Automatic expansion compensation type pipe joint

A pipe joint and compensation type technology, which is applied in the expansion compensation device for pipelines, pipes/pipe joints/fittings, pipe components, etc., can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

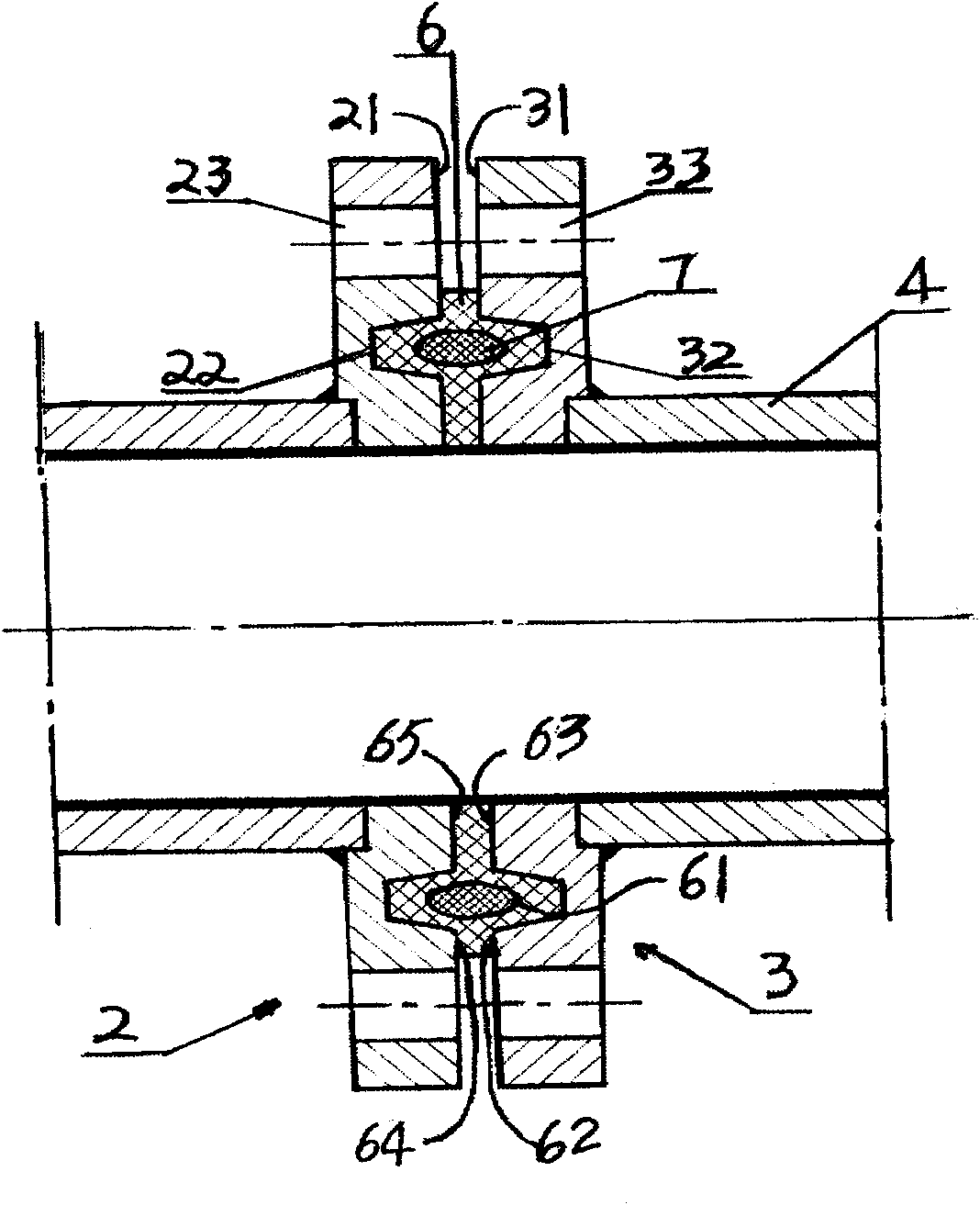

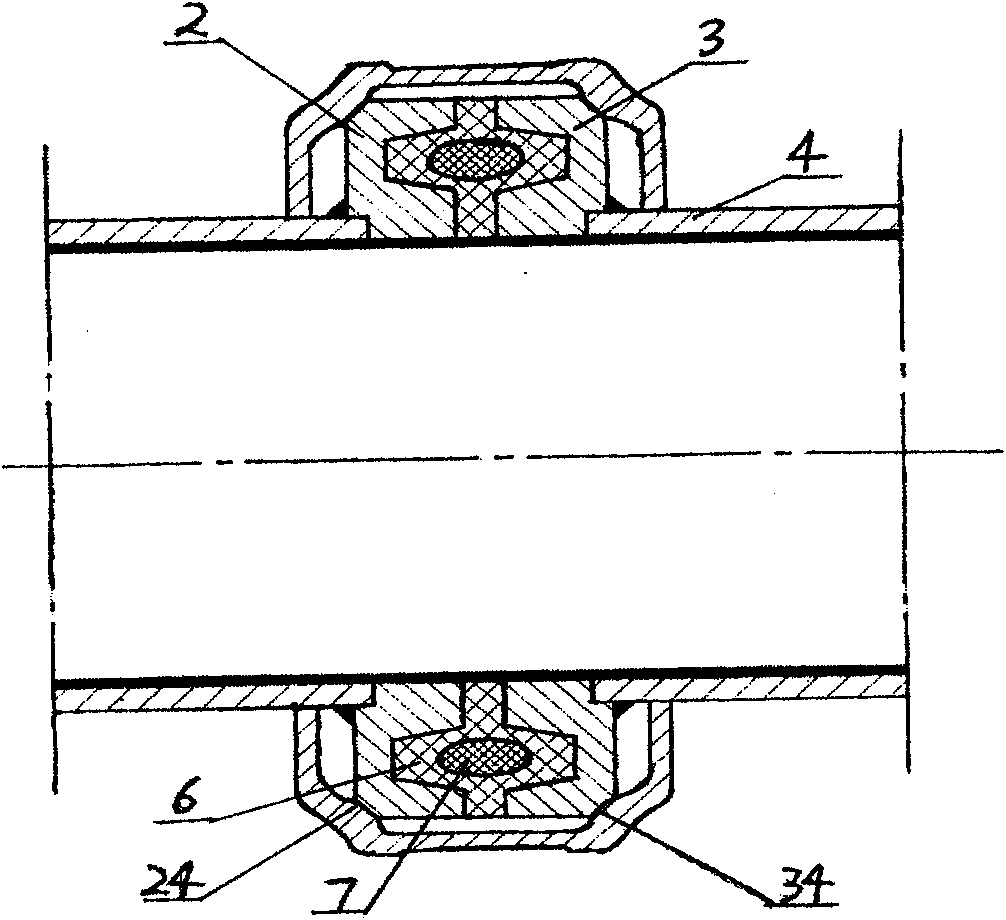

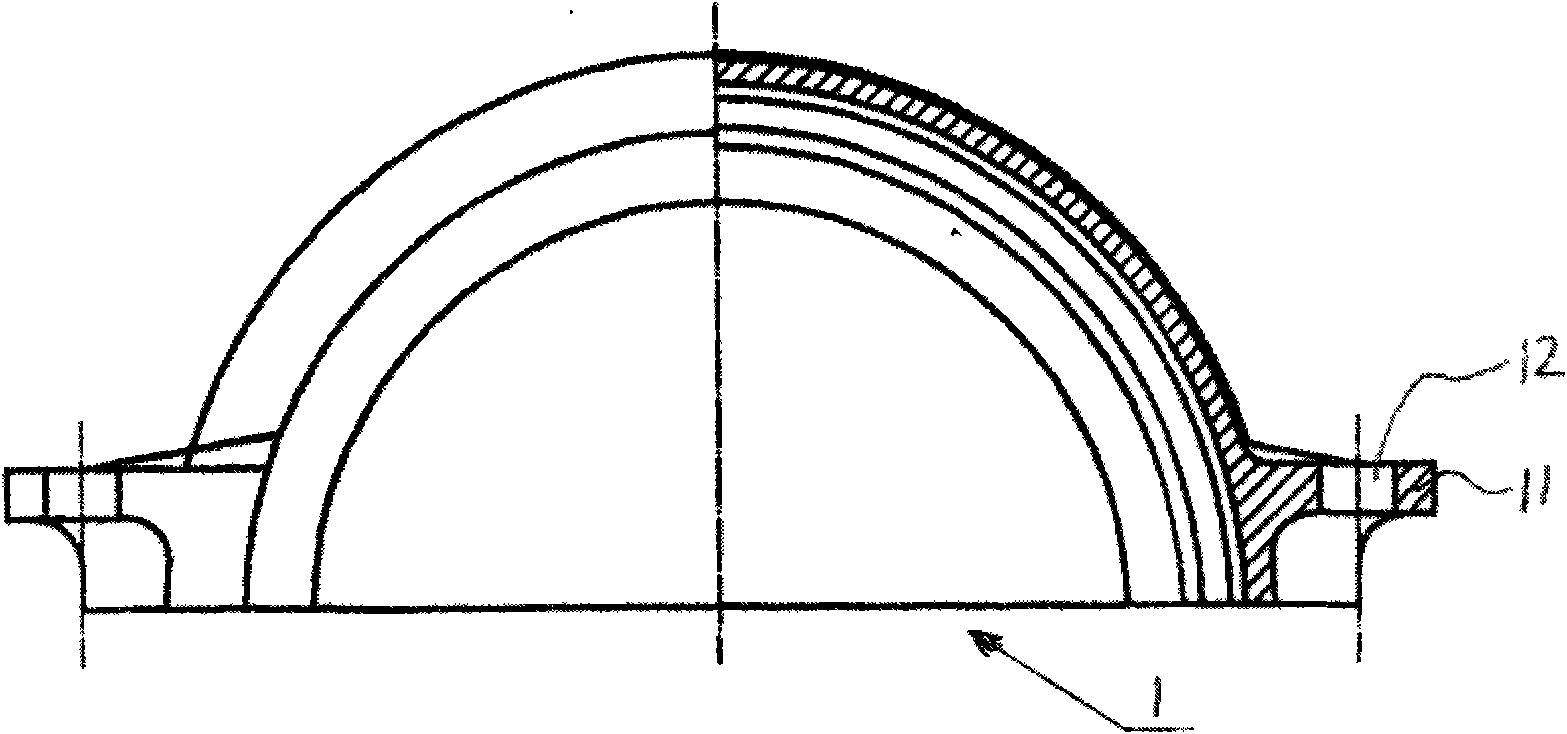

[0019] see figure 1 and Figure 5 , these two drawings show the overall structure of the appearance of the first embodiment of the self-expansion compensating pipe joint proposed by the present invention. The pipe joint includes a first joint part 2 and a second joint part 3 respectively arranged at the ends of two pre-connected pipes 4 , and an elastic sealing part 6 .

[0020] The first joint part 2 and the second joint part 3 can be made into a structure similar to that of flanges in the prior art, that is, they are made of disc-shaped plates, and axial through holes 23 and 33 are arranged on them. . Corresponding annular recesses 22 and 32 are respectively provided on the abutting end surfaces 21 and 31 of the first joint part 2 and the second joint part 3 . An elastic sealing member 6 is respectively installed in the annular recesses 22 and 32 , and each elastic sealing member 6 is provided with an annular groove 61 perpendicular to the annular recesses 22 and 32 and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com