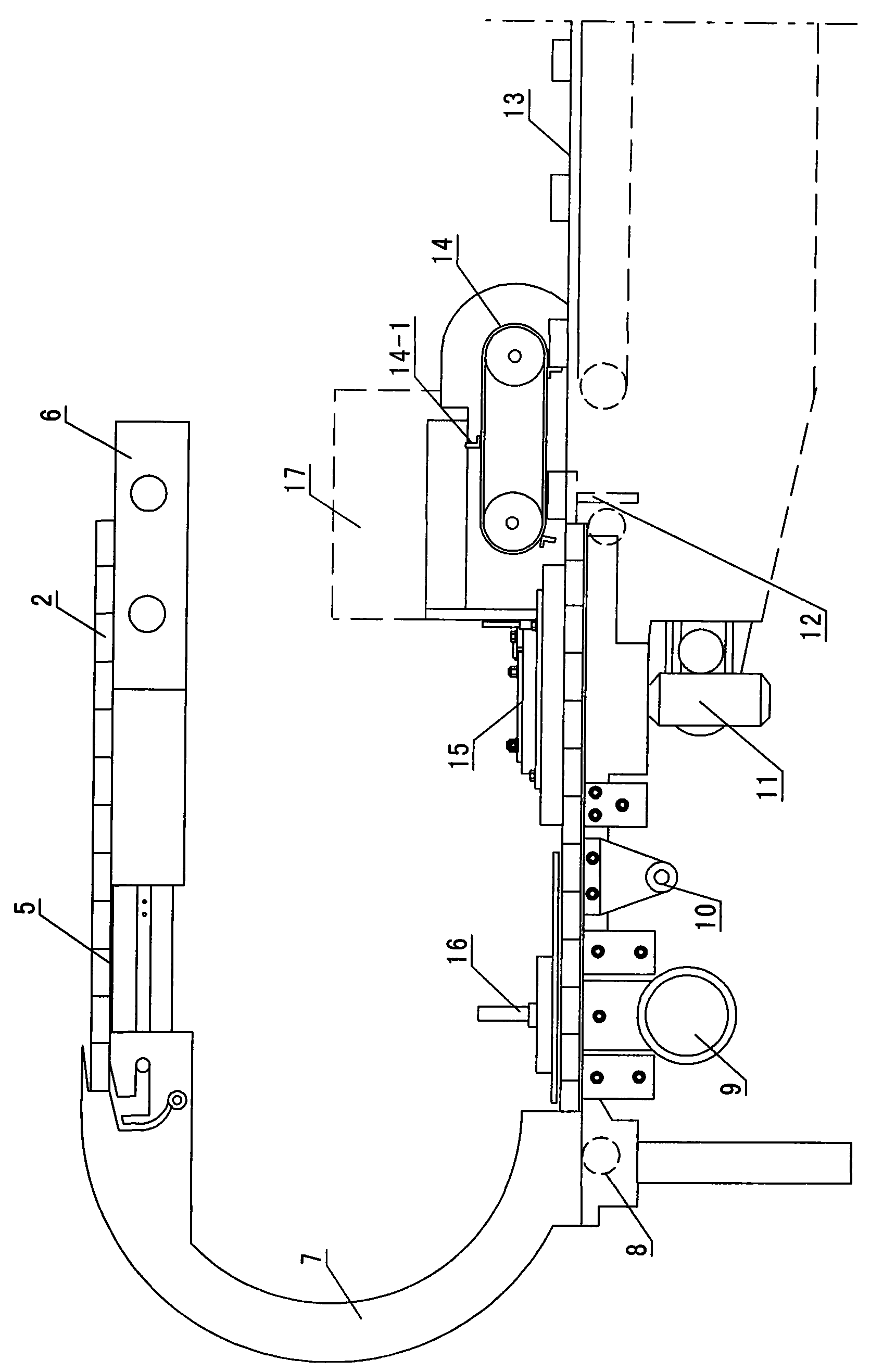

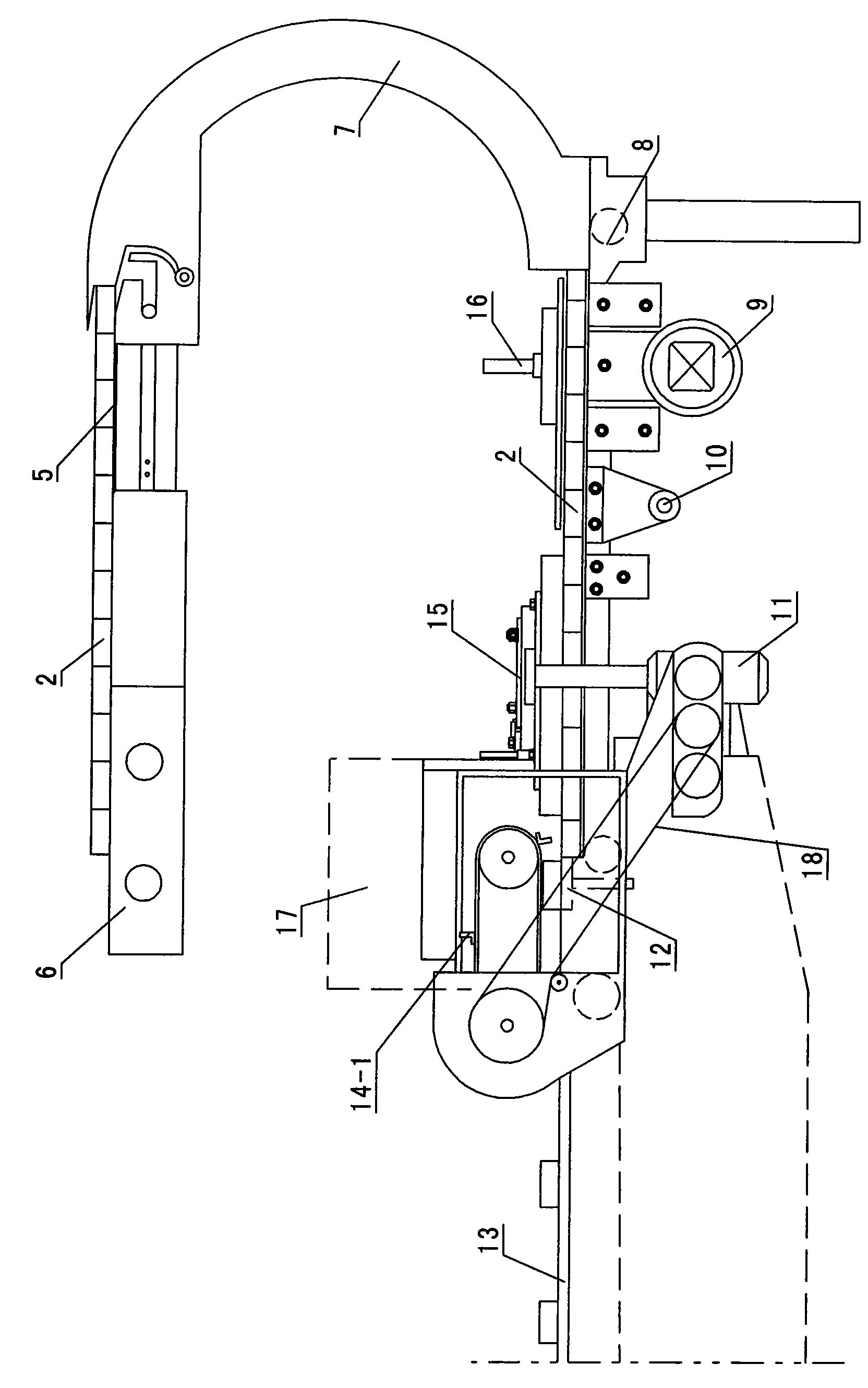

[0016] Such as figure 2 , 3 as shown, figure 1 The rear portion of the cigarette bale cross-feed conveyor belt 5 is connected with a corner 6 positioned at 90° above the transparent paper packaging auxiliary machine, and the rear portion of the corner 6 is connected with the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com