Clutch mechanism

A clutch mechanism and clutch device technology, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as injury to the patient or surgeon of the carrier, and increase the risk of misoperation of the carrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

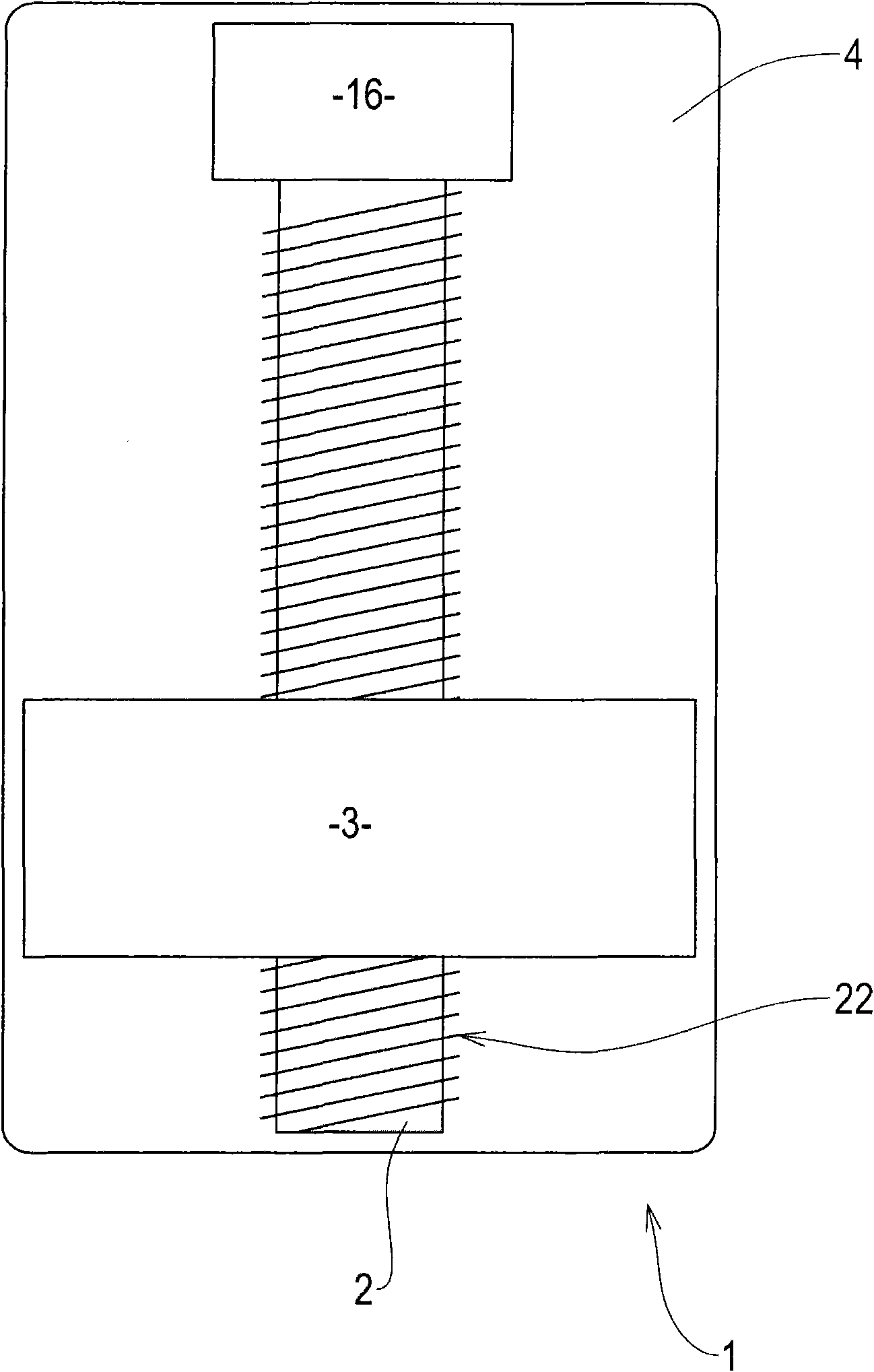

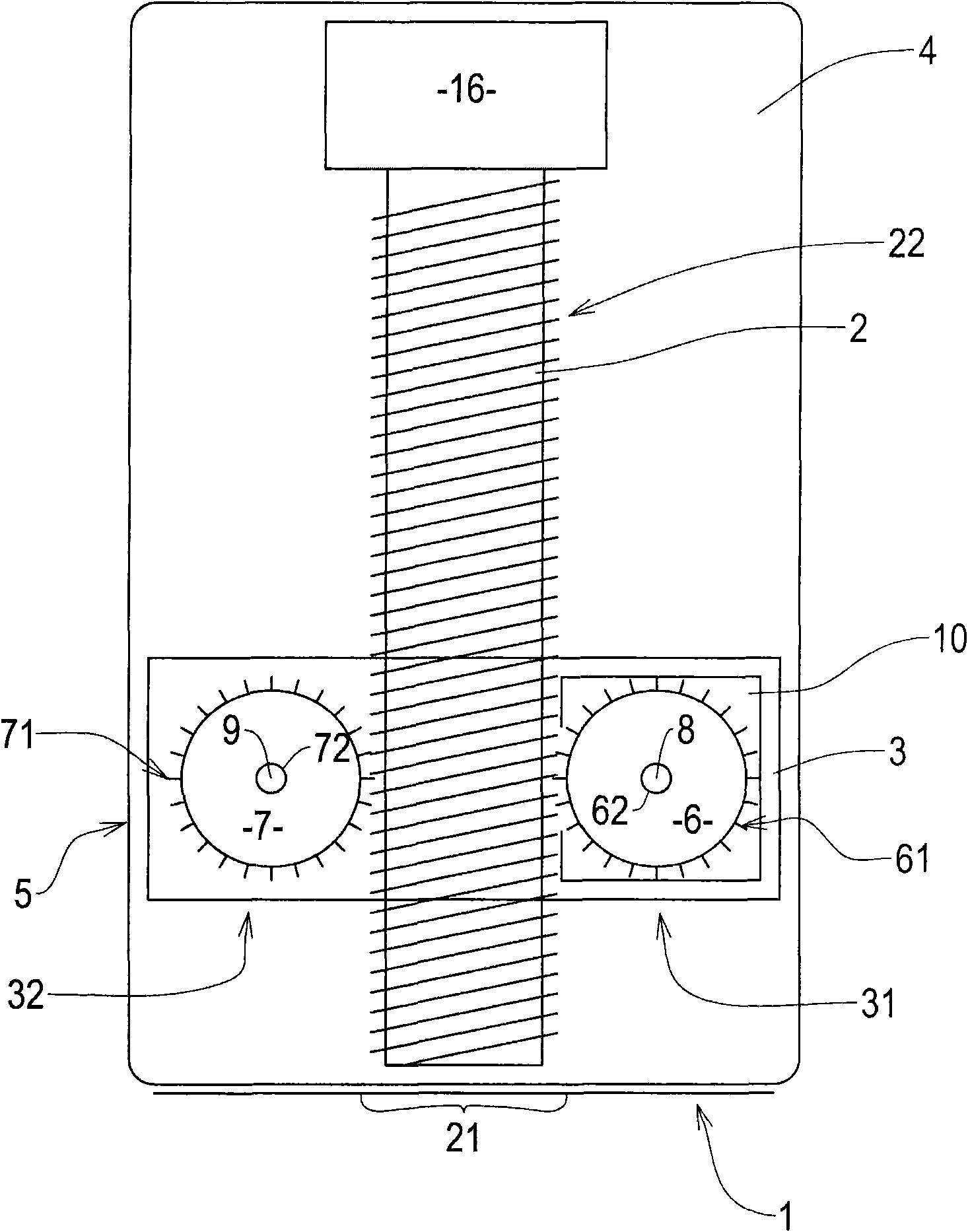

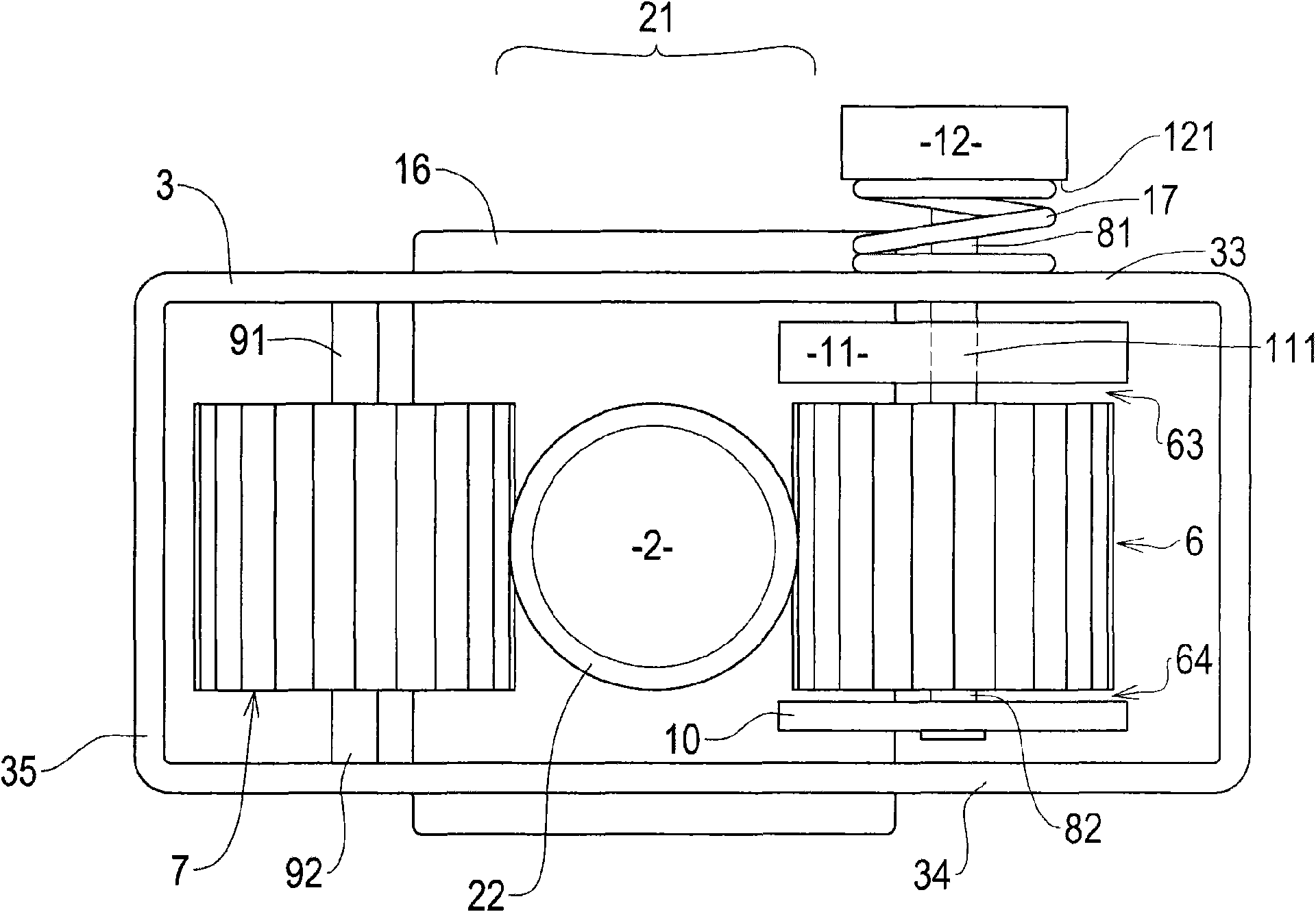

[0029] refer to figure 1 , an embodiment of the present application includes a linear drive device 1 .

[0030] The linear drive device 1 comprises a threaded shaft 2 and a motor 16 connected to the threaded shaft, activating the motor 16 causes the threaded shaft 2 to rotate. Preferably, the motor 16 is connected to the proximal end of the threaded shaft 2 . This connection can be achieved through the use of a gearbox (not shown) or through a direct connection.

[0031] The threaded shaft 2 and the motor 16 are installed in the housing 4 . The motor 16 is fixed to the housing 4 and is prevented from rotating relative to the housing. This can be achieved eg by using adhesive or one or more screws. Alternatively, motor 16 may have a base (not shown) integrally formed with housing 4 . Other installations are also possible.

[0032] The threaded shaft 2 is driven by a motor 16 to rotate freely relative to the housing 4 . In one embodiment, a bearing (not shown) is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com